Grinding equipment for right-angle double-head clamps

A double-headed, right-angle technology, used in grinding/polishing equipment, grinding slides, grinding racks, etc., can solve problems such as difficulty in processing right-angle double-headed clamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

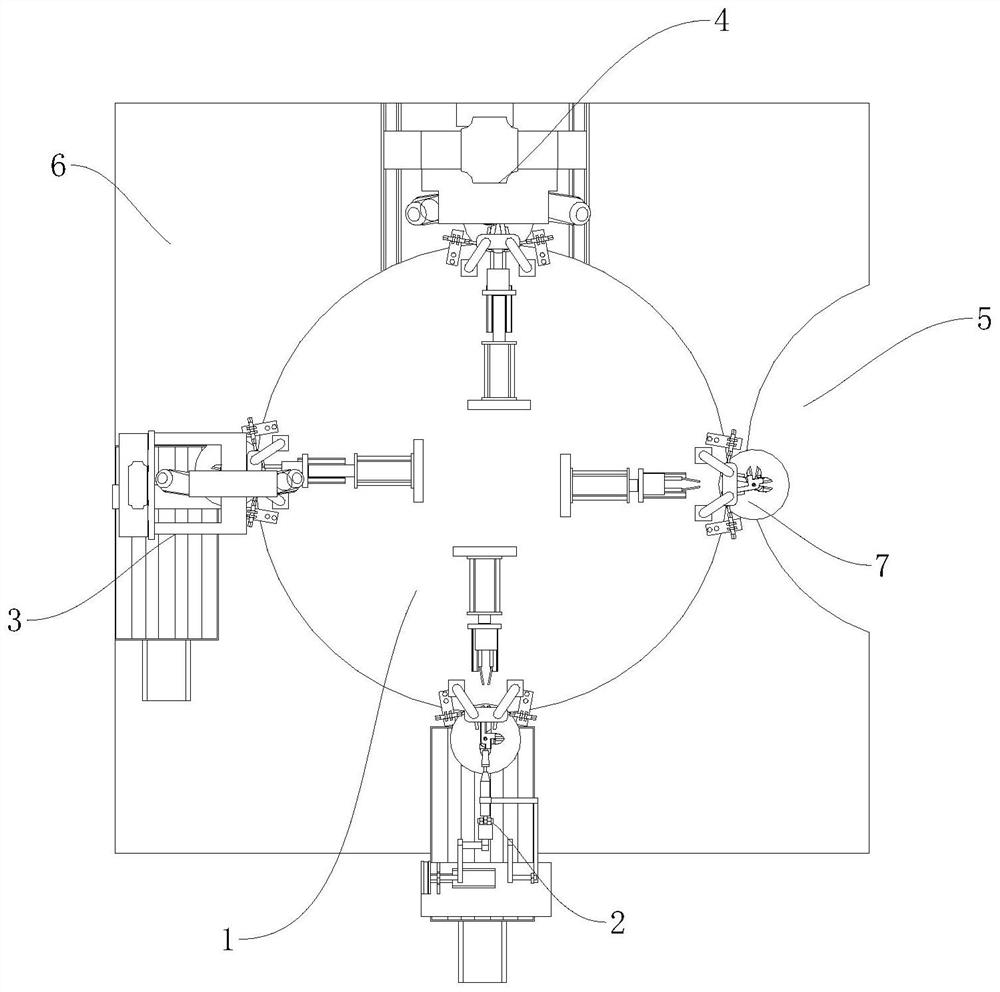

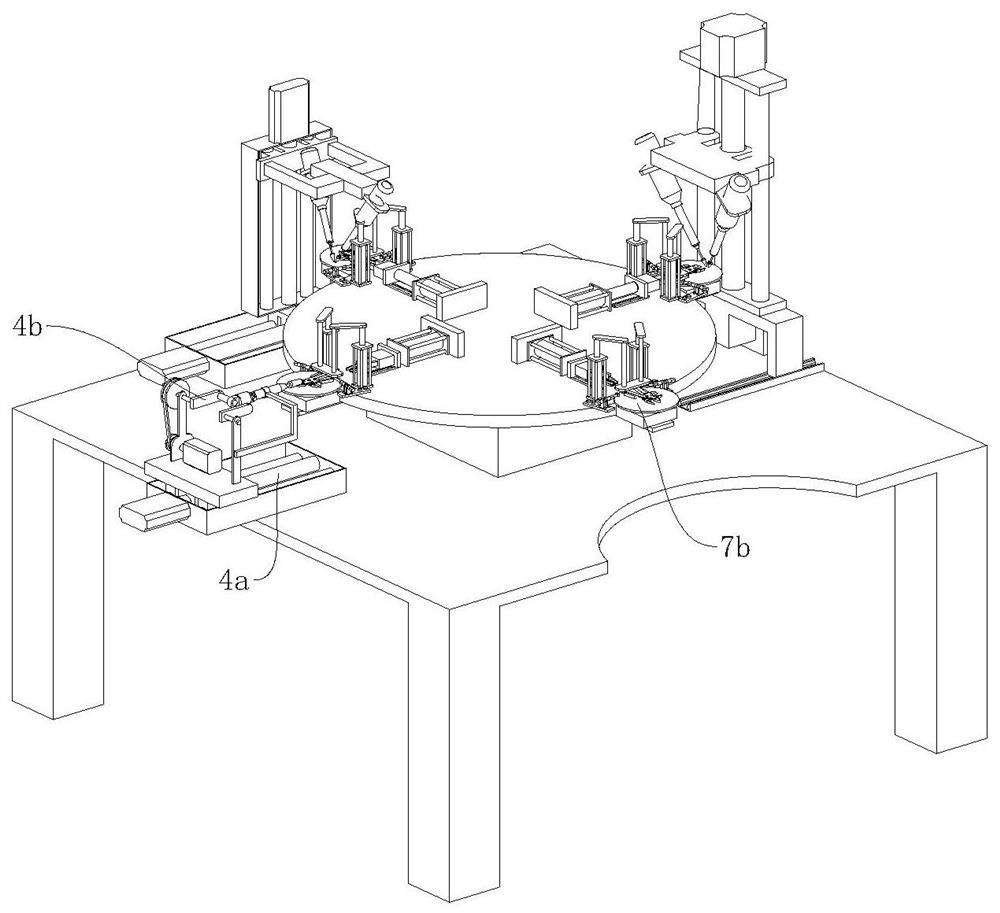

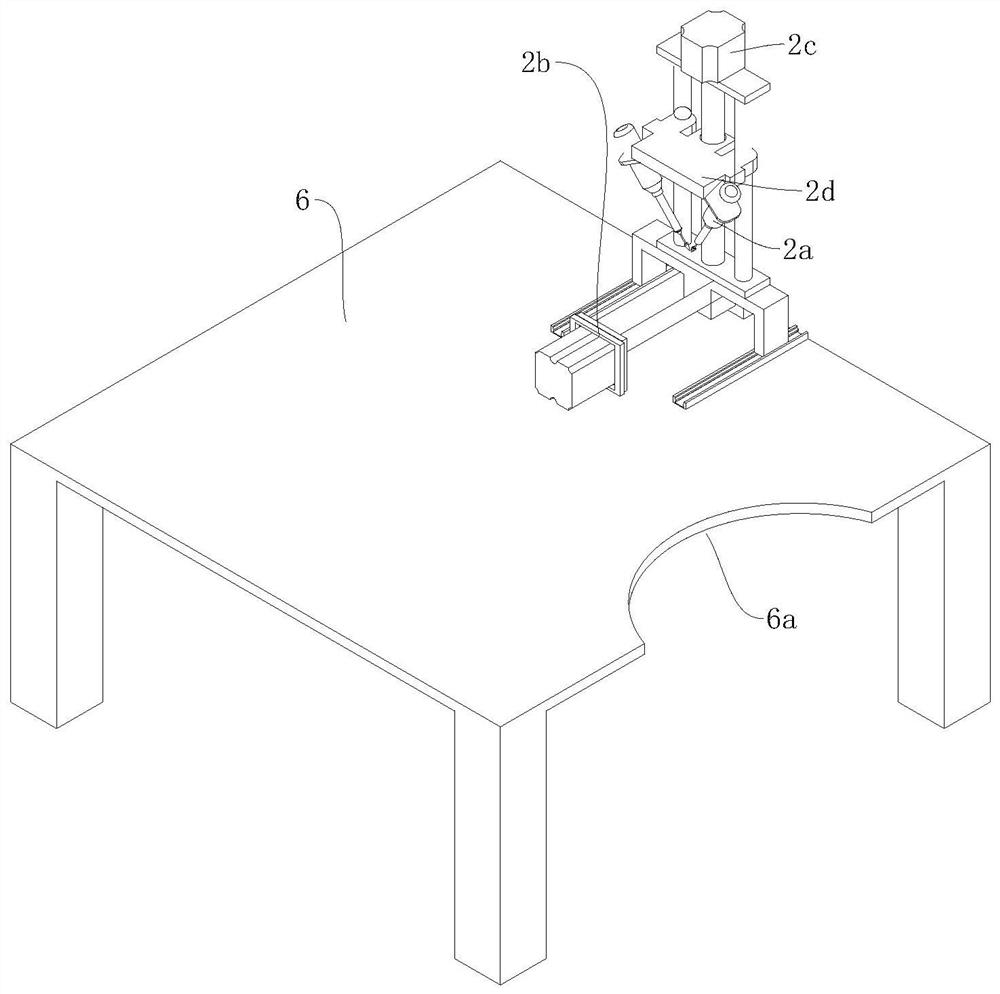

[0033] refer to Figure 1 to Figure 10 The grinding equipment for a right-angled double-headed clamp includes a base 6, a rotary table 1, a first jaw rough grinding station 2, a second jaw rough grinding station 3, a fine grinding Station 4 and material handling station 5, the rotary table 1 includes a first indexing plate 1a and a first rotating disc 1b, the first indexing plate 1a is fixedly arranged on the base 6 and the first indexing plate 1a The output end of the dial 1a is set upwards, and the first rotating disc 1b is set on the first indexing disc 1a in a horizontal state. The first rotating disc 1b is also provided with four right-angle double-head clamps 8 for fixing The workpiece fixture 7, the first jaw rough grinding station 2, the second jaw rough grinding station 3, the fine grinding station 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com