Bowstring-truss-type plane gate

A plane gate, truss-type technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of large steel consumption, large end thickness, large volume of door grooves, and unbalanced internal forces of components. To achieve the effect of beautiful appearance, balanced force and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

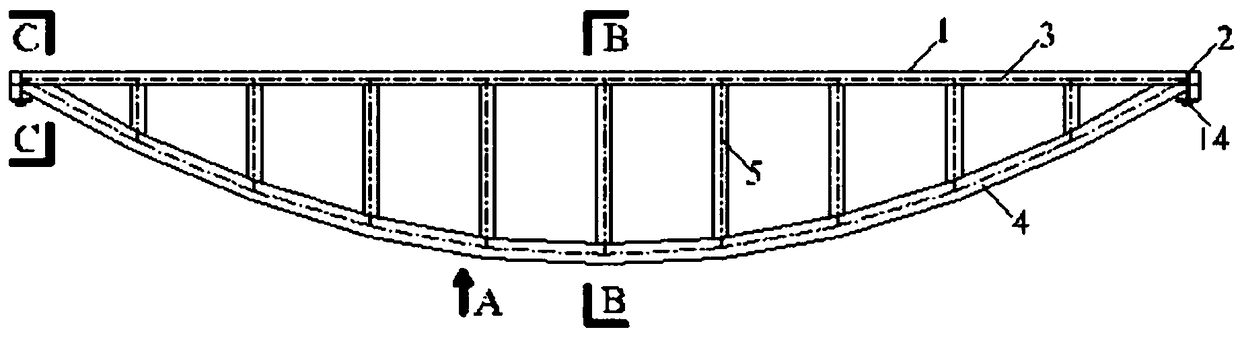

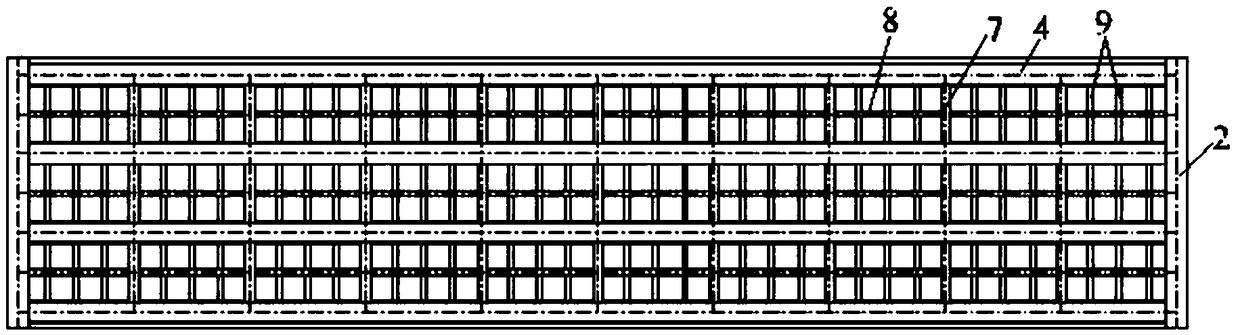

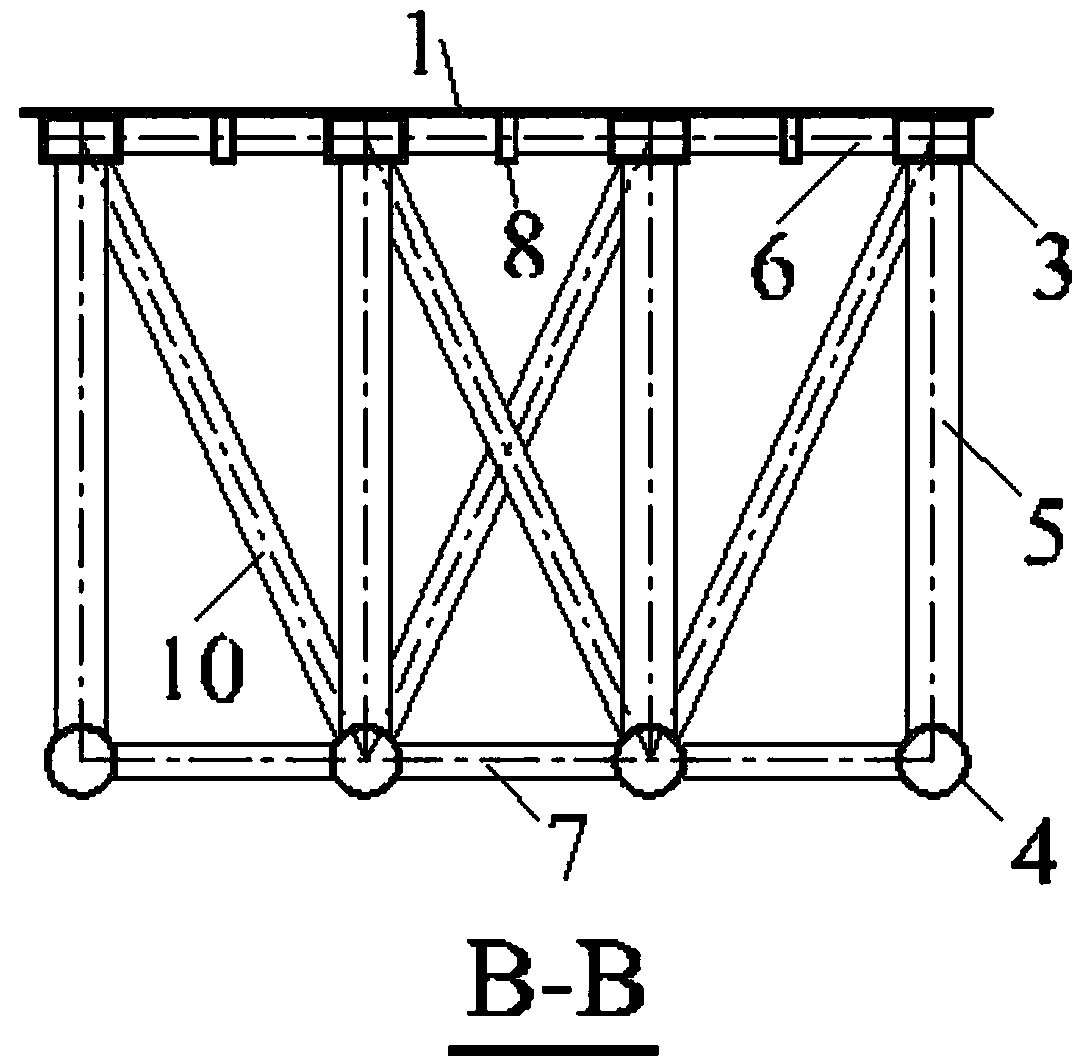

[0027] A bowstring truss type plane gate, comprising a panel 1, four bowstring truss main girders, panel area rib beams for reinforcing the bottom of the four bowstring truss main beams, and four bowstring truss girders for reinforcing the four bowstring truss girders. The main beam reinforcement mechanism at the top of the main beam is used to strengthen the supporting stiffeners at both ends of the bowstring truss type main beam described in the four lines, and the upper ends of the bowstring truss type main beams described in the four lines are fixed in an arrangement of equal intervals or dense at the bottom and sparse at the top The panel 1 is connected, the panel area lattice rib beam is fixedly arranged between the bottoms of the four bowstring truss type main beams, and the main beam reinforcement mechanism is fixedly arranged on the top of the four bowstring truss type main beams, The supporting stiffeners are fixedly arranged at both ends of the four bowstring truss-t...

Embodiment 2

