Cyclone bottom-flow energy dissipation device in graded tailing filling system and energy dissipation method thereof

A technology of energy dissipator and cyclone, which is applied in the direction of filling, earth square drilling, mining equipment, etc., can solve the problems of liquid surface impact and disturbance in sand bins, achieve the elimination of impact and disturbance, reduce impact and disturbance, and improve The effect of natural settlement environment and enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

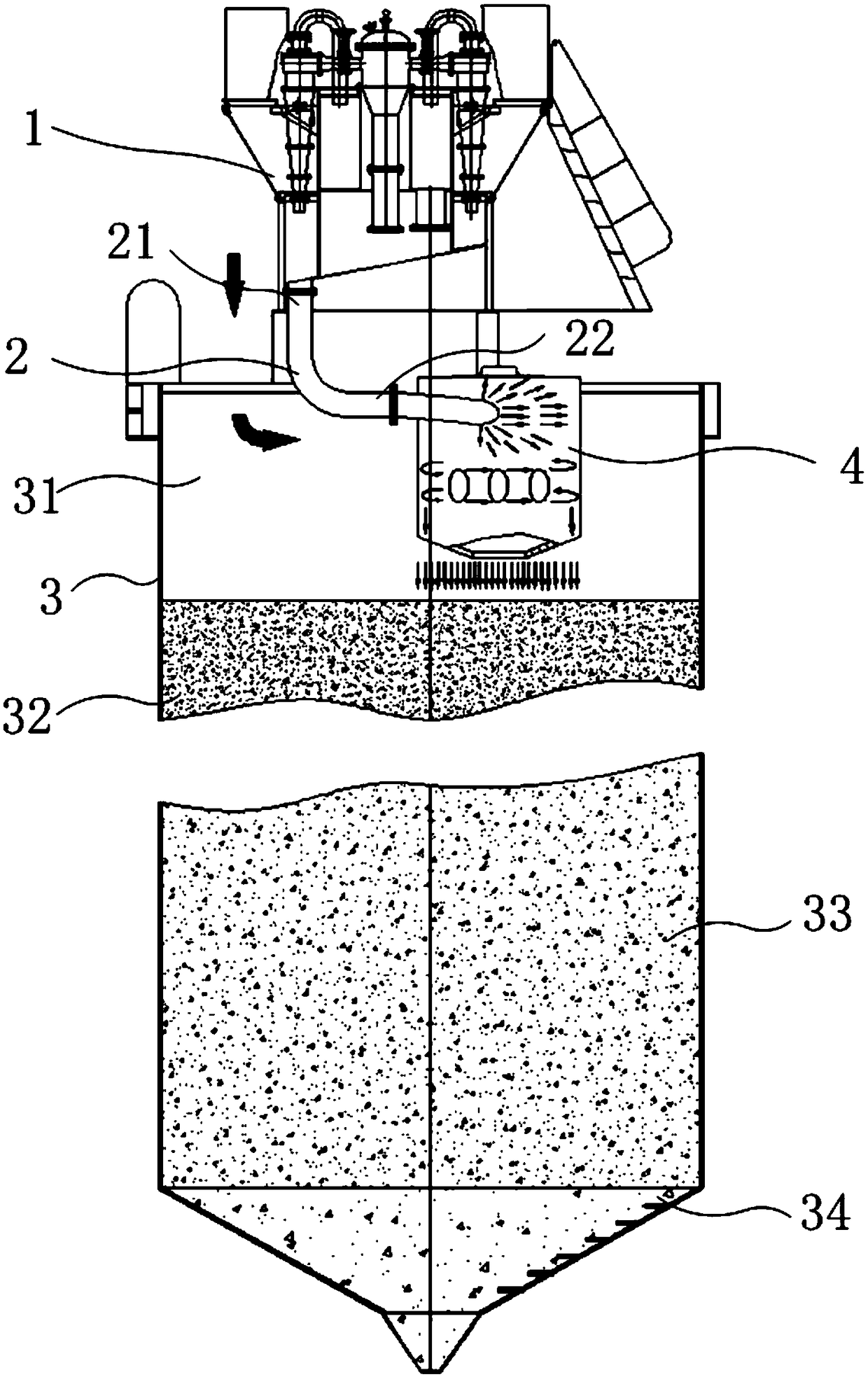

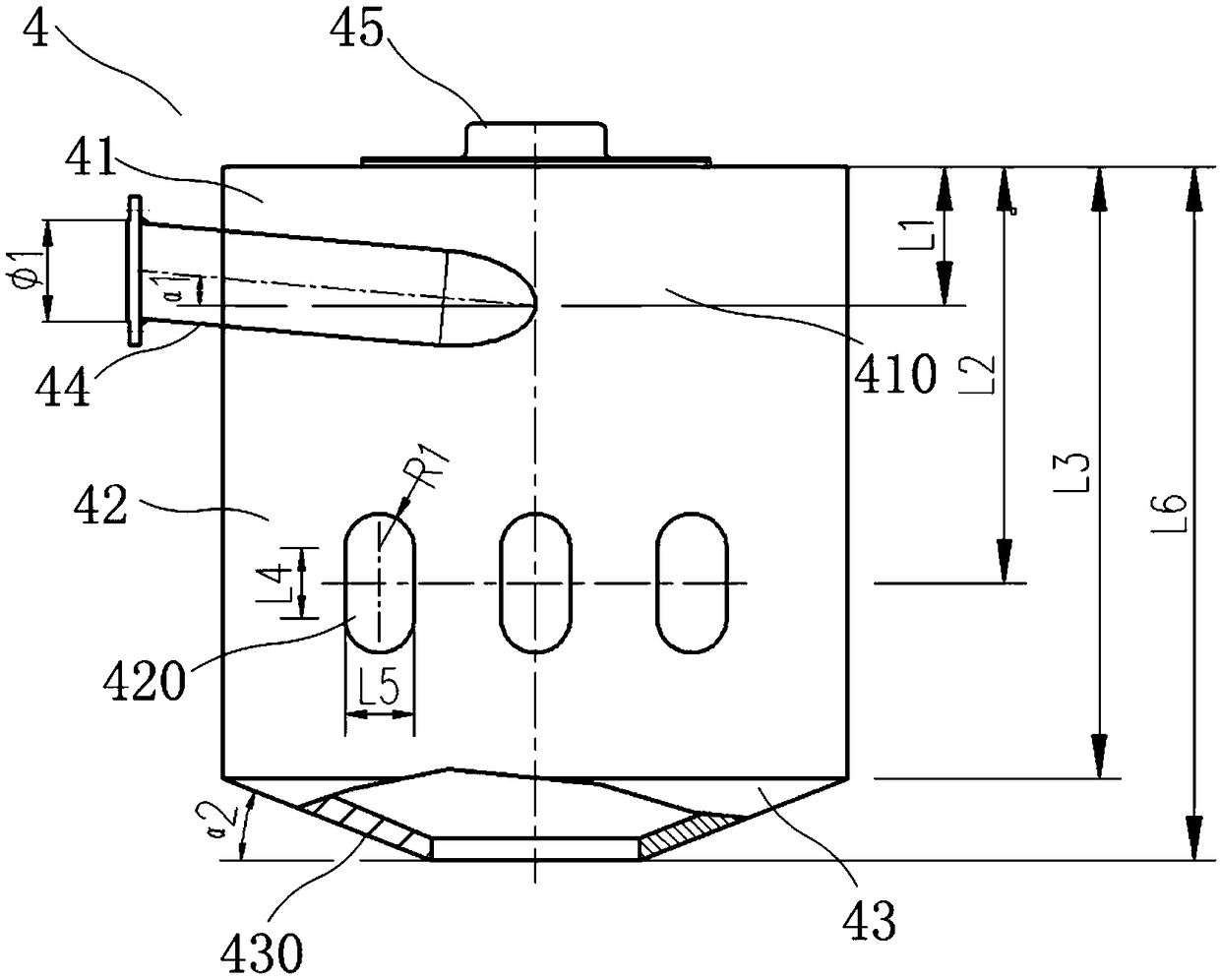

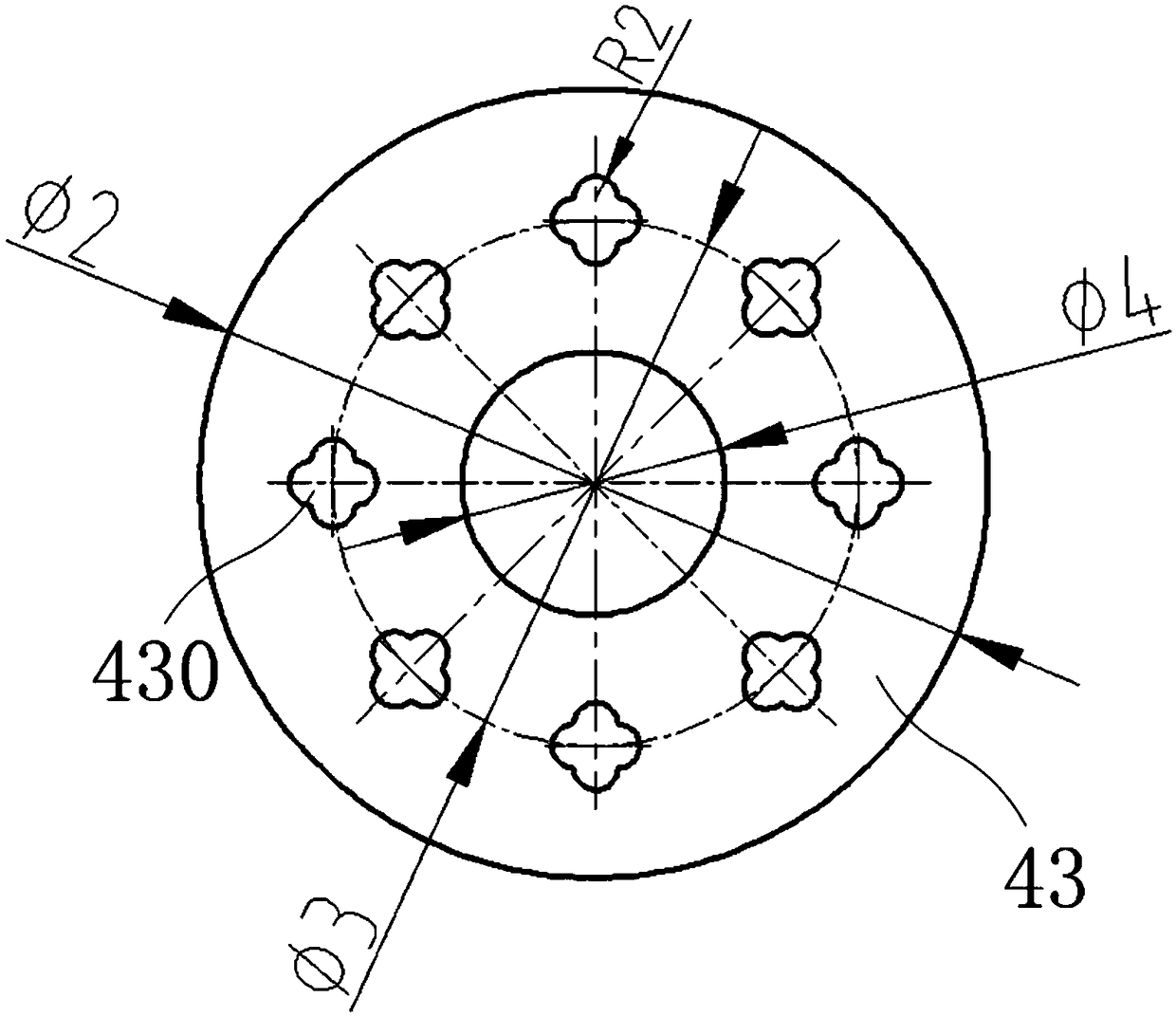

[0068] Such as figure 1 As shown, the embodiment of the present invention provides a cyclone underflow energy dissipator in a graded tailings filling system, which can change the trajectory of high kinetic energy fluid and convert the three-dimensional cylindrical free turbulent underflow into a two-dimensional planar free flow. The turbulent jet can quickly attenuate the time-average total motion of the fluid; it can improve the impact and disturbance of the bottom flow of the cyclone on the liquid surface of the sand bin, improve the stability of the concentration of the bottom flow of the sand bin, and ensure the filling quality.

[0069] The cyclone underflow energy dissipator in the graded tailings filling system includes: cyclone (1); material guide pipe (2); three-dimensional sand bin (3); energy dissipator (4); three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com