Novel water level sensor and washing machine

A water level sensor and a new type of technology, applied in the field of washing machines, can solve problems such as poor terminal contact, washing machine dehydration with water, affecting output frequency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

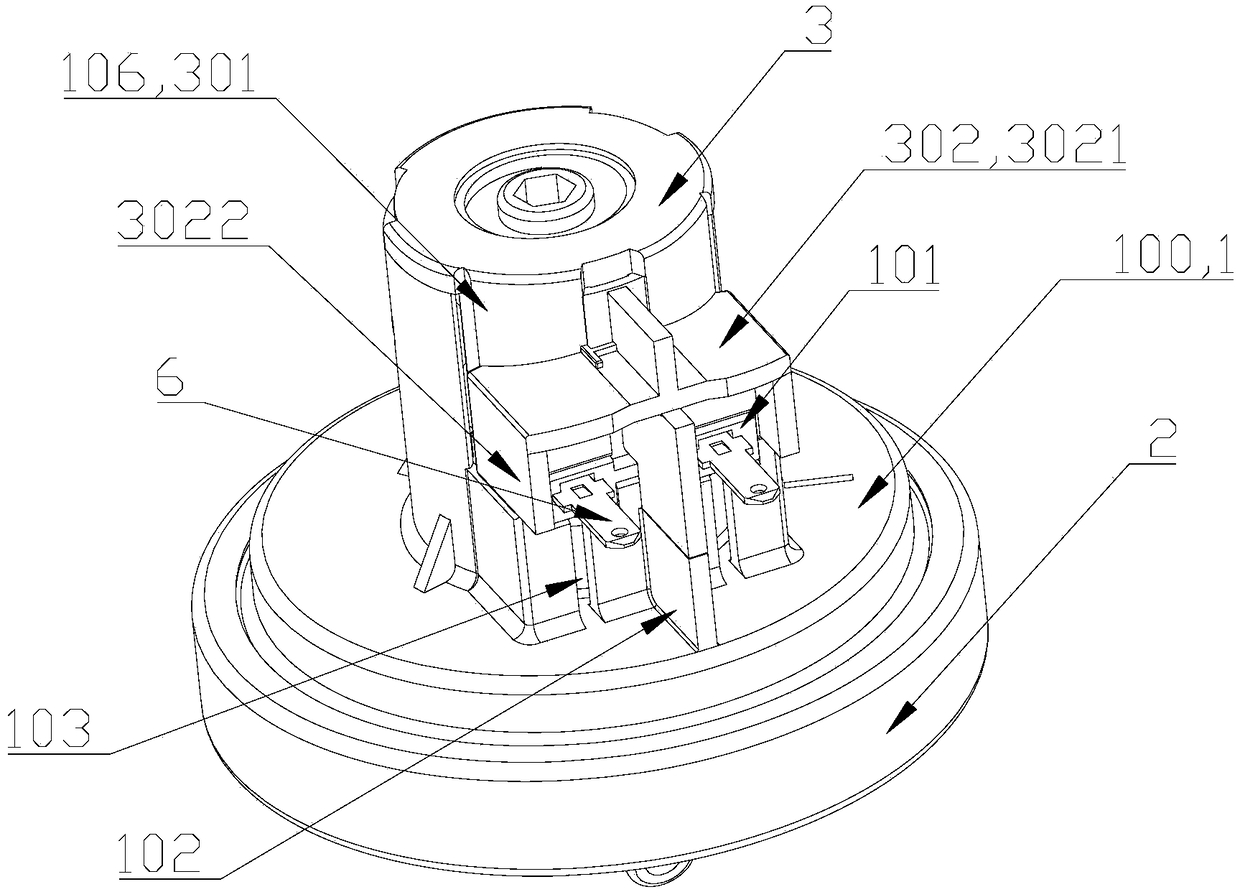

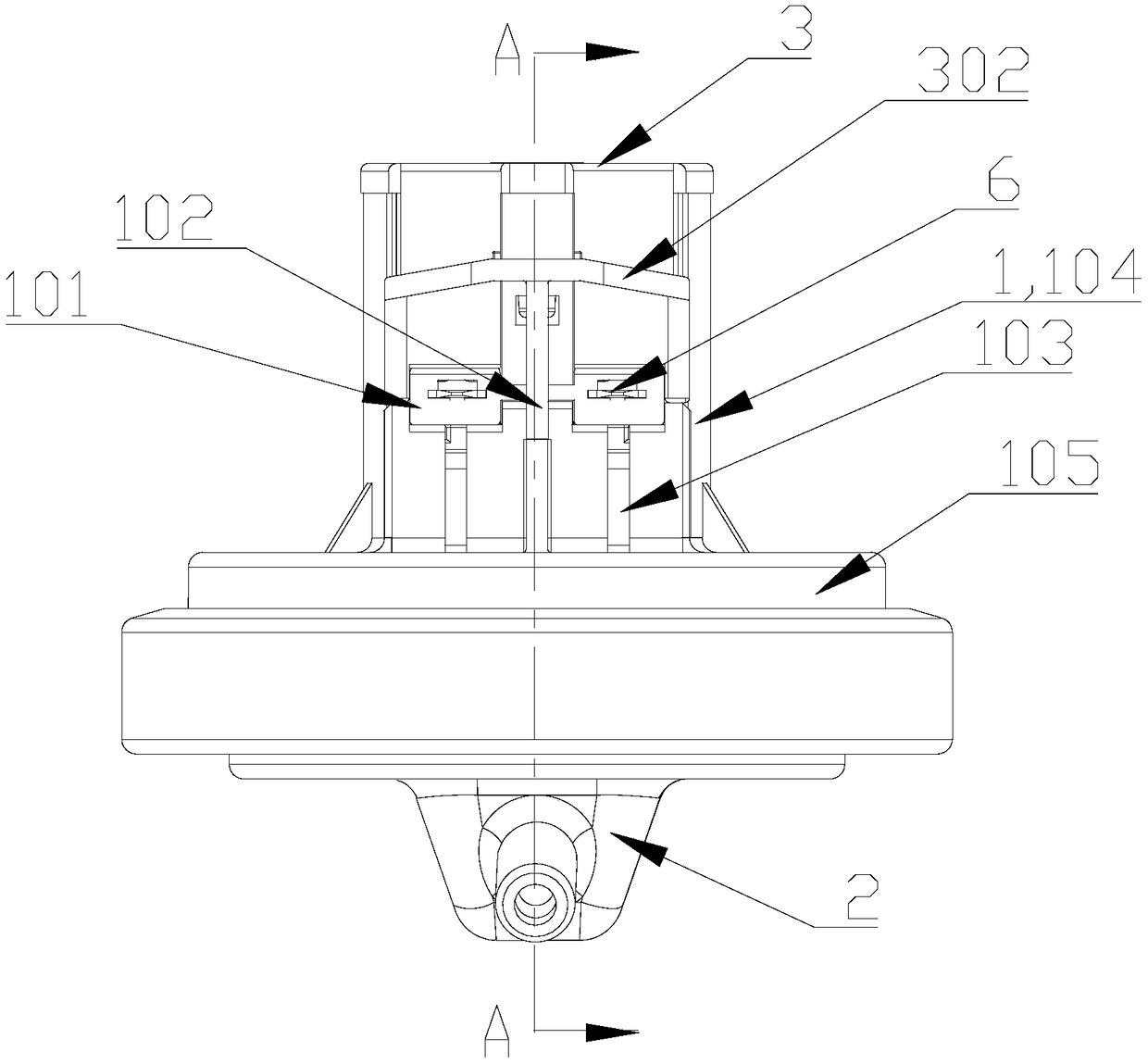

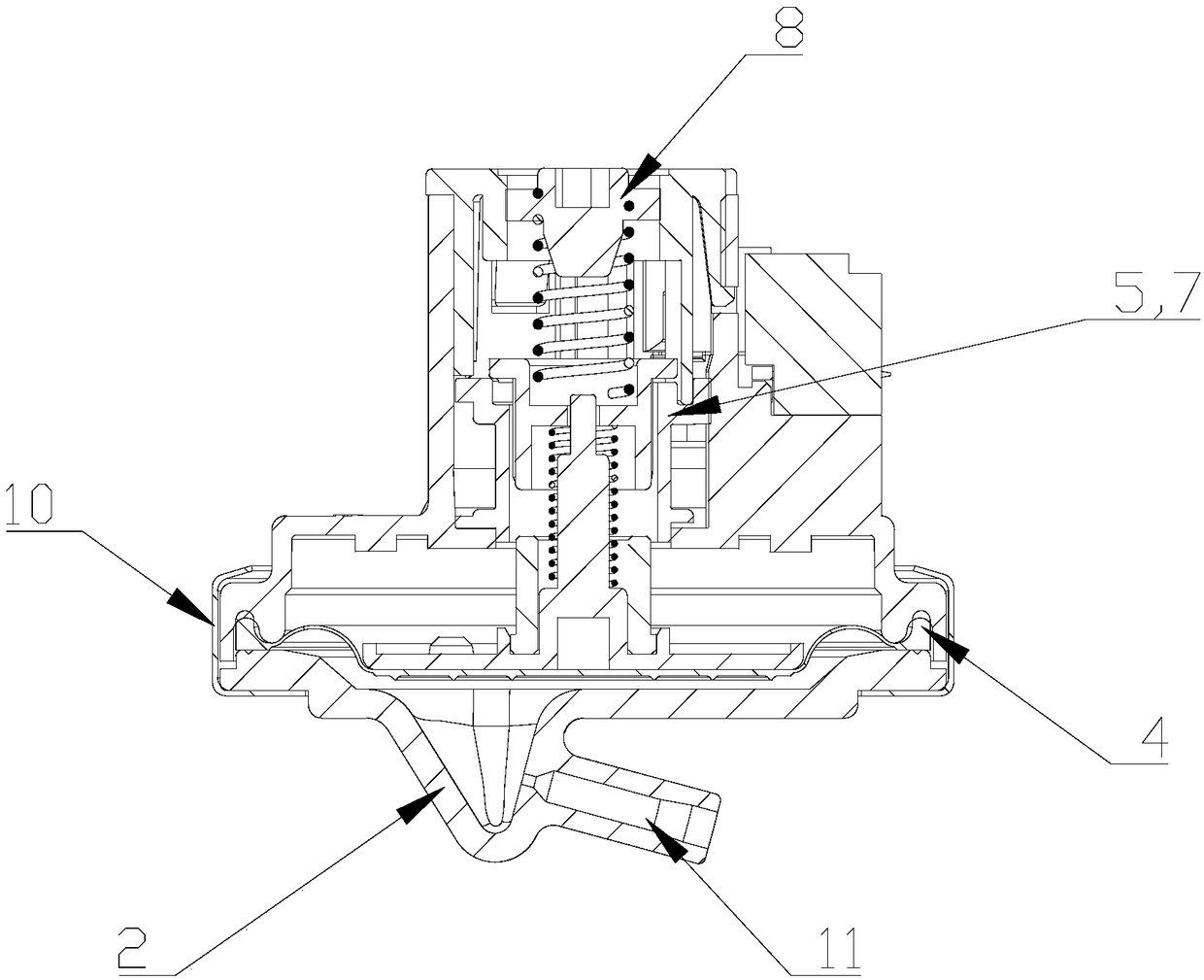

[0036] like Figure 1 to Figure 4 As shown, a new type of water level sensor 100 is introduced in this embodiment, which includes a housing 1, an air cover 2, an adjusting screw receiving plate 3, and a rubber diaphragm 4 is installed in the chamber surrounded by the housing 1 and the air cover 2, and the rubber diaphragm 4 Divide the chamber into upper and lower chambers, the lower chamber is the air intake cavity, which communicates with the air intake nozzle 11 provided on the gas cover 2; the upper chamber is equipped with a coil unit, and the coil unit It includes a coil shaft 5 , an inductance coil 7 and at least two terminals 6 .

