Damp lubricating powder drying device with good universality

A drying device and lubricating powder technology, which is applied to heating devices, drying solid materials, non-progressive dryers, etc., can solve problems such as product quality decline, incomplete drying, and lubricating powder burnt, and achieve good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

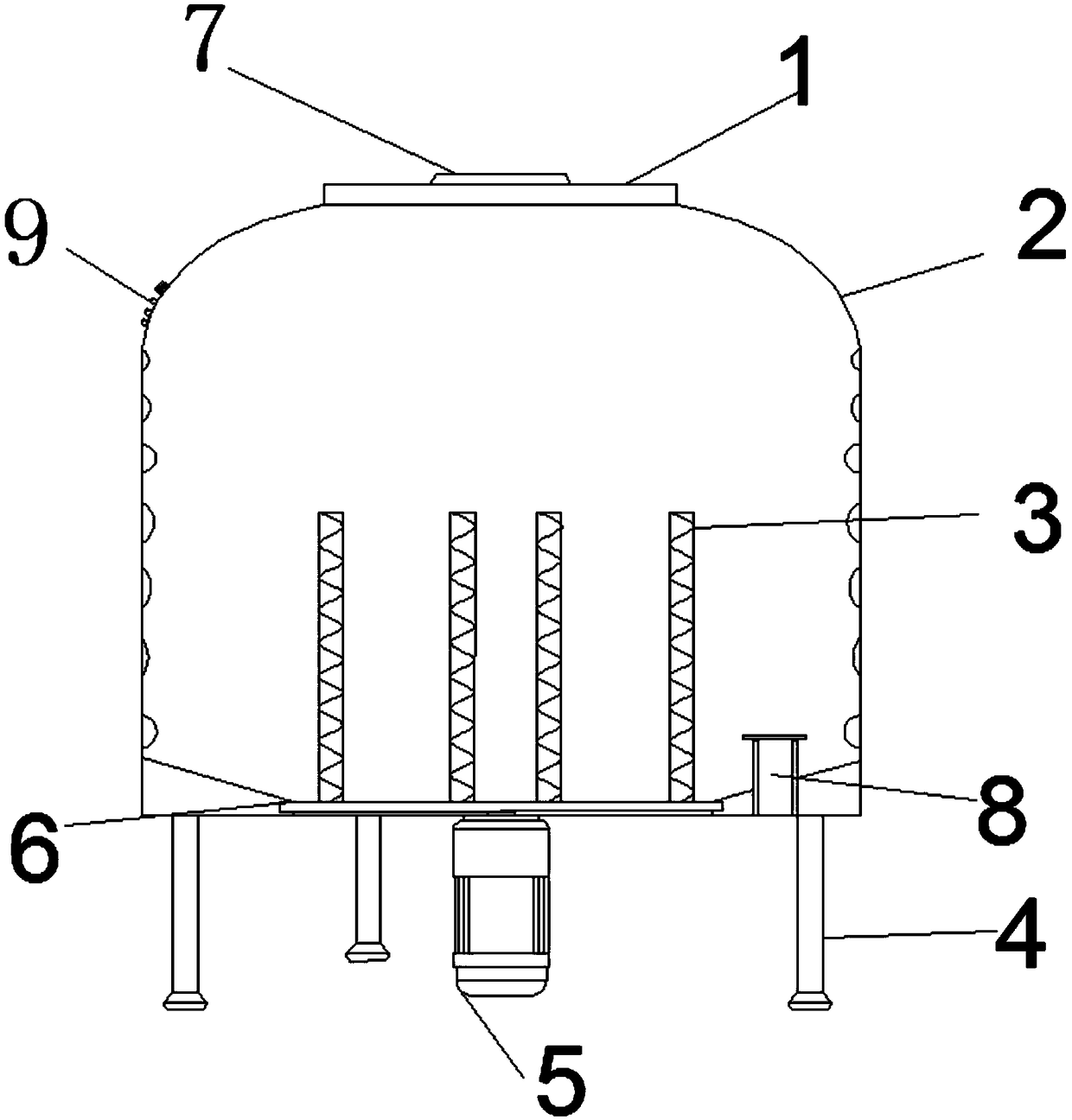

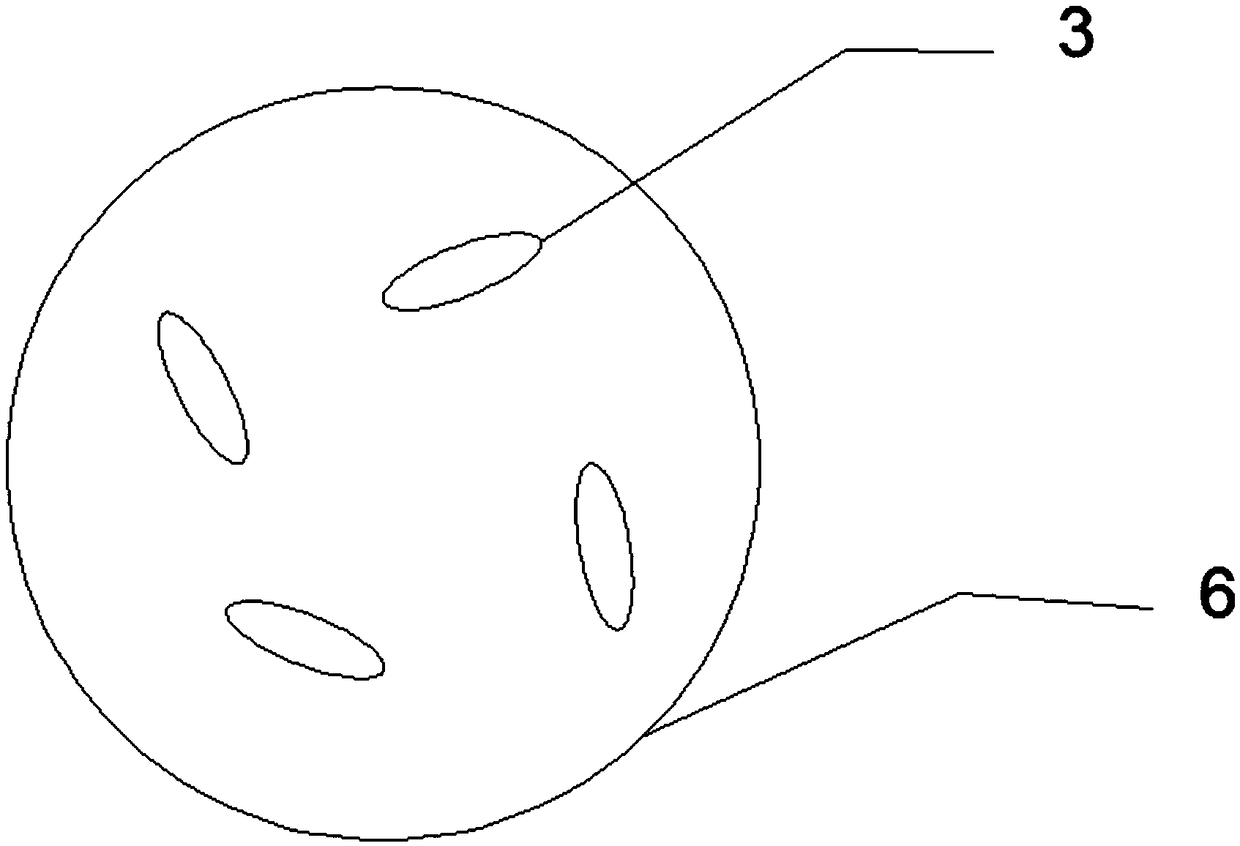

[0017] Embodiment, a kind of damp lubricating powder drying device with good versatility, comprising feeding port cover 1, processing chamber 2, heating rod 3, pillar 4, motor 5, rotating disk 6, power switch 9, exhaust port 7 and discharge Port 8, the feeding port cover 1 is fixed by buckle directly above the processing chamber 2, and the feeding port cover 1 can be opened to feed the inside of the processing chamber 2. When the steam is generated, the exhaust port 7 can discharge the gas in a timely and effective manner. The filter device is installed inside the exhaust port 7. The filter device can effectively prevent the steam from flying out with the lubricant powder and pollute the air. The inside of the processing chamber 2 is installed by bearings. There is a rotating disk 6, and a stopper is arranged around the rotating disk 6. The stopper is installed on the wall of the processing chamber 2 through threads, which can effectively prevent the lubricating powder from ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com