Sampling device of urine analyzer

The technology of a urine analyzer and sampling device, which is applied in the direction of analyzing materials and instruments, can solve the problems of uneven sample addition, inaccurate judgment results, and high degree of manual participation, so as to improve detection accuracy and automation, and avoid sample addition Uneven, reducing the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

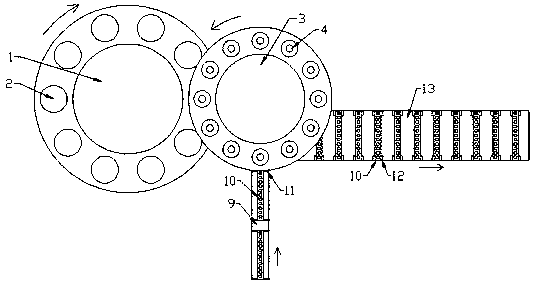

[0025] Such as figure 1 The illustrated sampling device of a urine analyzer includes a sample tray 1, a sample adding mechanism, a vertical conveying mechanism and a horizontal conveying mechanism arranged at the end of the vertical conveying mechanism in the conveying direction.

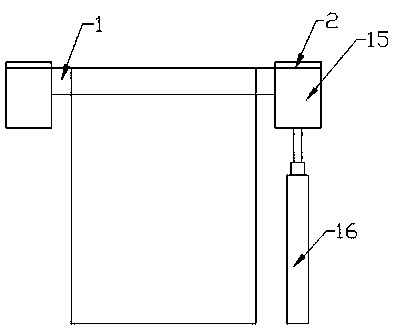

[0026] The sample tray 1 is provided with urine cup holes 2 evenly arranged on the same ring, and a urine cup 15 is placed in the urine cup hole 2; the sample tray 1 is connected to the output end of the drive motor 1 through a rotating shaft, and the The driving motor is driven to rotate and positioned by controlling the driving motor in one step; the urine cup hole 2 on the far right side of the sample tray 1 is provided with a lifting cylinder 16, and the lifting cylinder 16 can push the urine cup 15 to move up and down; figure 2 As shown, when the urine cup 15 turns to the top of the lifting cylinder 16, the lifting cylinder 16 works to push the urine cup 15 to move up to the liquid inlet of th...

Embodiment 2

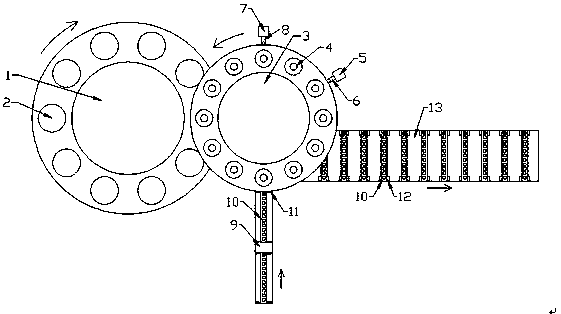

[0031] Such as image 3 , Figure 4 As shown, a sampling gun head 14 is detachably connected to the bottom of the micro-sampler 4, and a support rod one 5 and a support rod two 7 are sequentially arranged along the rotation direction of the sample loading turntable 3; the support rod one 5 is provided with The sampling gun head is separated from the plate 6, and when the sampling gun head is separated from the plate 6 and moves downward, the sampling gun head 14 is separated from the micro sampler 4; the supporting rod 2 7 is provided with a sampling gun head mounting plate 8. When the sampling gun head mounting plate 8 moves upward, the clean sampling gun head 14 is installed on the micro-sampler 4; as Figure 5 , Figure 6 As shown, the disengagement plate 6 and the mounting plate 8 of the sampling gun head are driven by gears and chains so that they can move circularly along a square track in a vertical plane; the rest of the structure is the same as that of Embodiment 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com