Rectangular baler yield monitoring system and yield monitoring method based on Beidou/GPS technology

A technology of GPS receiver and baler, which is applied in radio wave measurement system, electric/magnetic area measurement, satellite radio beacon positioning system, etc., and can solve problems such as vibration interference, baler shake, uneven working ground, etc. , to achieve enhanced reliability, convenient and accurate management, improved accuracy and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

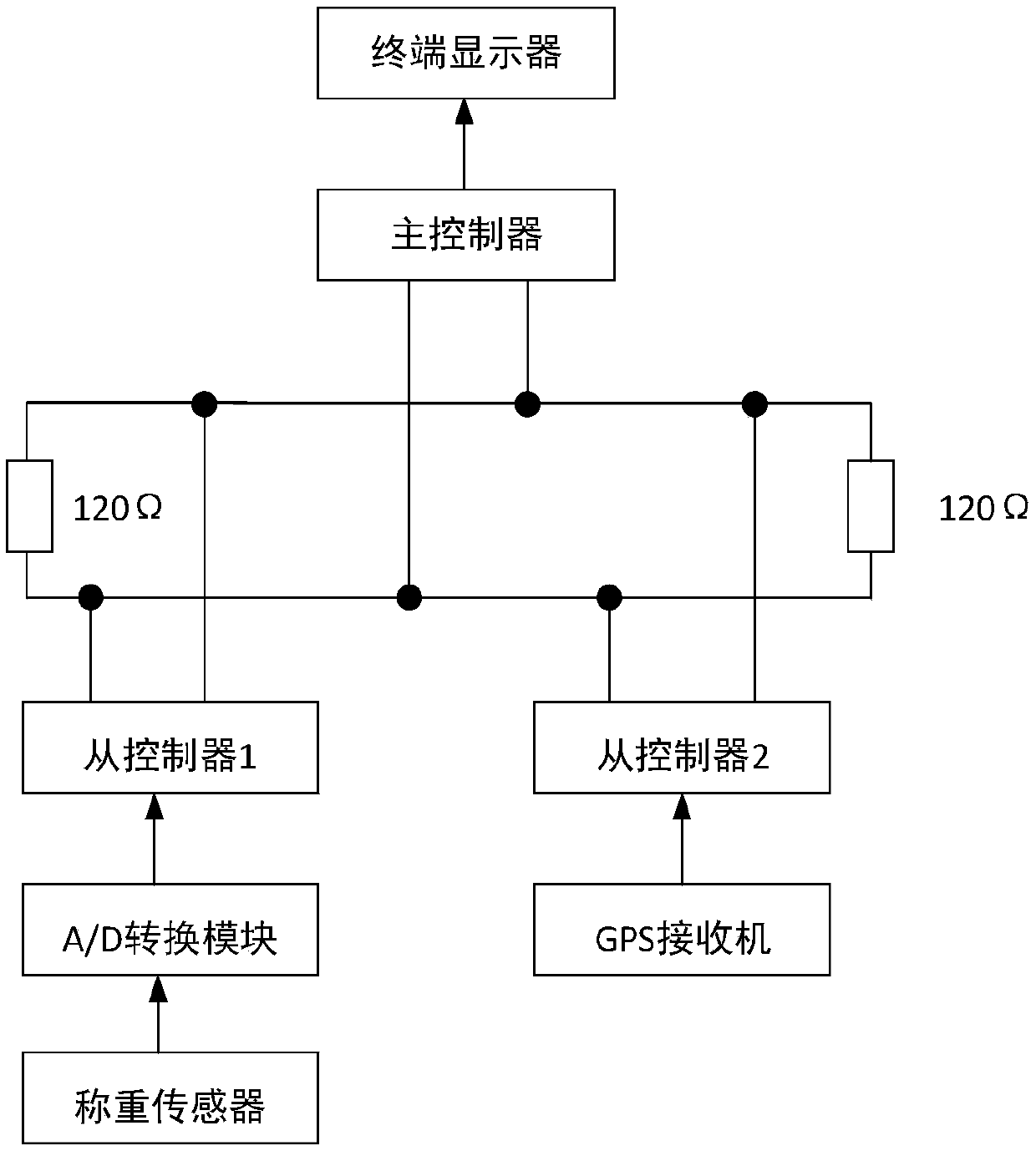

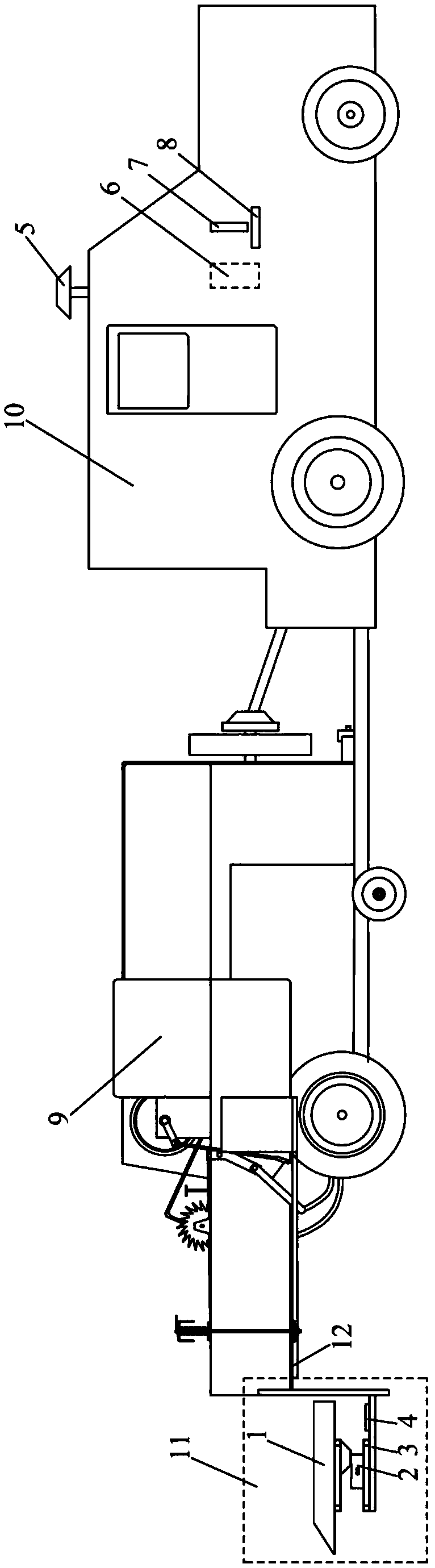

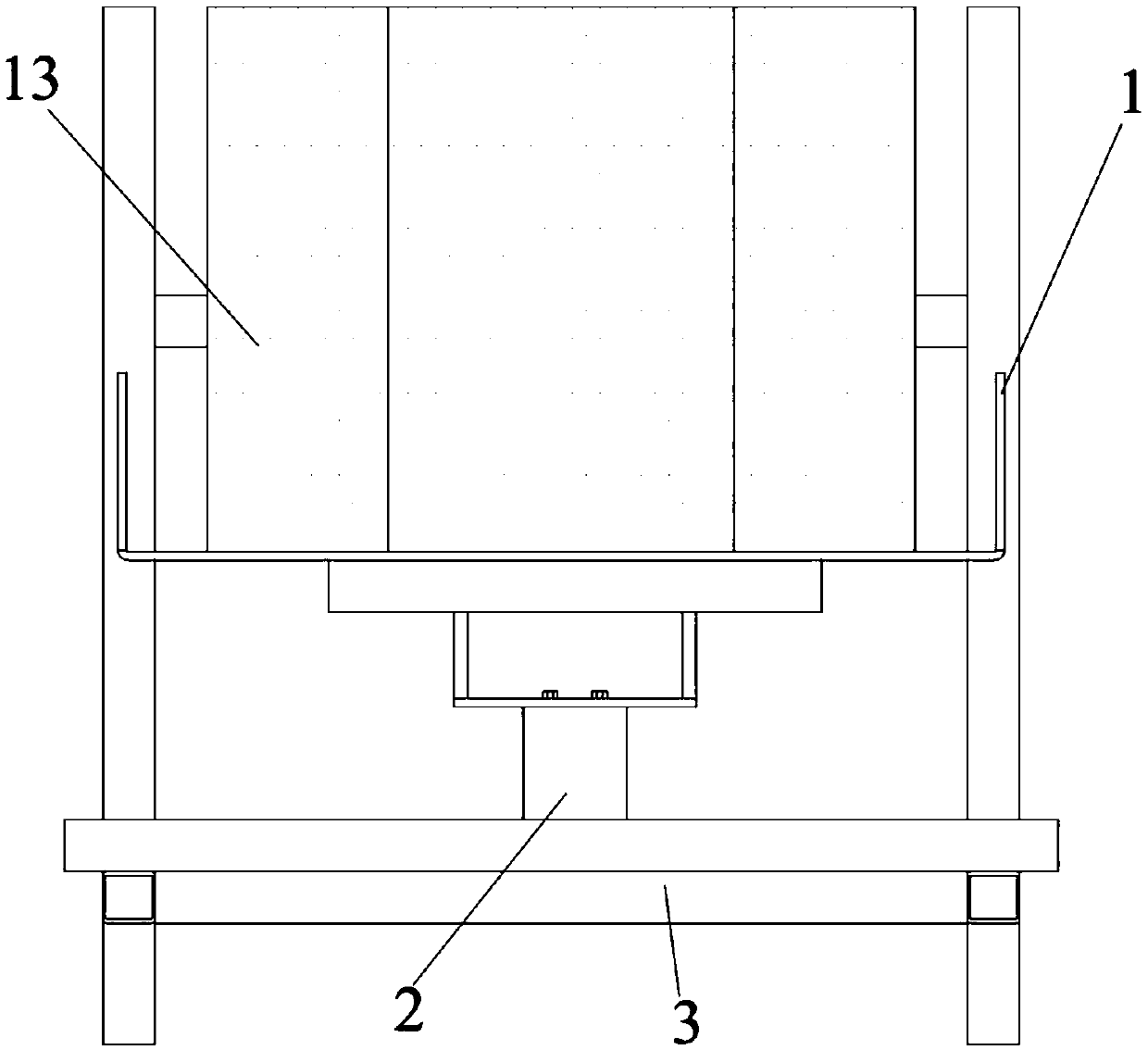

[0024] Embodiment 1: as Figure 1 to Figure 3 As shown, a square baler production measurement system based on Beidou / GPS technology includes a weighing device 11, a first slave controller 4, a Beidou / GPS receiver 5, a second slave controller 7, and a master controller 8. Terminal display 6; said weighing device 11 and the first slave controller 4 are located at the end of the bale output chute 12, and the weighing device 11 includes a weighing tank 