Wiped film evaporator

A wiped film evaporator and evaporation cylinder technology, applied in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of uneven heating and easy drying of wiped film evaporators, and improve evaporation efficiency and production capacity. Uniform distribution of materials and the effect of preventing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

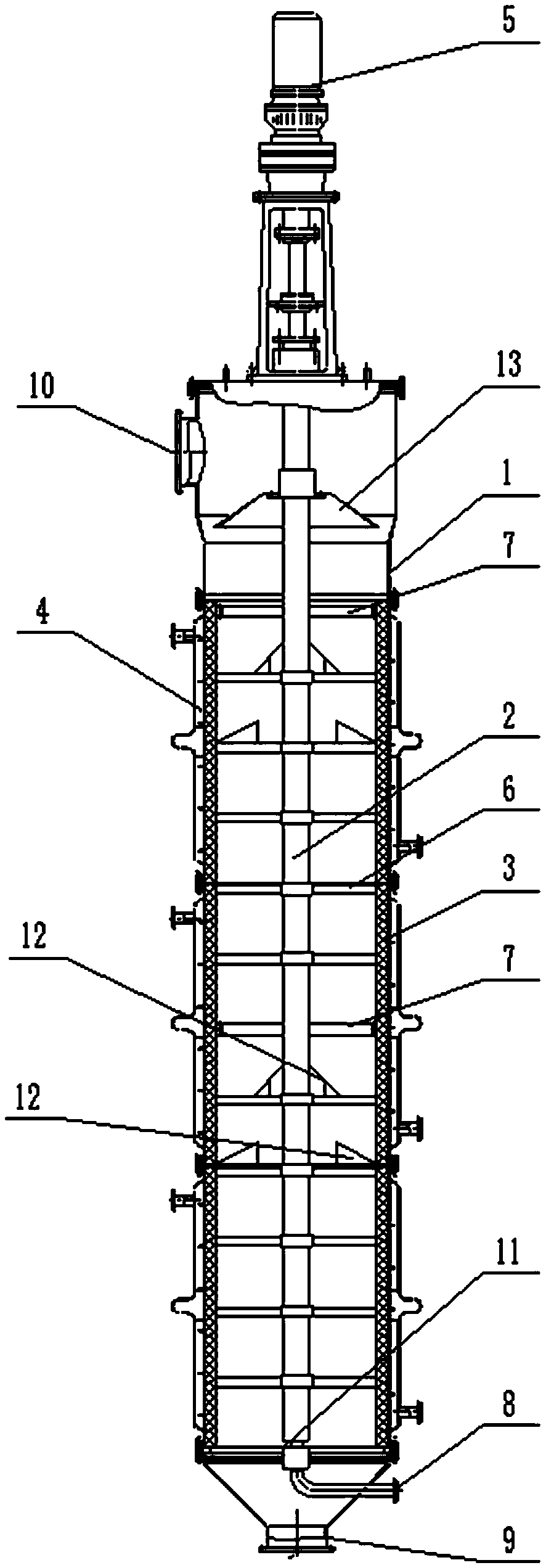

[0027] Such as figure 1 As shown, a wiped film evaporator includes an evaporation cylinder 1 , a drive shaft 2 and a scraper 3 . The evaporation cylinder 1 has a plurality of heat medium jackets 4 sequentially from top to bottom. The transmission shaft 2 is driven to rotate by the motor 5 and is arranged in the evaporation cylinder 1 . The scraper 3 is connected to the transmission shaft 2 through a plurality of scraper supports 6 . Two feed distributors 7 are arranged on the transmission shaft 2, and the transmission shaft 2 and the two feed distributors 7 arranged at intervals are hollow and communicate with each other. The materials pass through the cavity of the transmission shaft 2 and the feed distributor 7, Spray from one end of the feed distributor 7 to the inner wall of the evaporation cylinder 1 . Both the material inlet 8 and the material outlet 9 are located at the lower part of the evaporation cylinder 1 , and the upper part of the evaporation cylinder 1 has a ...

