Silane/graphene oxide composite passivation solution and its preparation method and application

A graphene composite and passivation solution technology, which is applied in the coating process of metal materials, etc., can solve the problems of inability to achieve protective effects, difficult processing and molding, poor bonding, etc., achieve excellent anti-corrosion effects, easy to operate, and easy to prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the silane / graphene oxide composite passivation solution of an embodiment of the present invention comprises the following steps:

[0038] Mix the water-based silane coupling agent, water and alcohol in a volume ratio of 1:(7-9):(0.8-1.2) to obtain a mixed solution;

[0039] Add graphene oxide to the mixed solution, and ultrasonically treat it to obtain a dispersion;

[0040] Adjust the pH of the dispersion to a pH of 2-4, and perform hydrolysis to obtain a silane / graphene oxide composite passivation solution.

[0041] The preparation method of the above-mentioned silane / graphene oxide composite passivation solution combines the advantages of both graphene oxide and silane, utilizes the co-hydrolysis of graphene oxide and water-based silane coupling agent to realize the silane functionalization of graphene oxide, silane coupling Covalent bonds can be formed between the agent and the metal substrate, which is conducive to improving the bonding ...

Embodiment 1

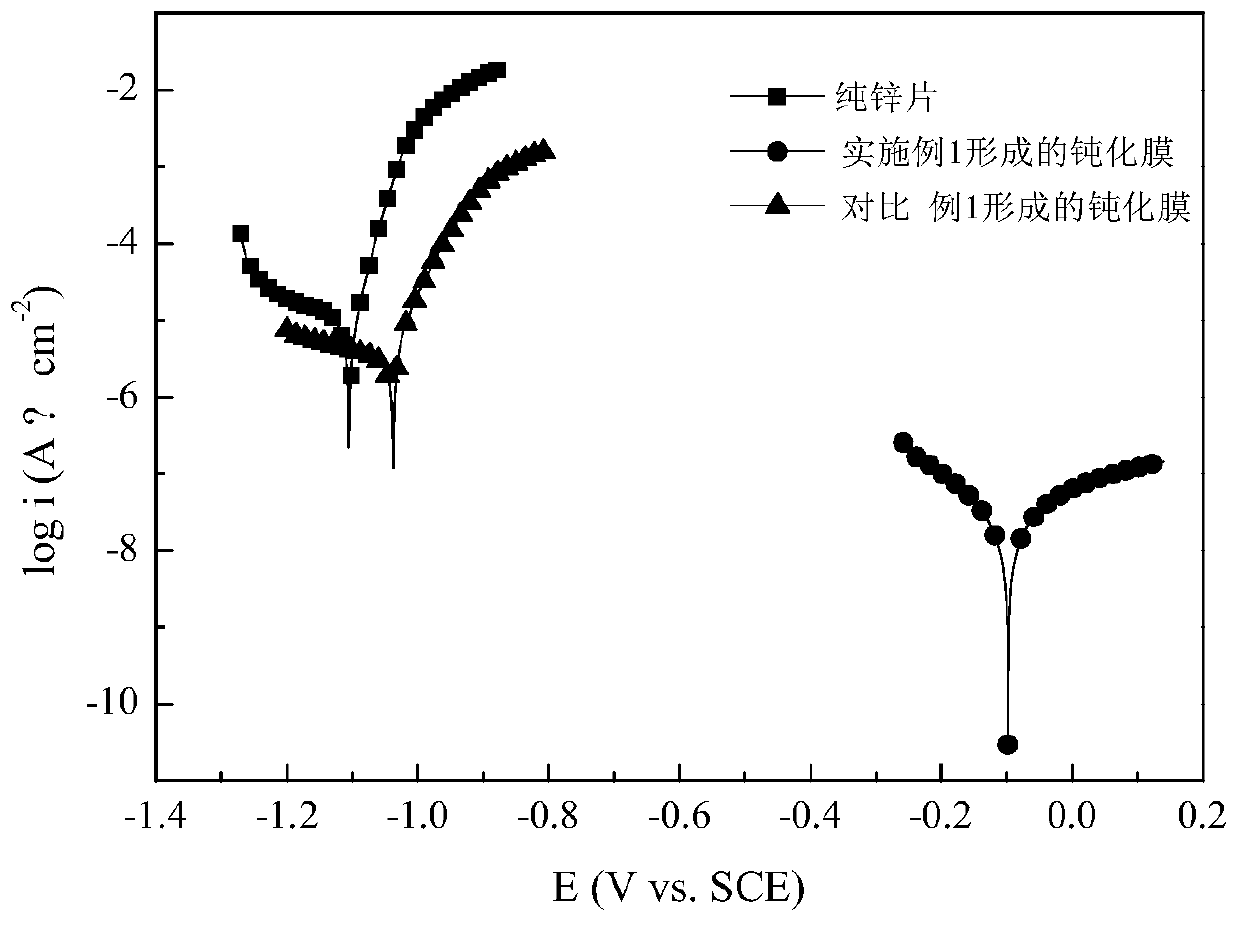

[0060] This embodiment provides a method for carrying out anti-corrosion treatment on the surface of the zinc flake, and the specific test process is as follows:

[0061] In a 200ml beaker, first add 10ml of absolute ethanol, then add 80ml of deionized water, then add 10ml of KH560 silane coupling agent, and stir well. Slowly add 50mg of graphene oxide, stir while adding, and then sonicate for 20min. Then add acetic acid to adjust the pH value to 3.3, stir evenly, seal and let it stand, and hydrolyze for 24 hours to obtain a passivation solution.

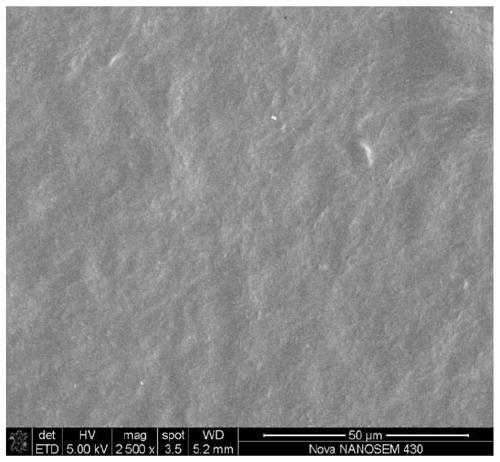

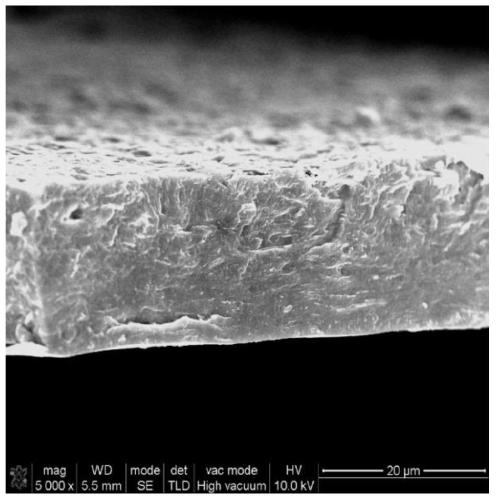

[0062] Grind the surface of the zinc sheet with metallographic sandpaper, polish it with a metallographic polishing machine, then ultrasonically wash it with distilled water, then wash it with absolute ethanol and deionized water in sequence, and after drying, immerse it in the above passivation solution at 20°C for 1 hour. , and then dried at 60°C for 6 hours, and cooled naturally to cover a layer of silane / graphene oxide composit...

Embodiment 2

[0064] This embodiment provides a method for carrying out anti-corrosion treatment on the surface of the zinc flake, and the specific test process is as follows:

[0065] In a 200ml beaker, first add 10ml of absolute ethanol, then add 80ml of deionized water, then add 10ml of KH560 silane coupling agent, and stir well. Then slowly add 80 mg graphene oxide, stir while adding, and then sonicate for 30 minutes. Then add acetic acid to adjust the pH value to 3.3, stir evenly, seal and let it stand, and hydrolyze for 24 hours to obtain a passivation solution.

[0066] Grind the surface of the zinc sheet with metallographic sandpaper, polish it with a metallographic polishing machine, then ultrasonically wash it with distilled water, then wash it with absolute ethanol and deionized water in turn, and immerse it in the above passivation solution for 2 hours at 20°C after drying. , and then dried at 180°C for 3 hours, and cooled naturally to cover a layer of silane / graphene oxide com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com