1, a load cell 2, and a support frame 3, wherein the weighing Groove 1 is lower than bale output chute 12, the distance is about 200mm, and it is in the shape of two steps; the length of square bale is less than the length of weighing trough 1, and greater than half of the length of weighing trough 1, so as to ensure that the weighing trough Only one square bale is weighed this time; the Beidou / GPS receiver 5 is located outside the tractor 10, and the second slave controller 7, master controller 8, and terminal display 6 are located...

Embodiment 2

[0026] Embodiment 2: the specific process of weighing data reading, when square straw bale falls into weighing groove 1 instant its instantaneous pressure mutation signal is recorded as this square straw bale weighing initial signal I 1 , when the square bale slides out of the weighing slot 1, its instantaneous pressure mutation signal is recorded as the final signal I of this square bale weighing 2 , wherein the first slave controller 4 reads the square bale weighing initial signal I 1 To square bale weighing final signal I 2Between the weighing sensor 2 data, measure 3 sets of weighing data, each set of 30 weighing values, use the Grubbs algorithm to remove the weighing abnormal value in each set of data, and calculate the abnormal value of each set of data After the value has been eliminated, the average value of the data is recorded as the data of this group of weighing, and the average value of the calculation of 3 groups of weighing data is recorded as the final data of...

Embodiment 3

[0032] Embodiment 3: the measurement of working area, Beidou / GPS receiver 5 gathers a latitude and longitude information per second, and the latitude and longitude information is sent to the second slave controller 7, and the second slave controller 7 reads the latitude and longitude of Beidou / GPS receiver 5 Data, the longitude and latitude data are converted into the working distance and combined with the width of the baler 9 to calculate the real-time farmland working area, and the real-time working area is transmitted to the main controller 8 through the CAN bus.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap