A cutting head connection structure and modification method

A technology of connecting structure and cutting head, which is used in cutting machinery, earth-moving drilling, elastic coupling, etc., can solve the problems of uneven bearing capacity of spline parts, equipment cannot be put into use, and production efficiency is reduced. The effect of low cost, simple structure and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

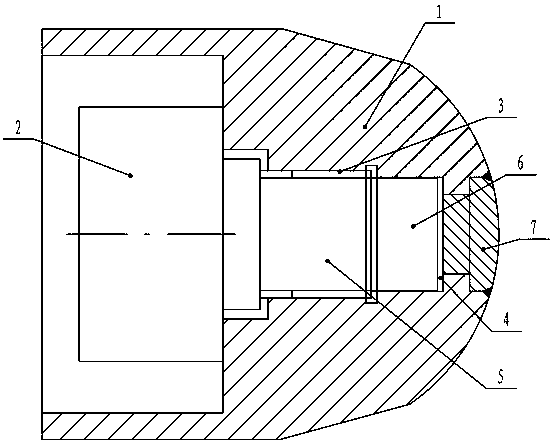

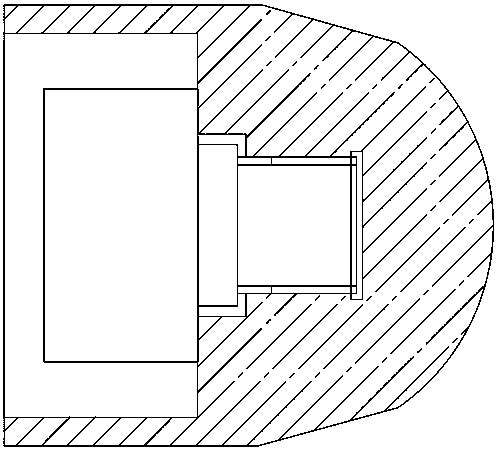

[0025] Embodiment 1: as Figure 1-4 As shown, a cutting head connection structure, including a cutting head 1 and a transmission shaft 2, the cutting head 1 is provided with an internal spline 3, and the inner end of the internal spline 3 is provided with a blind shaft coaxial with the internal spline 3. Hole 4, the transmission shaft 2 is provided with a spline 5, the spline 5 is embedded in the inner spline 3 to mesh with it, and an auxiliary support cylindrical rod 6 coaxial with the transmission shaft 2 is provided at the end, and the auxiliary support cylindrical rod 6 extends into the blind hole 4 and maintain a clearance fit.

[0026] Preferably, the above-mentioned blind hole 4 has a depth of 125-130 mm, and the extension length of the auxiliary support cylindrical rod 6 is 3-5 mm less than the depth of the blind hole 4, which can satisfy the bearing capacity.

[0027] Preferably, the inner diameter of the above-mentioned blind hole 4 and the outer diameter of the aux...

Embodiment 2

[0028] Embodiment 2: as Figure 1-4 Shown, a kind of transformation method of cutting head connection structure, this method comprises the following steps:

[0029] (1) Remove the three pick seats at the end of the cutting head to be modified by gas cutting;

[0030] (2) Find the center of the spherical crown end of the cutting head, and drill a hole with a diameter of 70-80mm;

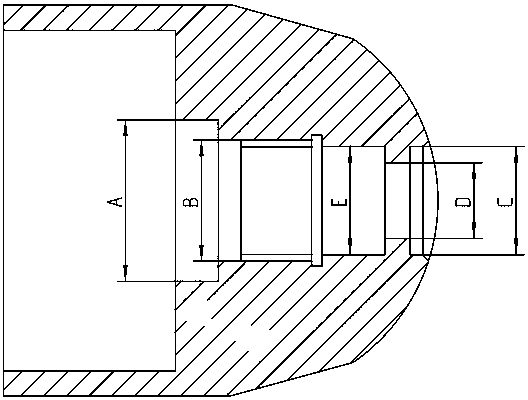

[0031] (3) Install, fix and align the cutting head on the boring machine, taking the cylindrical surface at A∅320 and B∅240 as the benchmark;

[0032] (4) Machining stepped circular holes with sizes C, D and E in the axial direction of the center of the spherical crown end;

[0033] (5) Use the plugging cover 7 to close the stepped hole of and the blind hole formed at the inner end of the spline in the cutting head;

[0034] (6) Weld the three pick holders cut off at the end of the cutting head in step (1) to the cutting position, and align them before welding;

[0035] (7) Set the spline end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com