Self-lubricating bearing pedestal

A technology of self-lubricating bearings and bearing housings, applied in bearings, bearing components, shafts and bearings, etc., can solve the problems of self-lubricating agents that cannot be evenly coated, and achieve the effects of avoiding outflow, reducing friction, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

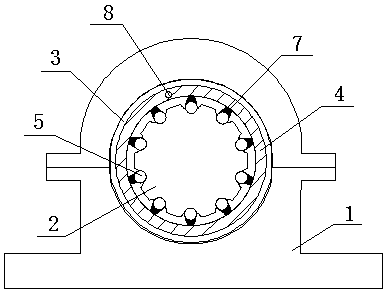

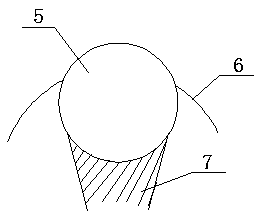

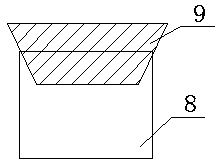

[0015] Such as figure 1 It is a structural schematic diagram of the present invention, a self-lubricating bearing housing, including a bearing housing main body 1 and a bearing bush 3 arranged in the central shaft hole 2 of the bearing housing main body 1, and a lubricating ring 4 filled with lubricating oil is arranged inside the bearing bush 3, and the lubricating ring 4. It communicates with the outside world through the ball 5 used for fluid conduction arranged on the inner wall of the bearing bush 3. The inner wall of the bearing bush 3 is provided with a notch for installing the ball 5. The notch communicates with the lubricating ring 4 through the corresponding oil delivery channel 7 to lubricate. The inner wall of the ring 4 is coated with protective paint. During installation and use, the upper and lower bearing seats are covered by bolts, and the bearing bush 3 is fixed in the central shaft hole. There is a lubricating ring 4 inside the bearing bush 3 for filling lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com