Safety bench saw protecting saw blade

A table saw and saw blade technology, which is applied in the field of safety table saws, can solve the problems of teeth collision and damage, cutting hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

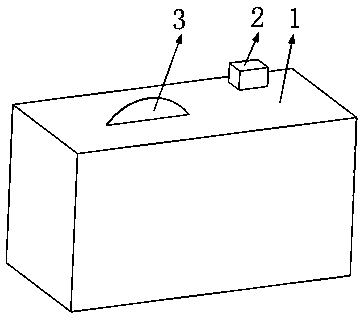

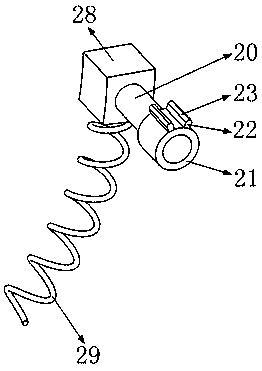

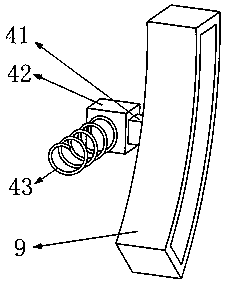

[0085] Specific embodiments: when the table saw works normally, the trigger powder in the powder chamber 35 has not exploded, and the telescopic rod 12 is perpendicular to the first swing rod 8; the first swing rod 8 and the second swing rod 31 are collinear. The first limiting tooth 22 and the second limiting tooth 24 have no limiting effect. The leaf spring 56 is in a compressed state, the fourth limiting tooth 58 is located in the gap between two adjacent third limiting teeth 51, the third limiting tooth 51 and the fourth limiting tooth 58 produce a limiting effect, and the fourth limiting tooth 58 produces a limiting effect. The second pendulum plate 57 and the fifth U-shaped plate 55 are limited so that the slider 52 cannot slide in the sliding groove 49 . The motor 5 drives the driven wheel 16 to rotate through the drive shaft 14, the drive wheel 6 and the belt 15; the driven wheel 16 drives the ring saw blade 3 to rotate through the drive ring 25 and the ring sleeve 17....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com