Door body sealing device of ball rolling machine

A technology of a sealing device and a ball rolling machine, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as impact on the sealing of the outer casing, time-consuming and laborious, and damage to the sealing strip, and achieve high practicability, high creativity, and Simple structure and novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

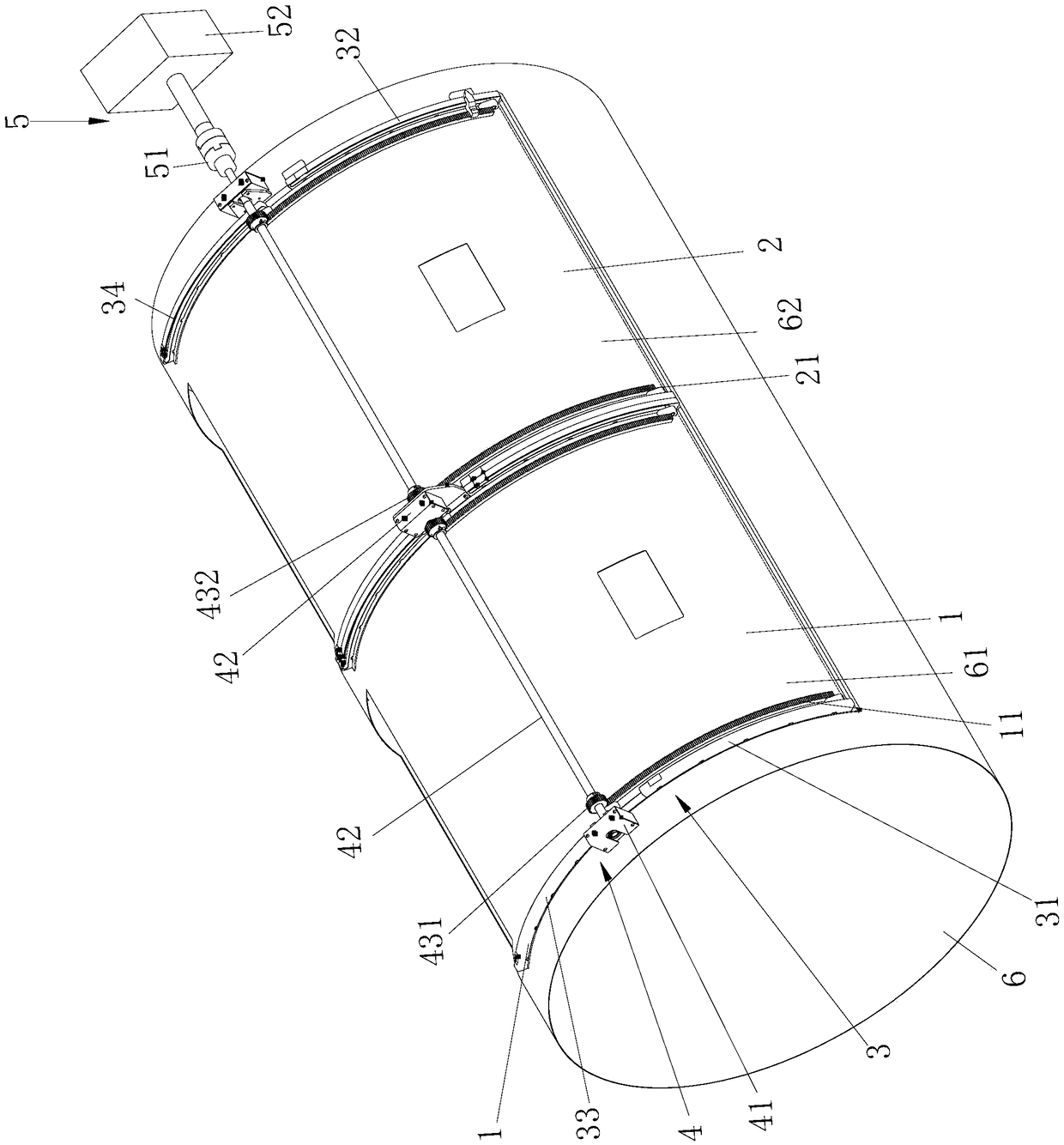

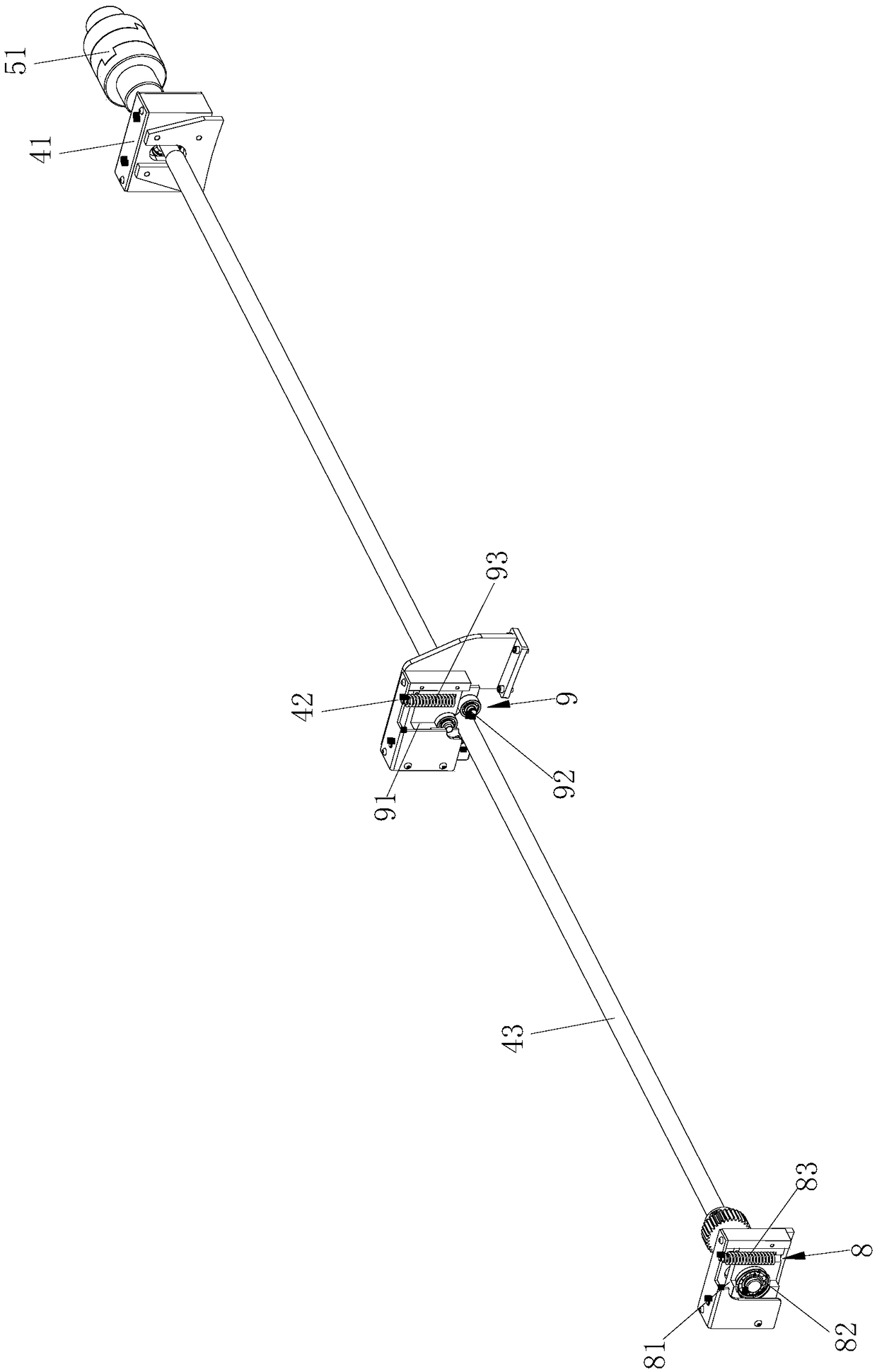