[0046] Such as Figure 7 As shown, this embodiment is basically the same as Embodiment 1, except that this embodiment includes six bowstring truss main girders, forty-eight main girder web members 5, twelve tie rods 7, five horizontal rib beams 8, Thirty-nine vertical rib beams 9; the main girder webs 5 of the bowstring truss type main girder adopt single-slope webs, and the 4 mid-span internodes adopt cable-stayed webs, and the 4 adjacent to the left and right The baroclinic web bars are used for the internodes, and the two internodes at the left and right ends are still fasting web bars. Compared with Embodiment 1, the in-plane rigidity of the gate in this embodiment is greatly improved.

[0047] Further, it includes a single inclined web member 15, the front end of the main beam web member 5 on the left side and the main beam member on the right side among several adjacent main beam web members on the bowstring truss type main girder. The rear ends of the webs 5 are all f...

Embodiment 2

[0050] Such as Figure 8 As shown, this embodiment is basically the same as Embodiment 1 and Embodiment 2, except that this embodiment includes ten bowstring truss main girders, one hundred main girder web members 5, sixteen tie rods 7, nine There are 8 horizontal rib beams and 54 vertical rib beams 9; the main girder web 5 of the bowstring truss type main girder adopts cross-type web members, but the two internodes at the left and right ends are still hollow-type web members . Compared with Embodiment 2, the in-plane stiffness of the gate in this embodiment is further improved.

[0051] Further, including cross-type webs 16, the main beam webs 5 on the left side and the main beam webs 5 on the right side among several adjacent main beam webs on the bowstring truss type main girder A cross-type web bar 16 is fixedly connected therebetween.

[0052] Other parts in this embodiment are the same as Embodiment 1 and Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com