Full-automatic universal material testing system

A material testing and material testing machine technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of difficulty in ensuring the consistency of loading positions, high training costs, equipment pinching, etc., to improve accuracy and repeatability, The effect of eliminating artificial interference factors and reducing processing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

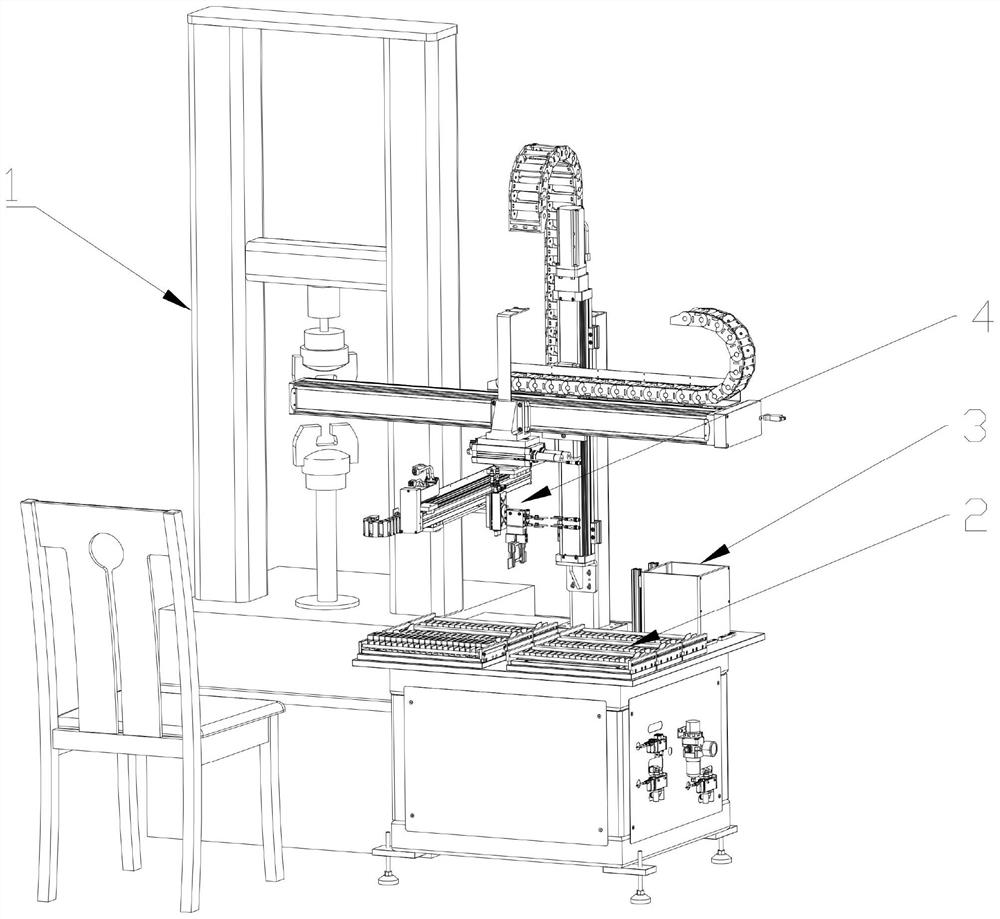

[0075] Please refer to figure 1 As shown, it is a schematic structural view of the fully automatic universal material testing system of the present invention. The fully automatic universal material testing system includes a universal material testing machine 1, a sample material box 2, a waste sample collection device 3, a grabbing mechanism 4, a size measuring device 5, and a control module;

[0076] The universal material testing machine 1 is used to measure the tensile, tearing, bending, compression and other tests of the sample;

[0077] Such as Figure 5 , Figure 6 As shown, the sample material box 2 includes a material box bottom plate 2-1 and side walls 2-2 that are relatively arranged on both sides of the material box bottom plate 2-1, and the described material box bottom plate 2-1 is provided with several A sample storage position 2-3 also includes a limit guide rod 2-4, the side wall 2-2 is provided with a long circular groove 2-2-1, and the limit guide rod 2-4 ...

