A Correction Method for Fuel Quantity of Supercritical Once-through Boiler by Feedwater Temperature Change

A technology of feed water temperature and once-through boiler, which is applied in the direction of combustion method, fuel supply adjustment, boiler working condition indication, etc., and can solve problems such as boiler efficiency and boiler fuel volume that must be solved at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0140] The present invention will be further described below in conjunction with accompanying drawing and example.

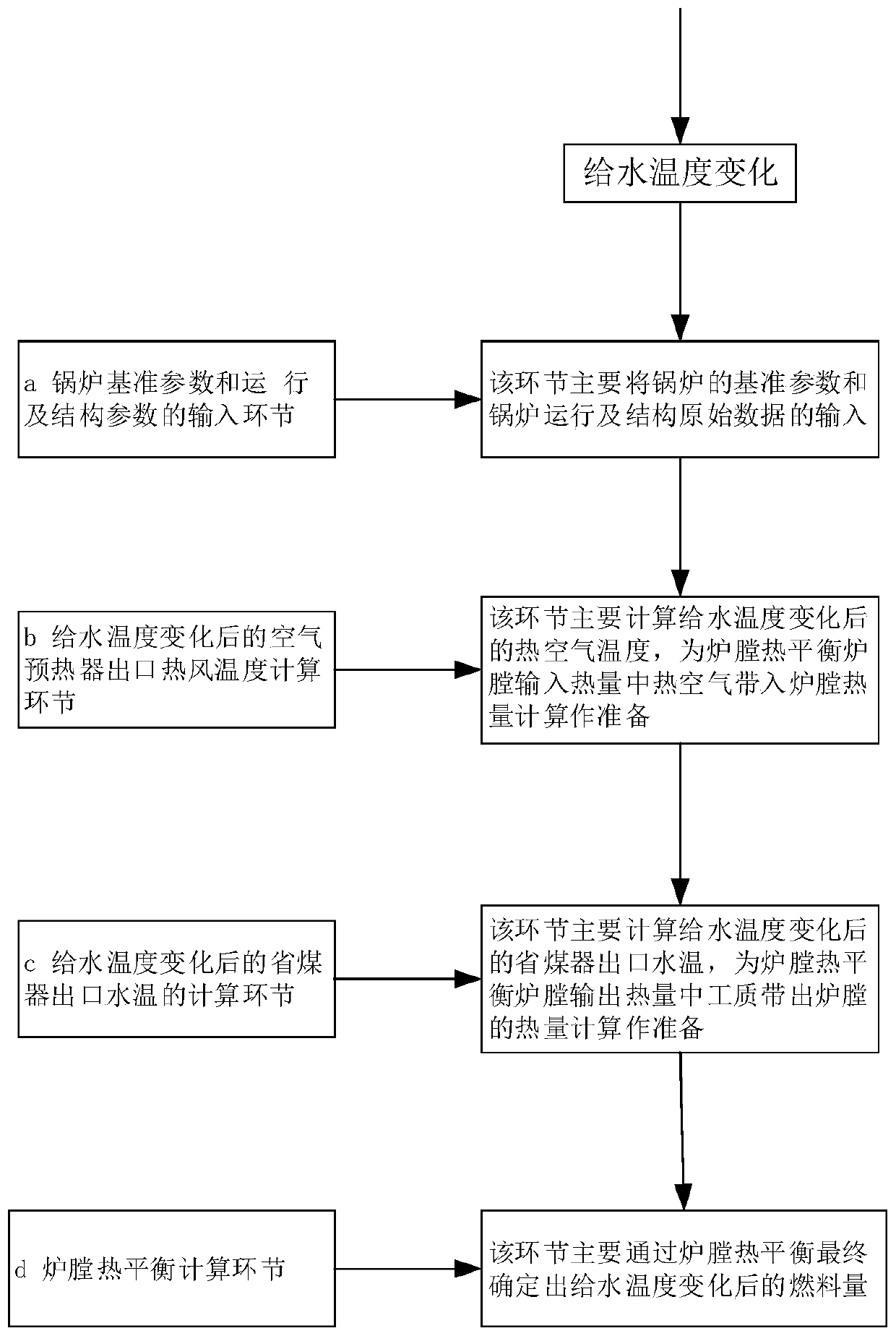

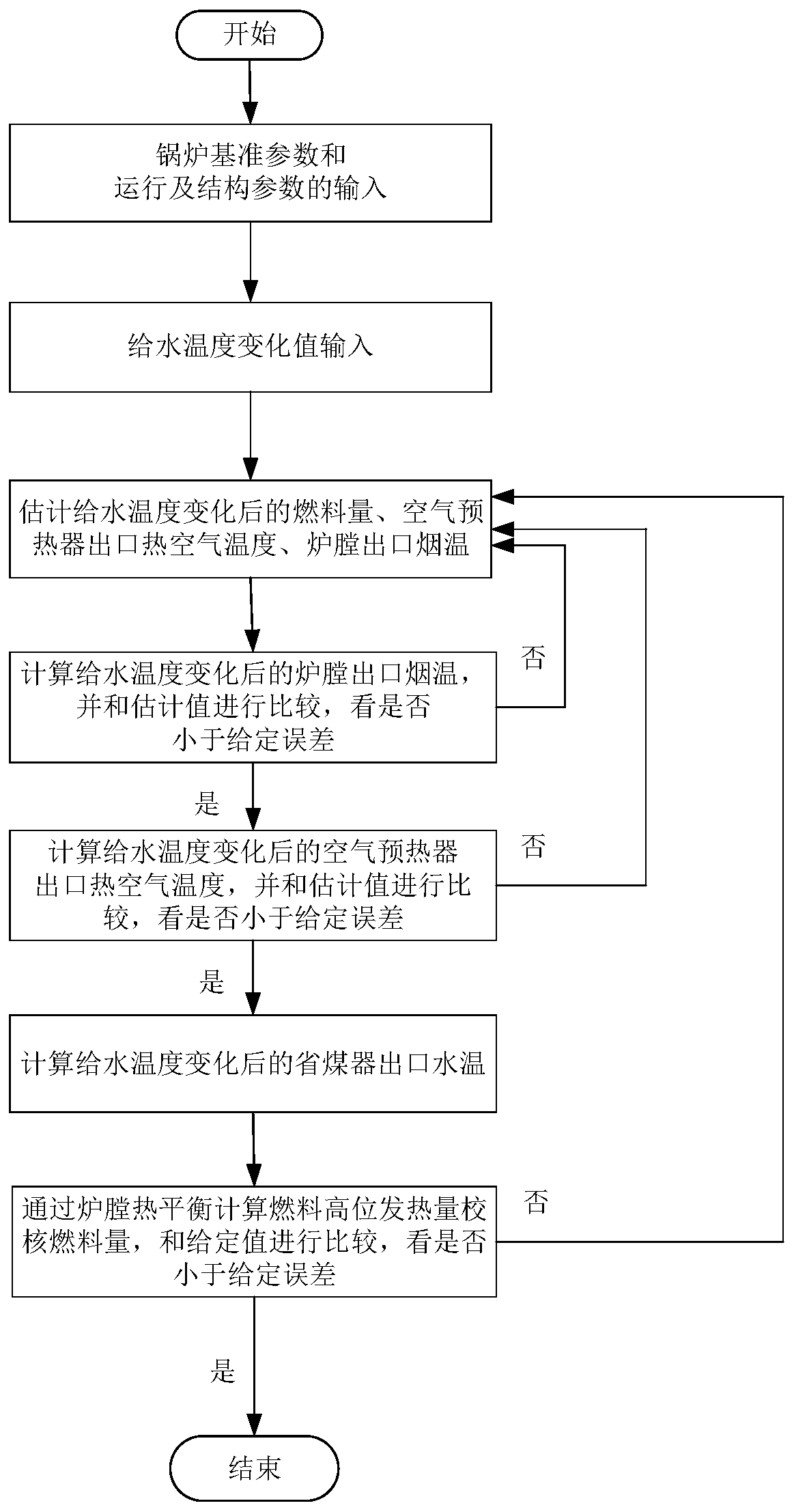

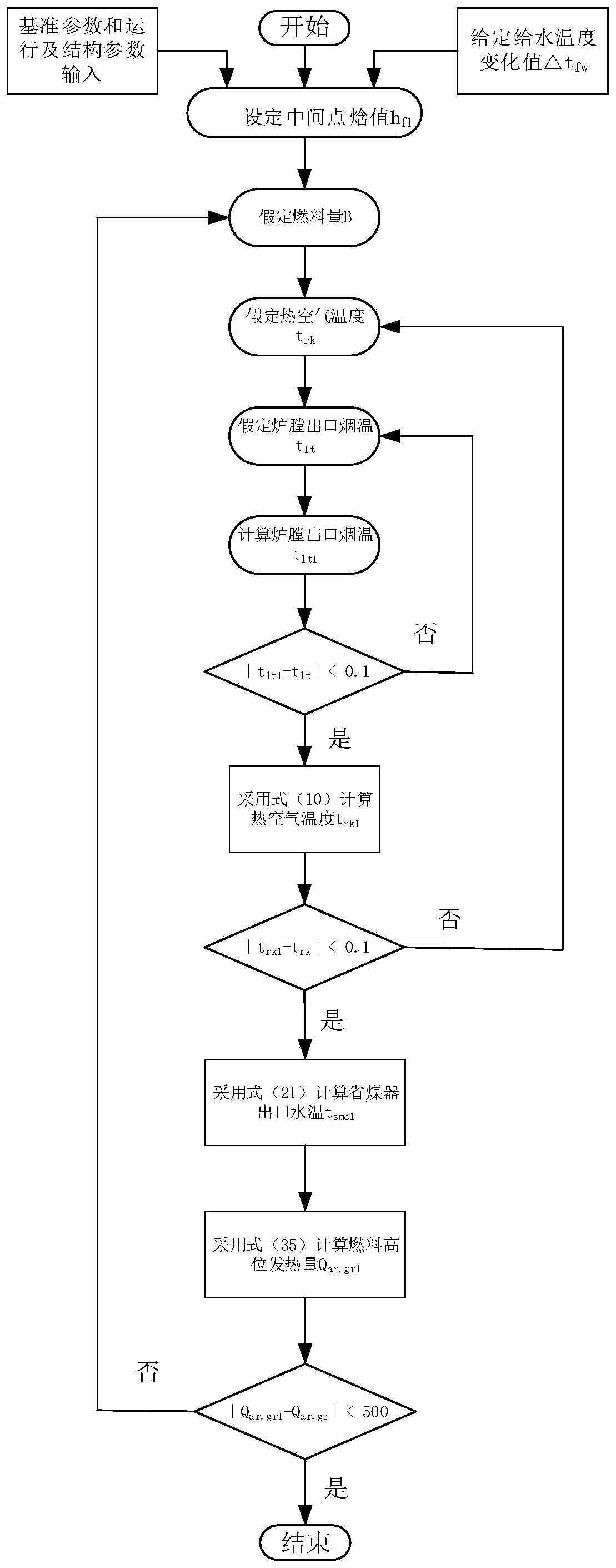

[0141] refer to Figure 1 ~ Figure 3 , a method for correcting the fuel volume of a supercritical once-through boiler with feedwater temperature changes in the present invention mainly consists of the following links, combined with figure 2 and image 3 , the realization of each link needs to be completed through the idea of iterative verification.

[0142] (a) Reference parameter and operation and structure parameter input link:

[0143] This link mainly satisfies the calculation of the corresponding operating parameters after the feedwater temperature changes through the input of the reference parameters and the input of the current operating parameters. Since the reference parameters and operating parameters are important parameters that determine the change of fuel volume, and the load is different, the reference parameters and operating parameters The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com