Cipp field curing repair device and method

A technology of on-site curing and repairing methods, applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of inability to clean the inside of the pipeline, unfavorable installation and curing of the lining pipe, etc., to facilitate the traction installation. Hose, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

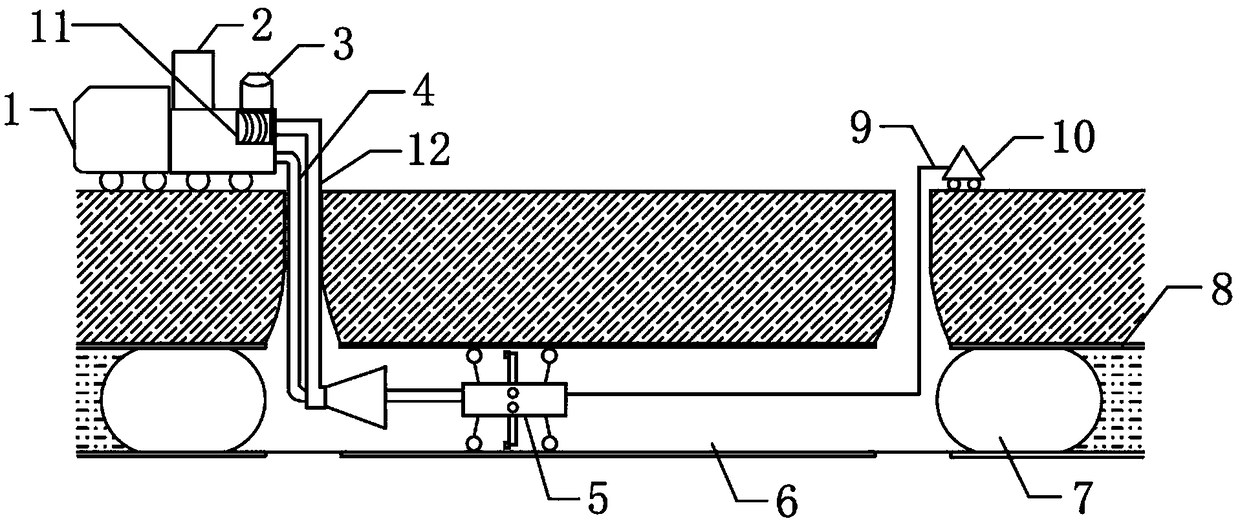

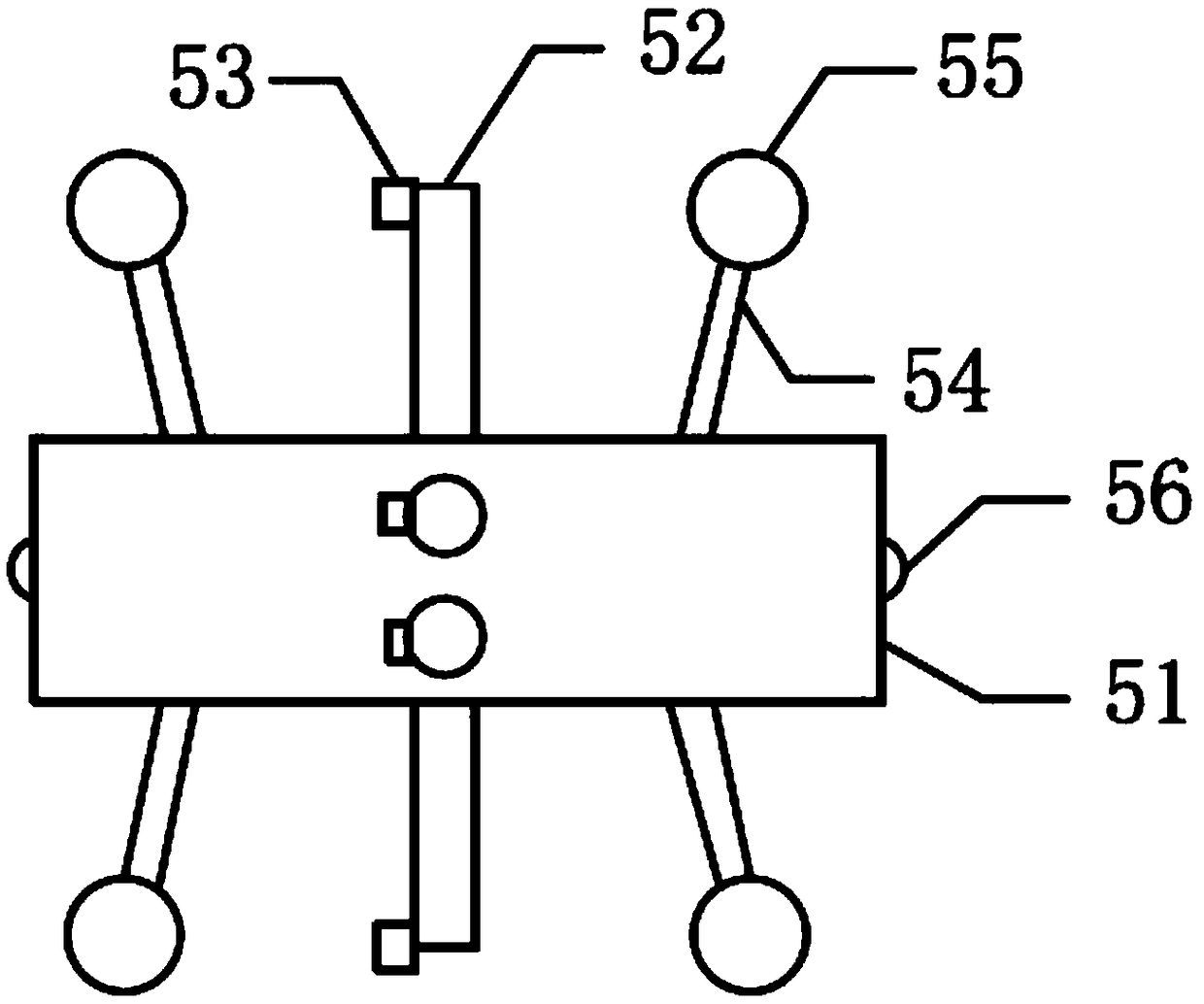

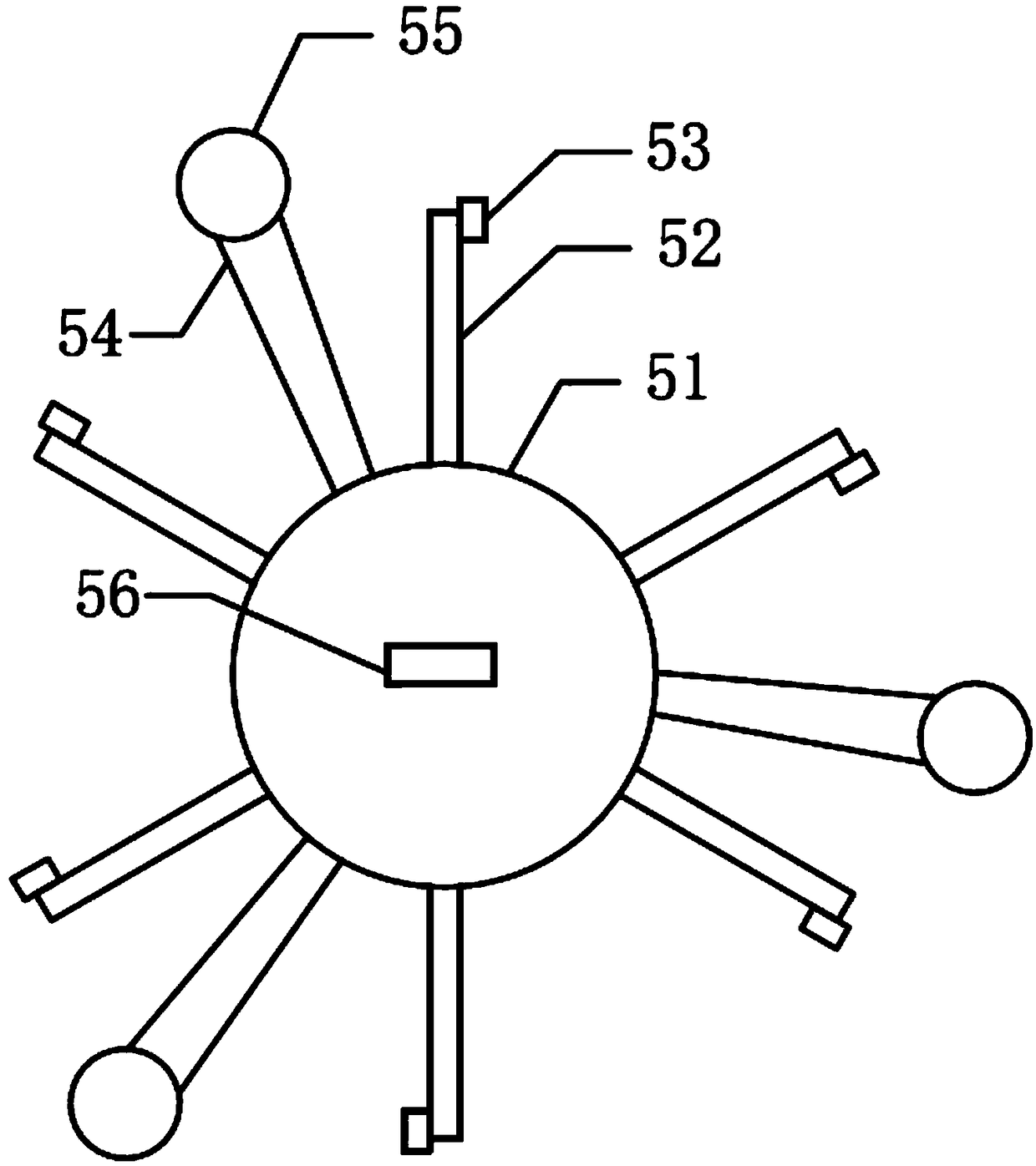

[0037] A cipp on-site solidification repair device, including a transport vehicle 1, a hoist 10, a water blocking air bag 7 and a baking device 5, the transport vehicle 1 is equipped with a liquefied natural gas tank 2, a steam boiler 3 and a blower 11, and the transport vehicle 1 One end of 1 is fixedly connected with a high-temperature-resistant hose 4, and one end of the high-temperature-resistant hose 4 is fixedly connected with a baking device 5, and the baking device 5 is slidably installed in the pipeline 6 to be repaired. One of the blower 11 One end of the air pipe 12 is installed on the pipeline 6 to be repaired, one end of the baking device 5 is connected to the winch 10 through the traction rope 9, and the inside of the high temperature resistant hose 4 is installed with a power supply. line 42, natural gas pipe 32 and control cable 44, the baking device 5 includes a moving block 51, the moving block 51 is fixedly equipped with a fire spray pipe 51 and legs 54, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com