Bucket grabbing tool

A gripper and lower seat technology, applied in the field of barrel grippers, can solve the problems of inconvenient handling of radioactive solid waste and radioactive waste liquid cement solidified barrels, and the inability of barrel grippers to meet the use requirements, etc., to achieve simple structure, accurate engagement and decoupling , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the drawings and specific implementations of the specification.

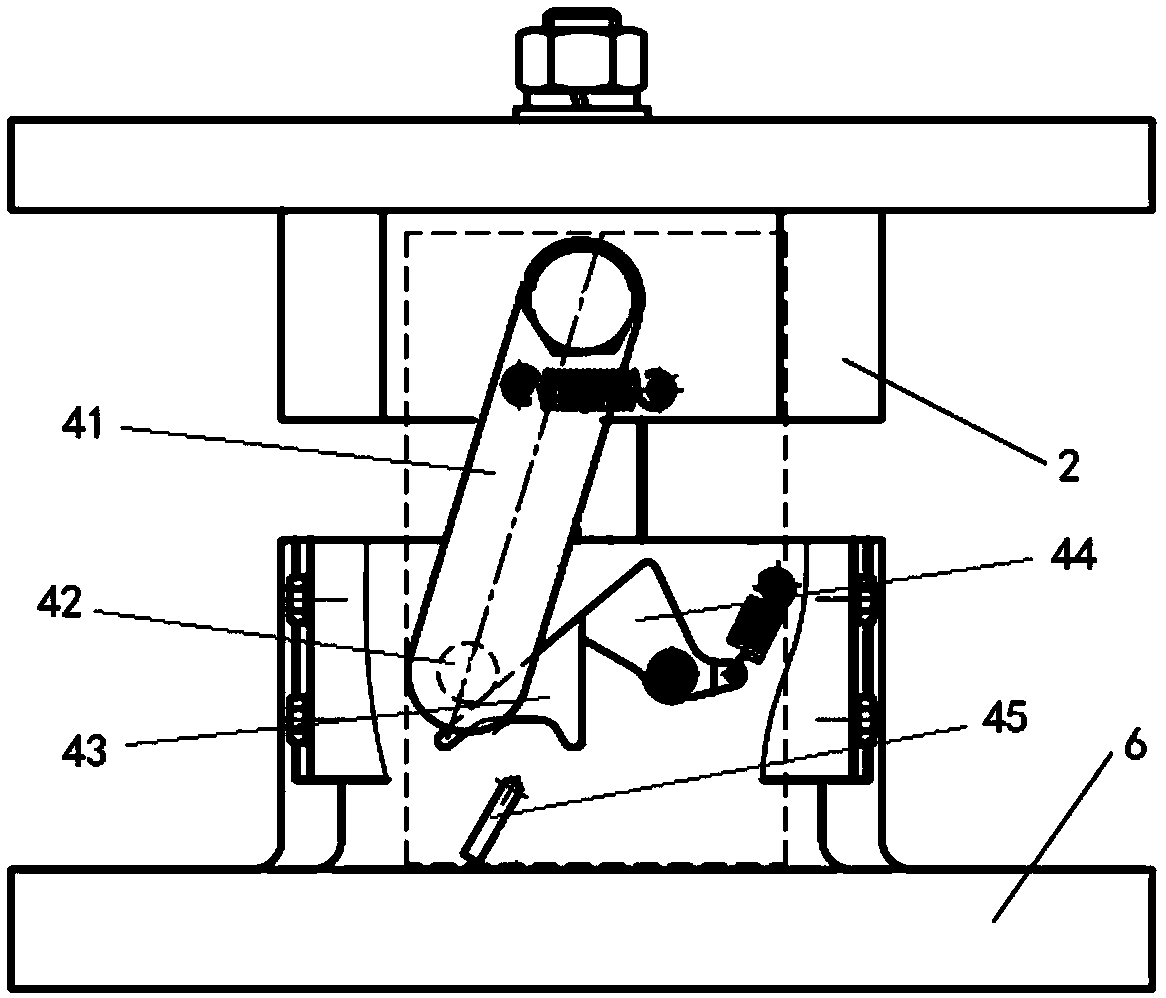

[0049] The invention is specifically designed for 200L waste barrels containing radioactive waste. According to the requirements of radioactive sites, the non-powered self-locking mechanism 4 and the positioning mechanism 5 of the gripper are designed and verified, and the requirements in actual applications are A variety of lifting methods are designed, including single hook lifting, two-wheeled wire rope lifting, and two-wheeled lifting of rotatable grabs. It solves the problems of the gripper rotating and swinging in the lifting process in the application and the requirements of the gripper rotating in the application.

