A fully prefabricated composite bridge deck structure

A technology for combining bridge decks and bridge decks, which is applied to bridges, bridge construction, bridge parts, etc., can solve problems such as fatigue cracks and construction periods, and achieve the effects of easy reuse, easy disassembly, and avoiding concrete flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of the specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

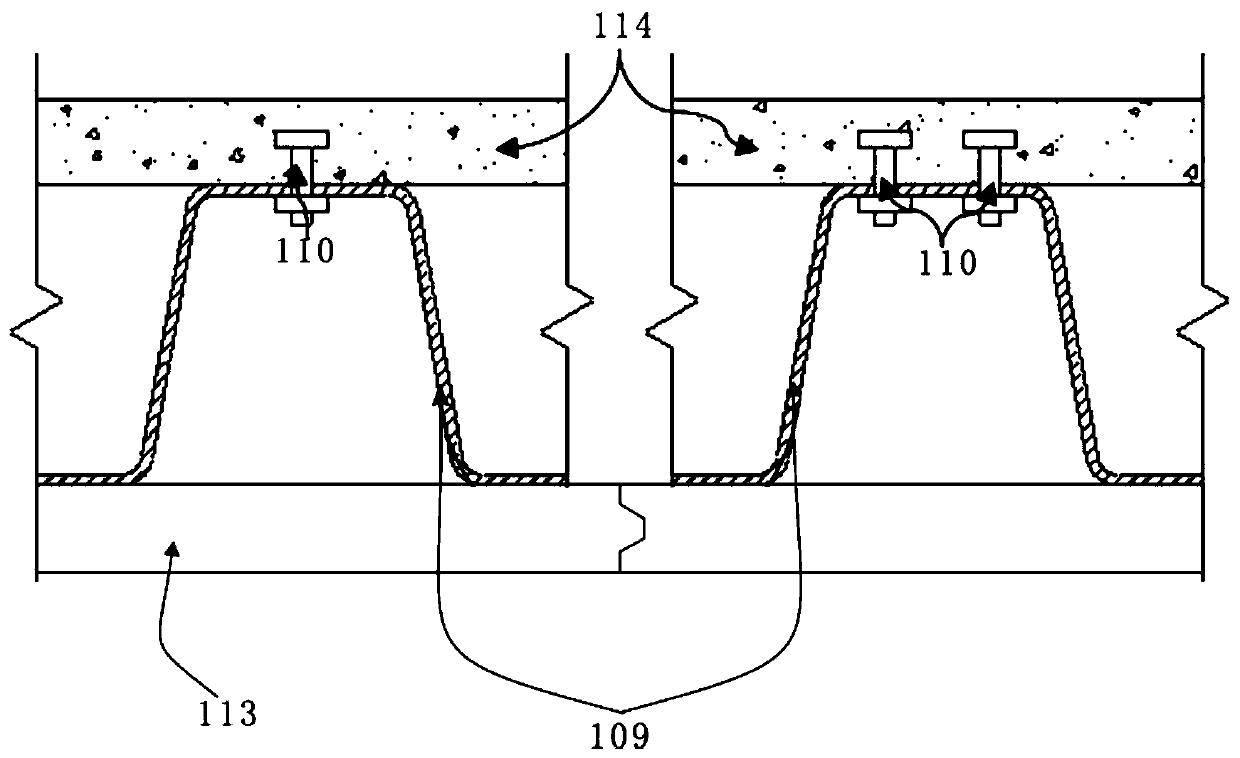

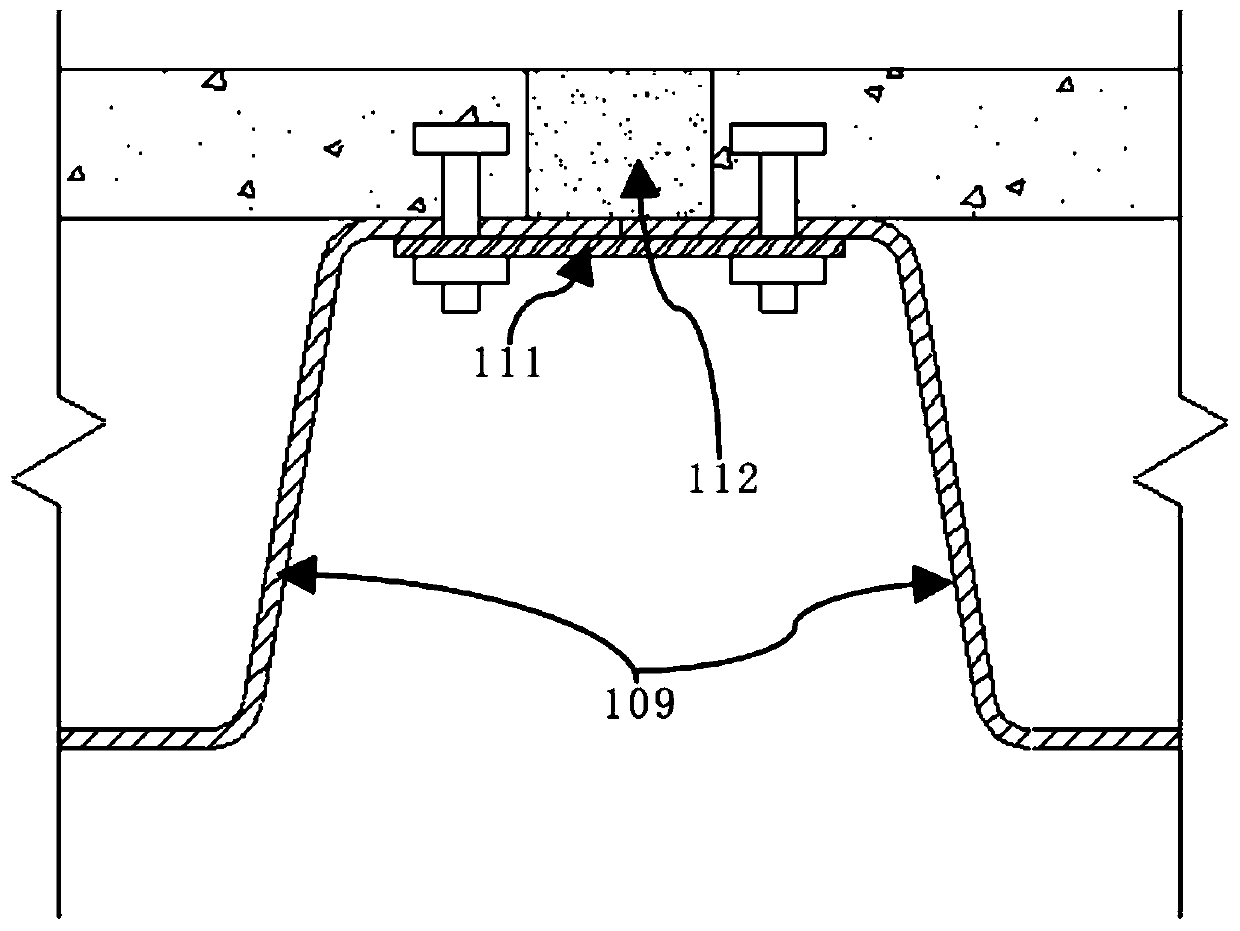

