Designing method for basalt fiber porous asphalt mixture matching proportion

A technology of basalt fiber and permeable asphalt, used in roads, road repair, roads, etc., can solve the problems of inaccurate data, large test volume, large randomness, etc., and achieve the effect of improving engineering efficiency, easy operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Step 1. Selection of raw materials and gradation:

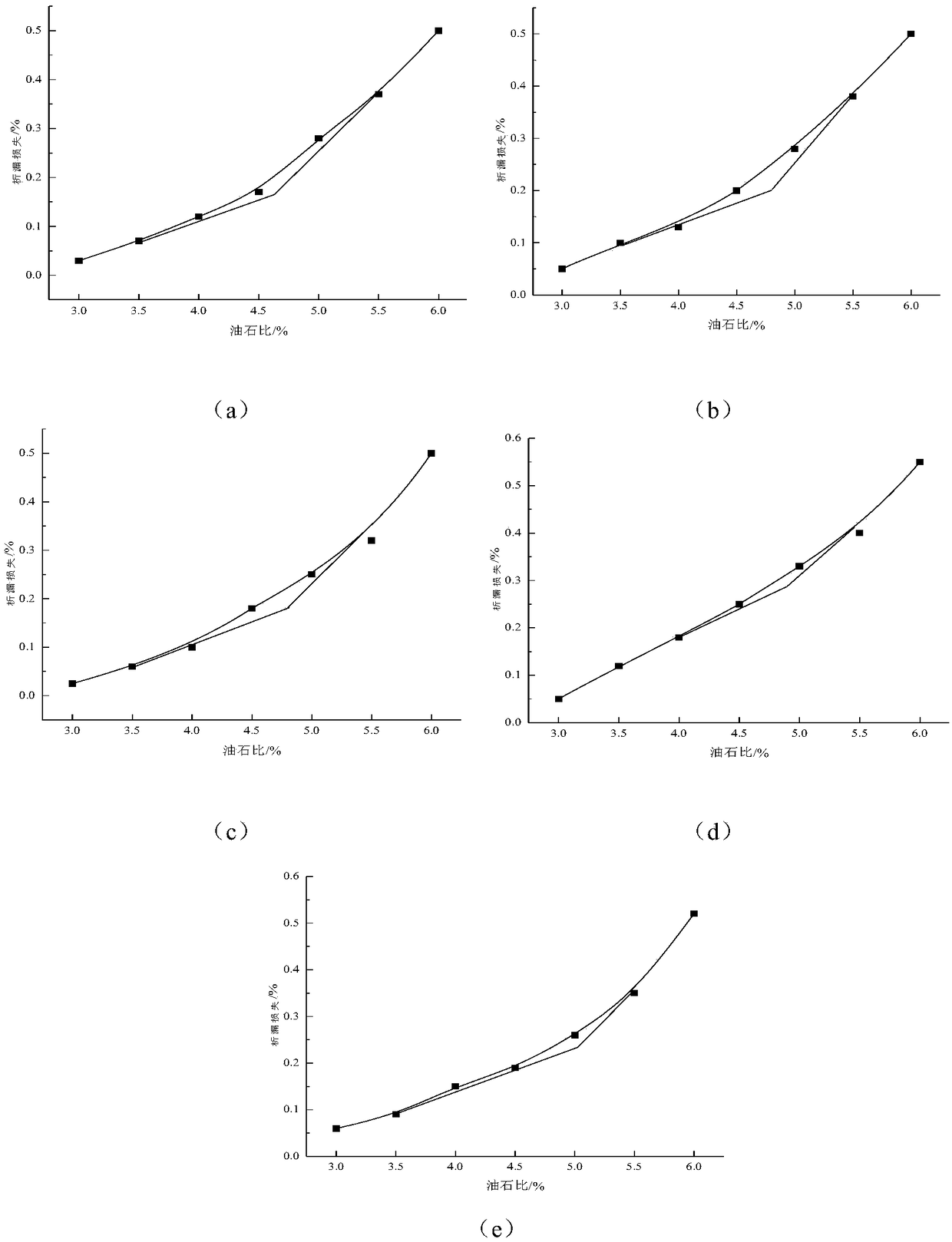

[0035] The gradation design of permeable asphalt mixture PAC-13 is designed with reference to the mineral gradation range specified in CJJ / T 190-2012 "Permeable Asphalt Pavement Technical Specification". The determined synthetic gradation table of PAC-13 permeable asphalt mixture with chopped basalt fiber is as follows.

[0036] PAC-13 Permeable Asphalt Mixture Gradation Through Rate of Each Screen Hole

[0037]

[0038] Step 2: Determine the initial oil-stone ratio:

[0039] The initial oil-stone ratio of the permeable asphalt mixture PAC-13 is determined with reference to the thickness of the adsorbed asphalt film on the surface of the mineral material specified in the CJJ / T 190-2012 "Technical Specification for Permeable Asphalt Pavement". The initial oil-stone ratio is 4.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com