A New Water Level Sensor Applied in Washing Machine

A technology of water level sensor and washing machine, applied in the control device of washing machine, other washing machines, applications, etc., can solve the problems of washing machine with water and dehydration, poor terminal contact, short circuit fault, etc., to avoid washing with empty bucket or with water and dehydration, avoid Effects of poor contact and avoidance of patina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

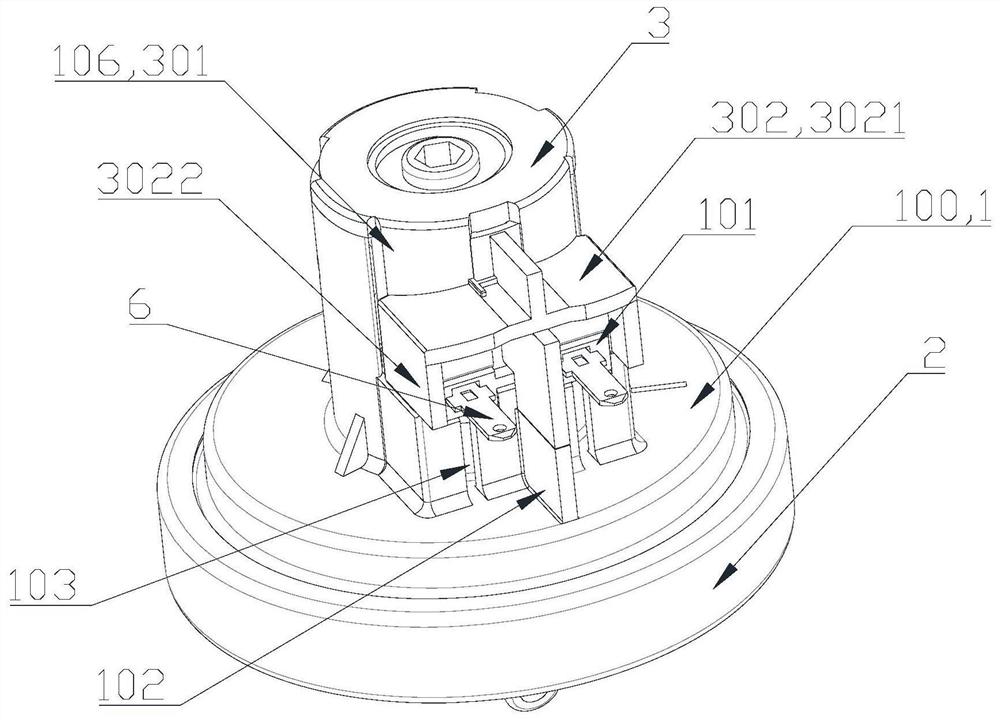

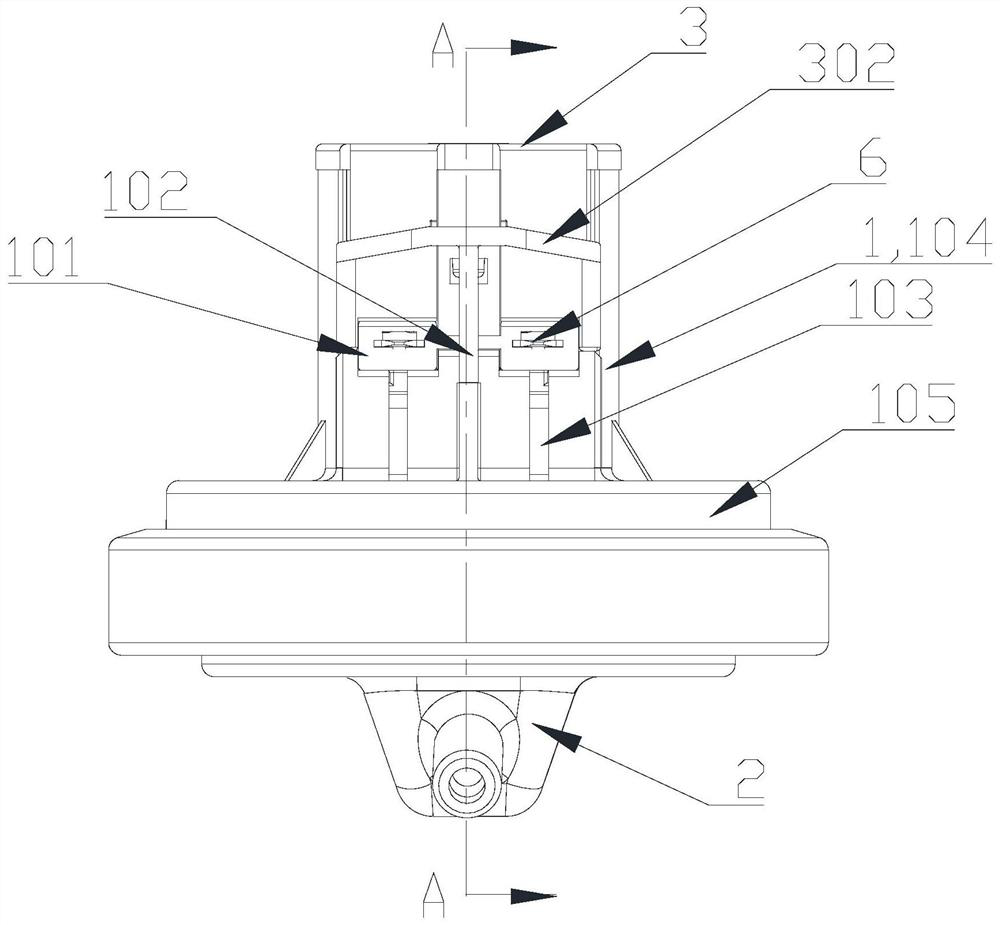

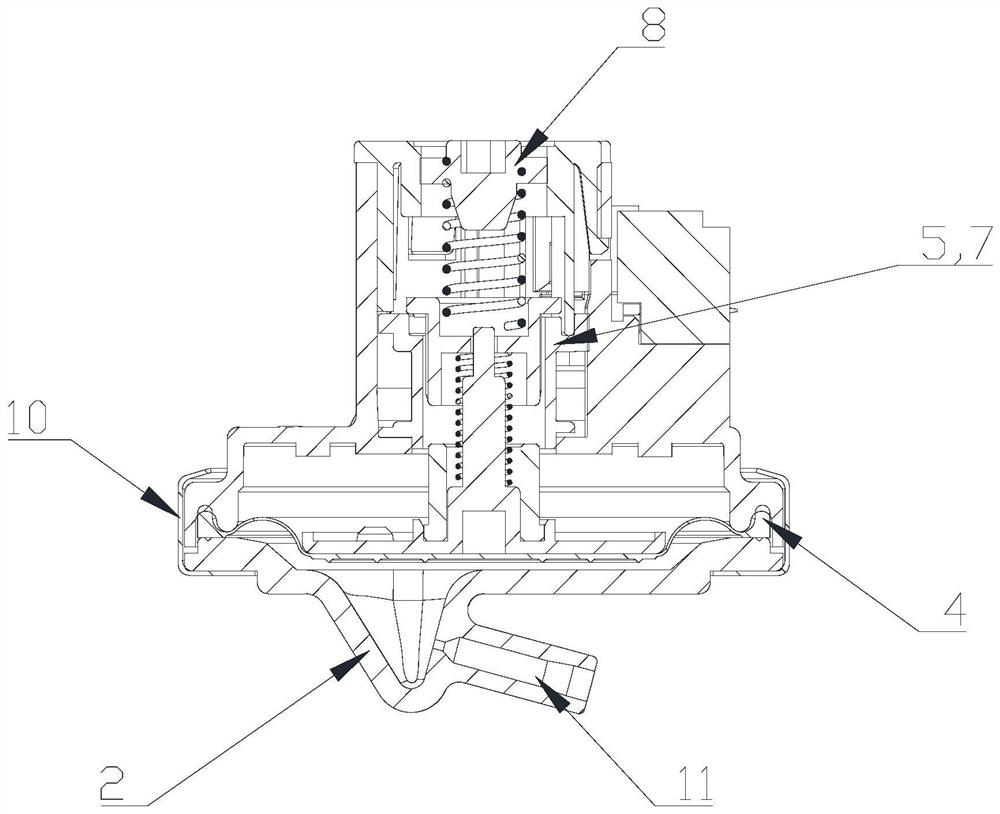

[0036] Such as Figure 1 to Figure 4 As shown, a new type of water level sensor 100 is introduced in this embodiment, which includes a housing 1, an air cover 2, an adjusting screw receiving plate 3, and a rubber diaphragm 4 is installed in the chamber surrounded by the housing 1 and the air cover 2, and the rubber diaphragm 4 Divide the chamber into upper and lower chambers, the lower chamber is the air intake cavity, which communicates with the air intake nozzle 11 provided on the gas cover 2; the upper chamber is equipped with a coil unit, and the coil unit It includes a coil shaft 5 , an inductance coil 7 and at least two terminals 6 .

[0037]In this embodiment, the bottom of the gas cover 2 and the housing 1 is fixedly connected by a riveting ring 10, and a rubber diaphragm 4 is installed in the chamber surrounded by the gas cover 2 and the housing 1, and one side of the rubber diaphragm 4 is connected to the intake air. The other side of the diaphragm is connected to t...

Embodiment 2

