A low-temperature bending and torsion tester and testing method for resistive variable film

A resistive film and tester technology, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of flexible film damage, lack of professional fatigue testing tools, and difficult to control the number of bending times. Convenient operation, simple structure, and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

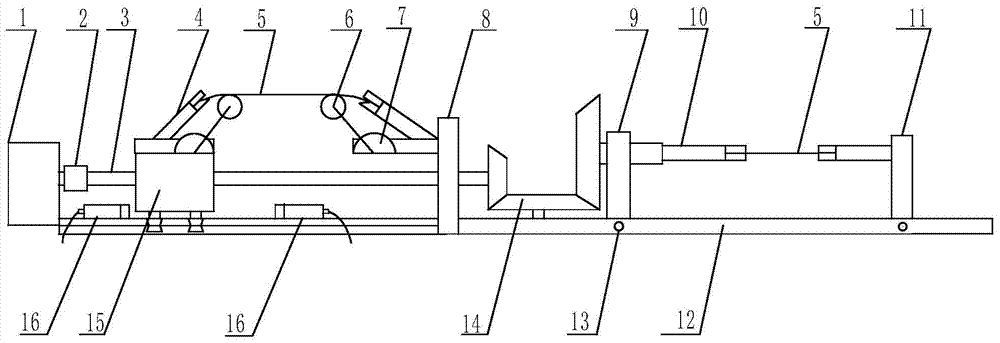

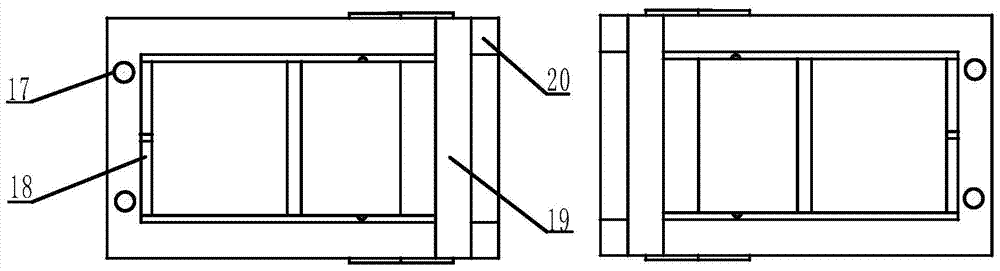

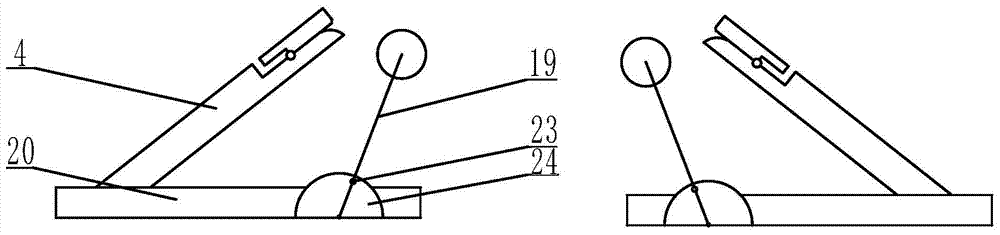

[0049] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] A low-temperature bending and torsion tester for resistive thin film, comprising:

[0051] A bending and torsion device that can bend and twist the resistive film at an adjustable angle;

[0052] A measurement and control system that controls the bending times, bending speed, bending degree, and twisting angle of the bending and twisting device, and measures the volt-ampere characteristic curve of the resistive film during the bending and twisting test;

[0053] According to the control instructions of the measurement and control system, a low-temperature system that provides the low-temperature environment required for the bending and torsion test of the resistive film;

[0054] The bending and twisting device is placed inside the low temperature system, and the measurement and control system is connected with the low t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com