[0037]In this embodiment, the bottom of the gas cover 2 and the housing 1 is fixedly connected by a riveting ring 10, and a rubber diaphragm 4 is installed in the chamber surrounded by the gas cover 2 and the housing 1, and one side of the rubber diaphragm 4 is connected to the intake air. The other side of the diaphragm is connected to the ...

Embodiment 2

[0040] like Figure 1 to Figure 4 As shown, a new type of water level sensor 100 is introduced in this embodiment, which includes a housing 1, an air cover 2, and an adjusting screw receiving plate 3. A coil unit is installed in the chamber surrounded by the housing 1 and the air cover 2, and the coil unit includes The coil shaft 5, the inductance coil 7 and at least two terminals 6; the housing 1 is provided with an insertion interface 101, and the terminals 6 protrude from the insertion interface 101 of the housing 1, and are all fixed on the same side of the housing 1, and the housing 1 A baffle 102 located in the middle of adjacent terminals 6 is provided on the outer wall to separate adjacent terminals 6 , so as to ensure mutual insulation between adjacent terminals 6 and avoid short circuit of terminals 6 caused by dew condensation on housing 1 .

[0041] In this embodiment, the sockets 101 are arranged adjacent to each other in parallel and at the same height. The termi...

Embodiment 3

[0043] like Figure 1 to Figure 4 As shown, in this embodiment, the outer wall of the housing 1 is provided with a protective cover 302 located above the terminal 6, and the protective cover 302 is placed horizontally, parallel to the terminal, and extends outward. Condensation formed on the casing 1 due to high humidity will gather on the protective cover 302 , and under the action of gravity, the condensation will flow to the base 105 of the casing 1 . By setting the protective cover 302, the condensation generated by the housing 1 above the terminal 6 will not gather on the terminal 6, avoiding the copper green phenomenon of the terminal 6 affected by the humid environment, thereby avoiding the occurrence of poor contact of the terminal 6 , further avoiding the washing machine with an empty bucket or dehydration with water.

[0044] In this embodiment, the top of the housing 1 is provided with an opening, and the adjusting screw receiving plate 3 is inserted into the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com