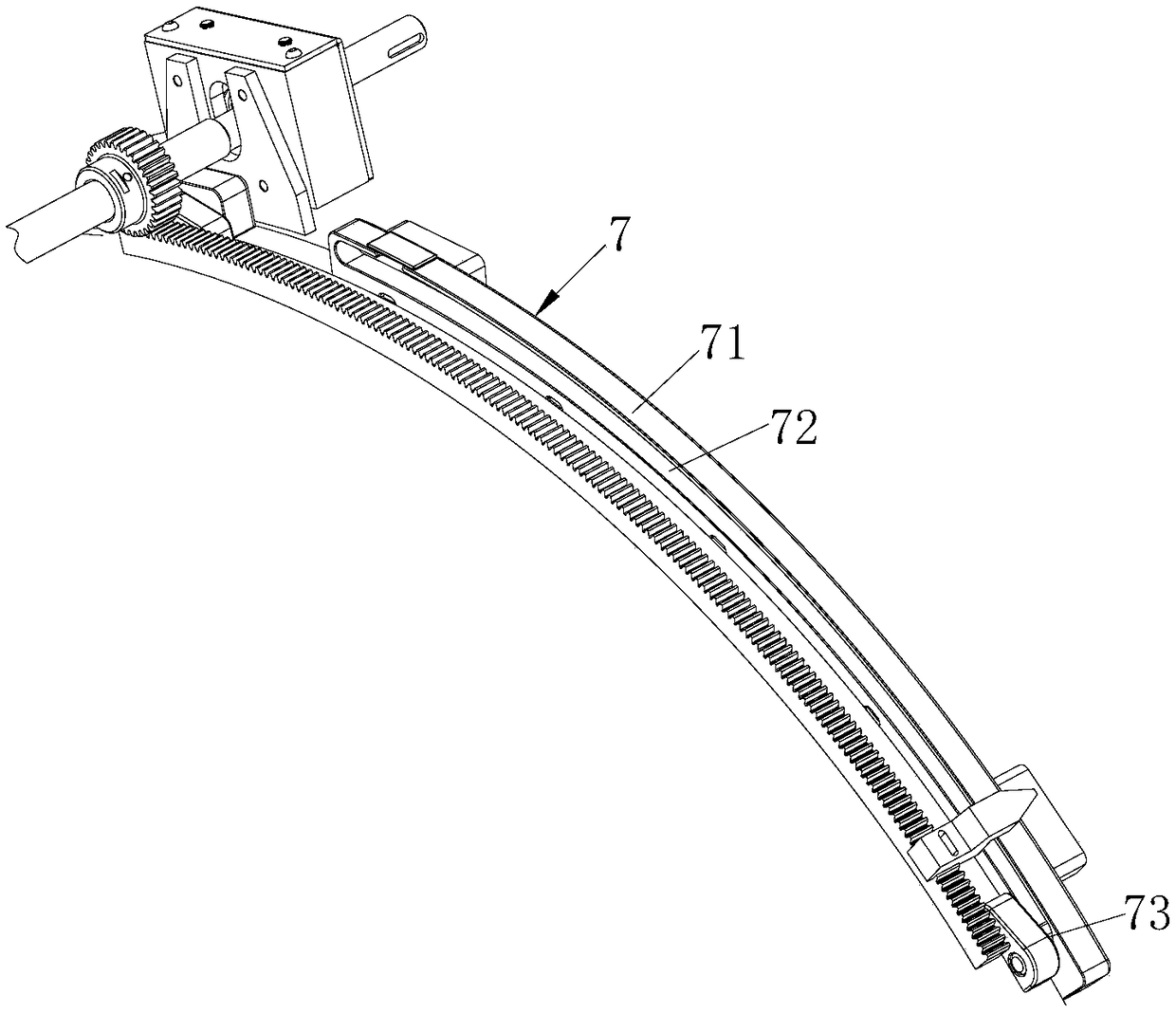

[0026] combine Figure 1 to Figure 6 , a door body sealing device for a rolling ball machine, including a first door body 1, a second door body 2, a sliding mechanism 3, a transmission mechanism 4 and a power mechanism 5. A first notch 61 and a second notch 62 are provided on the side wall of the casing 6 of the ball rolling machine, the first door body 1 is arranged on the first notch 61 , and the second door body is arranged on the second notch 62 superior. The casing 6 of the ball rolling machine is cylindrical. The sliding mechanism 3 includes a first slide rail 31 and a second slide rail 32, the first slide rail 31 is connected to the casing 6 at the left end of the first notch 61, and the second slide rail 32 is connected to the side end of the second notch 62. On the casing 6.

[0027] The casing 6 on the upper side of the first slide rail 31 is provided with a thir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com