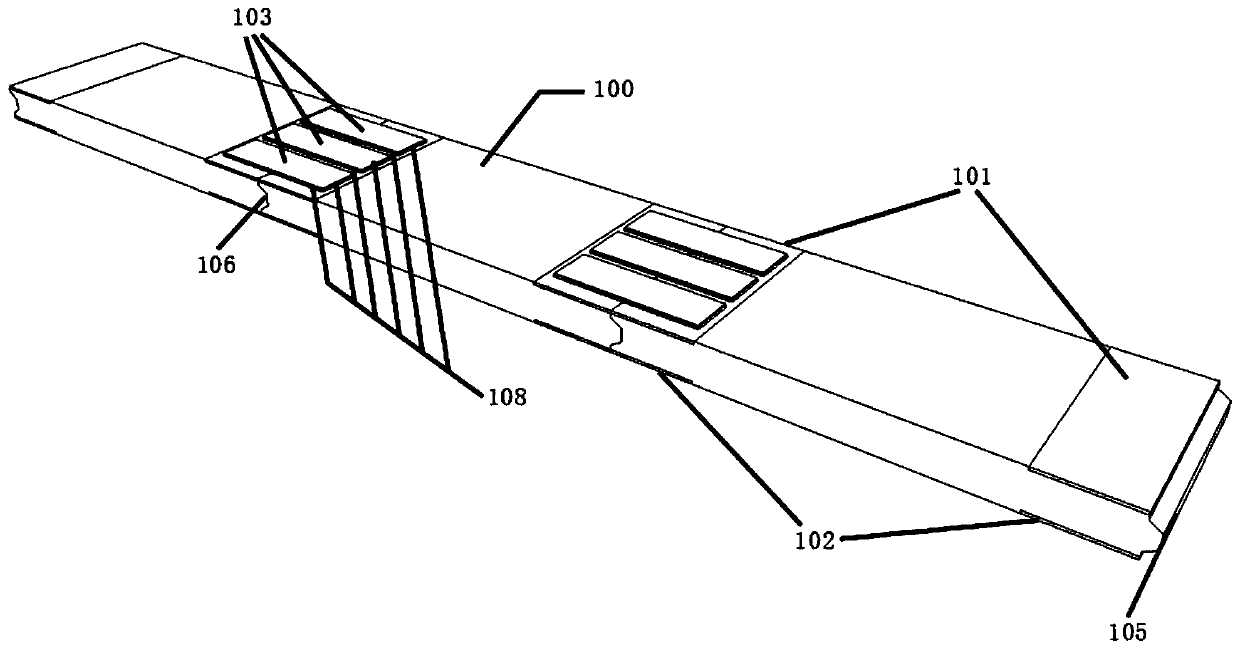

[0022] According to an embodiment of the present application, refer to figure 1 , the fully prefabricated composite bridge deck structure of this scheme includes several prefabricated thin-layer UHPC bridge decks 114, corrugated steel plates 109 and support components 113, wherein the prefabricated thin-layer UHPC bridge decks 114, corrugated steel plates 109 and support components 113 are from top to bottom They are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com