Dry quenching primary dust removal coke powder waste heat recovery method and device

A waste heat recovery device and waste heat recovery technology, which are applied in the field of high-quality waste heat recovery of coke powder from coke oven CDQ primary dust removal and coke powder waste heat recovery from primary CDQ dust removal, which can solve the problem of low stability strength, low fracture strength, inability to High-quality recycling, high safety hazards, etc., to slow down the speed of coke extraction, achieve high-efficiency recycling, and eliminate fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

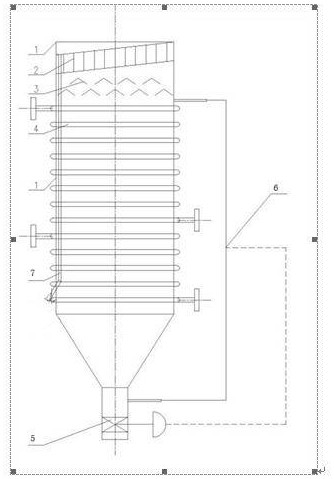

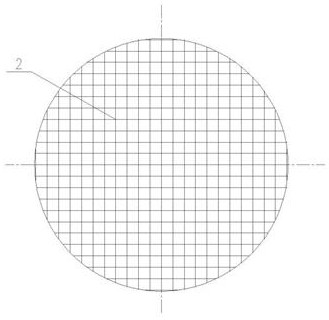

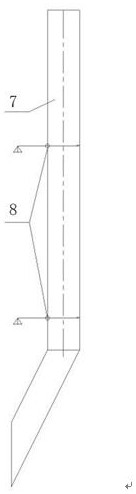

[0027] The present invention relates to a method for recovering waste heat of coke powder from CDQ primary dedusting. The method is to sink the primary dedusting coke powder of CDQ to the outlet of the ash hopper to control its flow rate, establish the coke powder material level of the ash hopper, and distribute the coke powder in a triangular distribution. The waste heat recovery heat exchange tube is buried under the coke powder material level. As the coke powder is slowly discharged, the hot coke powder slowly descends, and the coke powder descends and flows into contact with the heat exchange tube. The high-temperature coke powder transfers heat to the heat exchange tube. The working medium in the pipe; the material level control system controls the intermittent flow of coke powder in the dry quenching coke dust removal in the ash hopper by adjusting the flow rate of the control valve, and controls the coke powder flow to be continuously and slowly discharged, and then contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com