[0040] Such as Figure 1 to Figure 4 As shown, a new type of water level sensor 100 is introduced in this embodiment, which includes a housing 1, an air cover 2, and an adjusting screw receiving plate 3. A coil unit is installed in the chamber surrounded by the housing 1 and the air cover 2, and the coil unit includes The coil shaft 5, the inductance coil 7 and at least two terminals 6; the housing 1 is provided with an insertion interface 101, and the terminals 6 protrude from the insertion interface 101 of the housing 1, and are all fixed on the same side of the housing 1, and the housing 1 A baffle 102 located in the middle of adjacent terminals 6 is provided on the outer wall to separate adjacent terminals 6 , so as to ensure mutual insulation between adjacent terminals 6 and avoid short circuit of terminals 6 caused by dew condensation on housing 1 .

[0041] In this embodiment, the sockets 101 are arranged adjacent to each other in parallel and at the same height. The te...

Embodiment 3

[0043] Such as Figure 1 to Figure 4 As shown, in this embodiment, the outer wall of the housing 1 is provided with a protective cover 302 located above the terminal 6, and the protective cover 302 is placed horizontally, parallel to the terminal, and extends outward. Condensation formed on the casing 1 due to high humidity will gather on the protective cover 302 , and under the action of gravity, the condensation will flow to the base 105 of the casing 1 . By setting the protective cover 302, the condensation generated by the housing 1 above the terminal 6 will not gather on the terminal 6, avoiding the copper green phenomenon of the terminal 6 affected by the humid environment, thereby avoiding the occurrence of poor contact of the terminal 6 , further avoiding the washing machine with an empty bucket or dehydration with water.

[0044] In this embodiment, the top of the housing 1 is provided with an opening, and the adjusting screw receiving plate 3 is inserted into the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com