Transformer respirator silicone replacement device

A technology of respirator and transformer, applied in transformer/inductor cooling, inductor/transformer/magnet manufacturing, electrical components, etc. Filling on the ground, during the handling process, the silicone cylinder must be vertically upward to avoid problems such as silicone spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

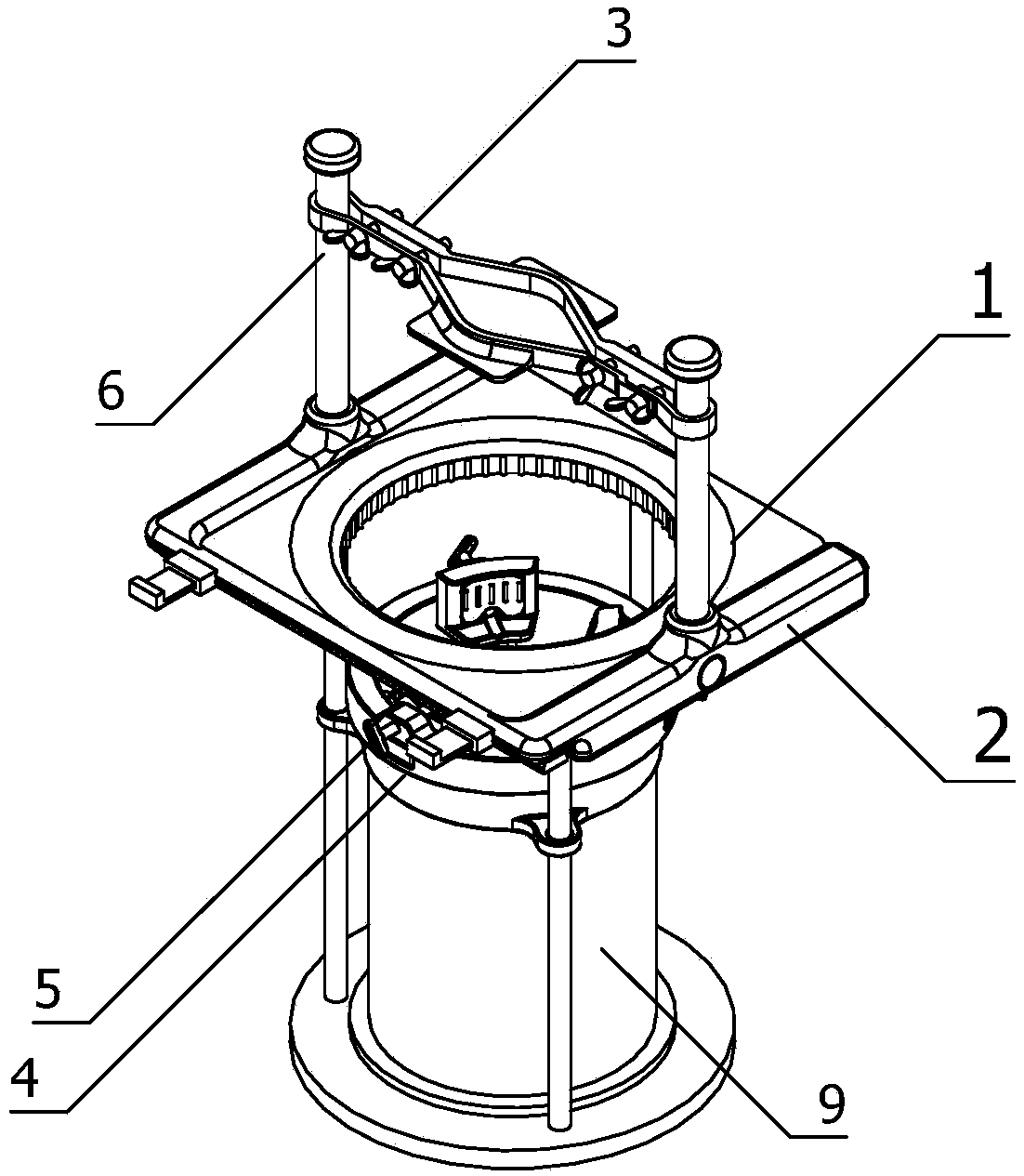

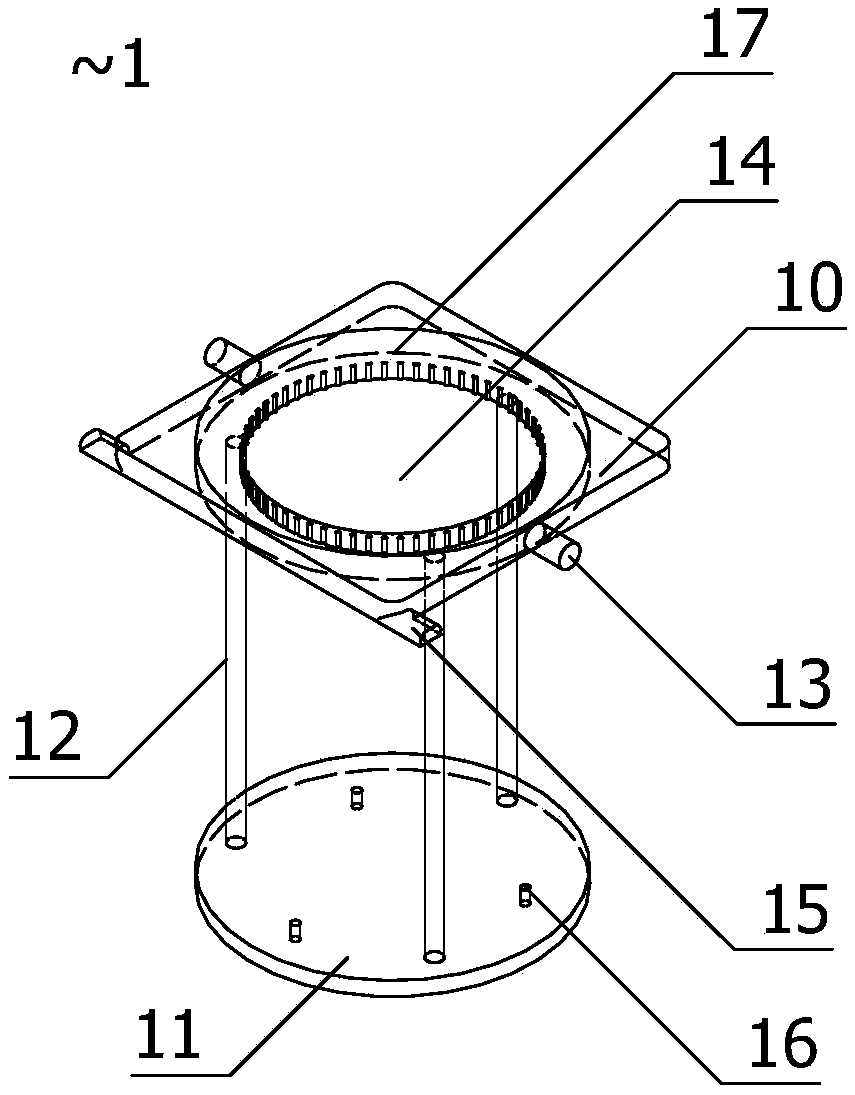

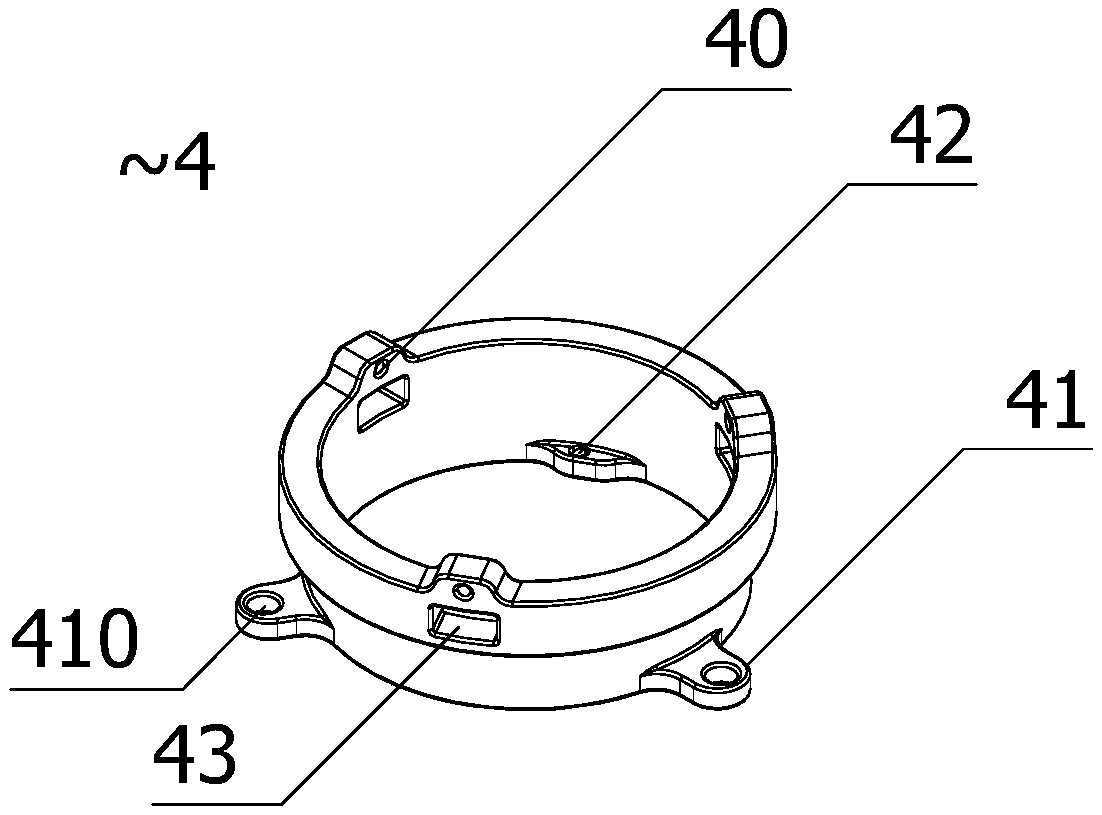

[0028] Such as Figure 1-Figure 7 The silicone replacement device for transformer respirator shown is used for the replacement and maintenance of transformer respirator. The respirator is generally hoisted above a certain height on the ground. In the common process of respirator replacement and maintenance, limited by the operating space, generally The respirator needs to be disassembled and placed on a flat ground for operation. Due to the limitation of the respirator structure, generally at least two operators are required to operate to ensure correct installation and no silicone spills. Therefore, the respirator should be transported during the disassembly process. A large amount of work is required. After analyzing the original structure of the transformer respirator and its installation characteristics, the silica gel replacement device for transformer respirator of the present invention proposes a silica gel replacement operation that only requires one person at the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com