[0050] According to an embodiment of the present invention:

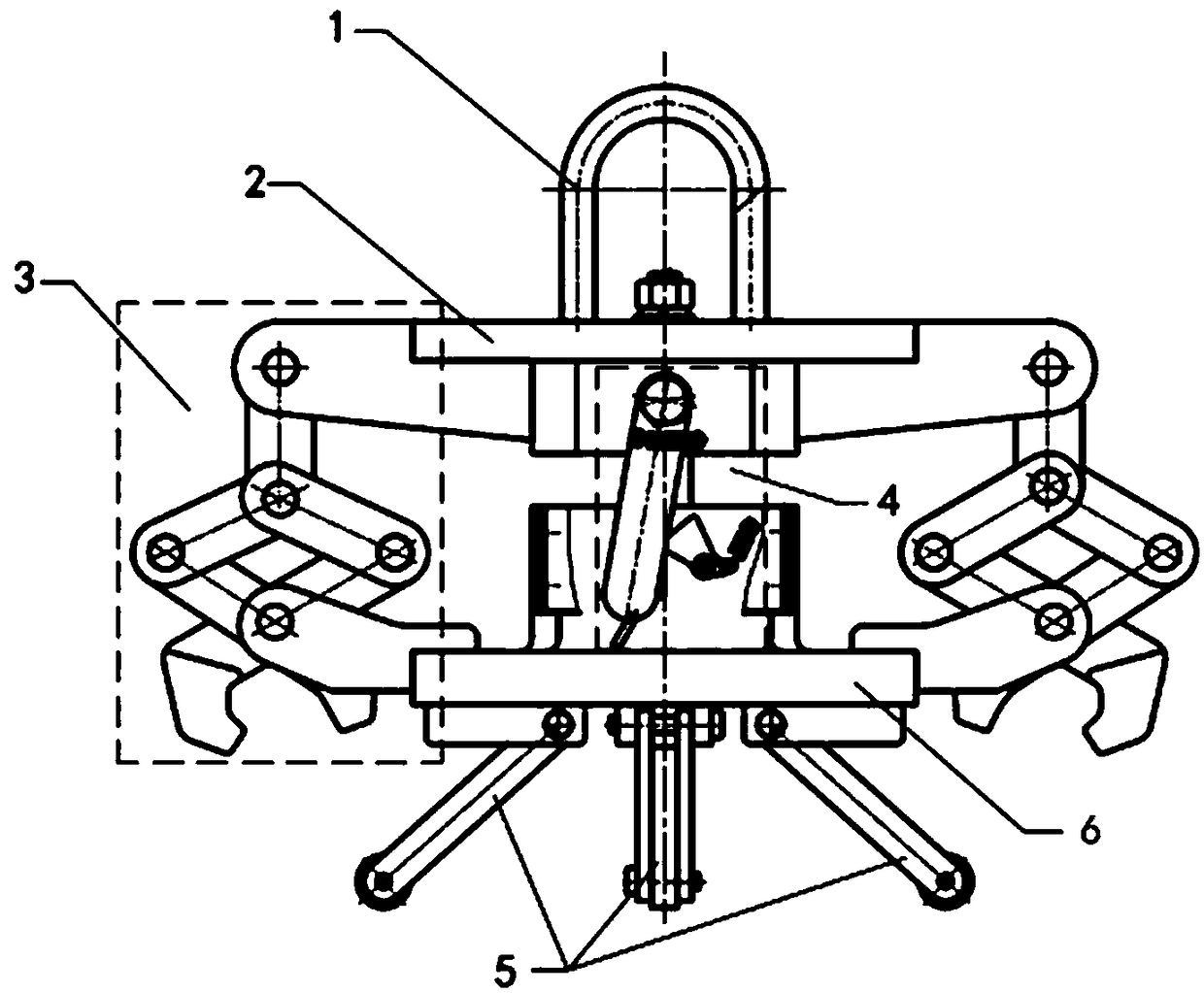

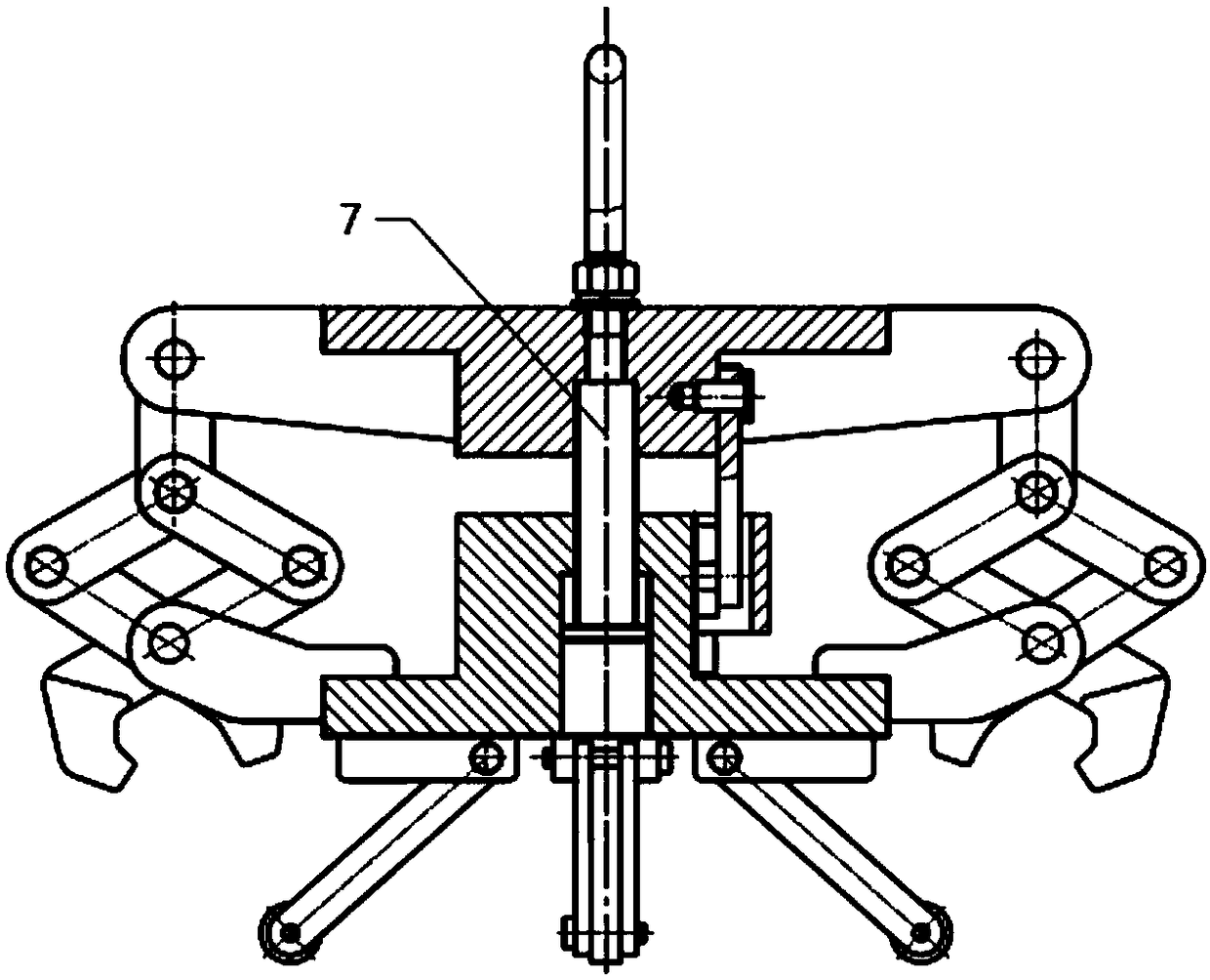

[0051] The structural schematic diagram of the bucket gripper of the embodiment of the present invention is as figure 1 As shown, it includes a lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com