Embodiment 2

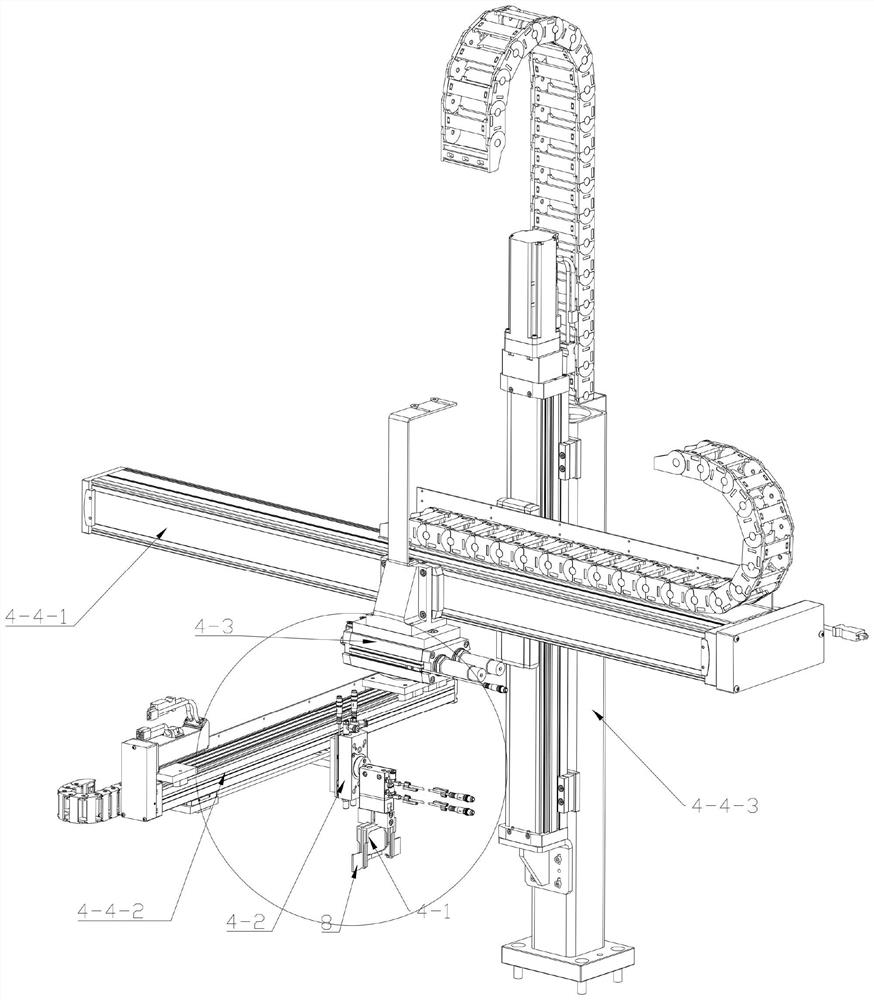

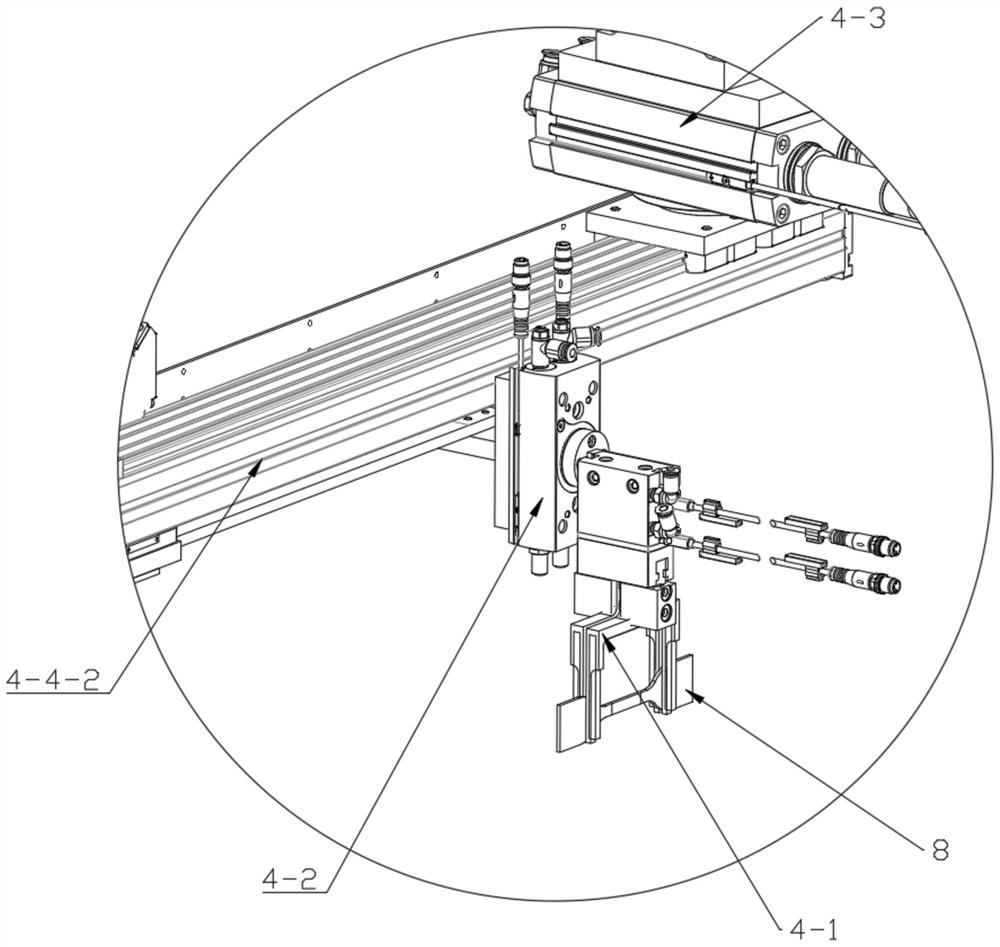

[0092] Different from Embodiment 1, this example also includes a size measuring device 5, such as Figure 7 as shown, Figure 8 yes Figure 7 Enlarged view of middle clamping mechanism 4-1.

[0093] Such as Figure 9 , Figure 10 As shown, the size measuring device 5 includes a measuring base 5-1, a sample limiting structure 5-2, a measuring device driving mechanism 5-3 and a thickness measuring device 5-4, and the sample limiting structure 5- 2. Set it on the measuring base 5-1, and restrict the displacement of the sample 8 to be measured in only one degree of freedom according to the shape of the sample 8 to be tested;

[0094] The thickness measuring device 5-4 is arranged at the output end of the measuring device driving mechanism 5-3;

[0095] The measuring device driving mechanism 5-3 is arranged on the measuring base 5-1; the measuring device driving mechanism 5-3 is a measuring device driving cylinder, and the thickness measuring device 5-4 is connected with the m...

Embodiment 3

[0098] Such as Figure 13 As shown, different from Embodiment 1 and Embodiment 2, in this example, the rotating mechanism 4-2 is fixed on the end of the extension plate 4-5, and the other end of the extension plate 4-5 is fixed on the electric servo slide On the block, the electric servo slider is arranged on the Y-axis lead screw nut of the Y-axis servo mechanism 4-4-2. The extension plate has a compact structure, and the extension plate can be used to deliver the clamping mechanism to the space that the relatively bulky three-axis servo system cannot enter, such as the working position of the universal material testing machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com