Embodiment 2

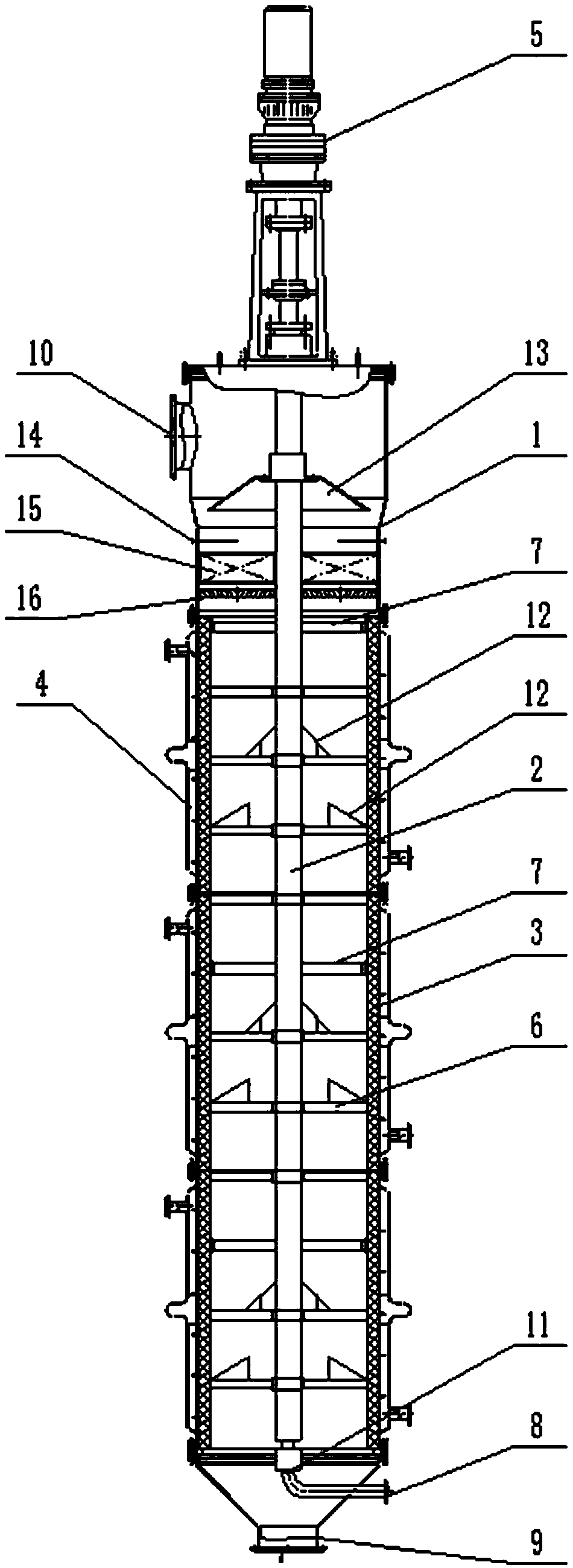

[0029] Such as figure 2 As shown, a wiped film evaporator includes an evaporation cylinder 1 , a drive shaft 2 and a scraper 3 . The evaporation cylinder 1 has a plurality of heat medium jackets 4 sequentially from top to bottom. The transmission shaft 2 is driven to rotate by the motor 2 and is arranged in the evaporation cylinder 1 . The scraper 3 is connected to the transmission shaft 2 through a plurality of scraper supports 6 . Three feed distributors 7 are arranged on the transmission shaft 2, the transmission shaft 2 and the three feed distributors 7 arranged at intervals are hollow and communicate with each other, and the materials pass through the cavity of the transmission shaft 2 and the feed distributor 7, One end of the feed distributor 7 is sprayed toward the inner wall of the evaporation cylinder 1 . Both the material inlet 8 and the material outlet 9 are located at the lower part of the evaporation cylinder 1 , and the upper part of the evaporation cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com