On-line Monitoring System of Train Axle Temperature Wheel Temperature Based on Fiber Bragg Grating

A technology of fiber grating and monitoring system, which is applied to thermometers, thermometers, measuring heat and other directions with physical/chemical changes, can solve problems such as electromagnetic radiation and interference, and achieve the effects of strong waterproof ability, high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

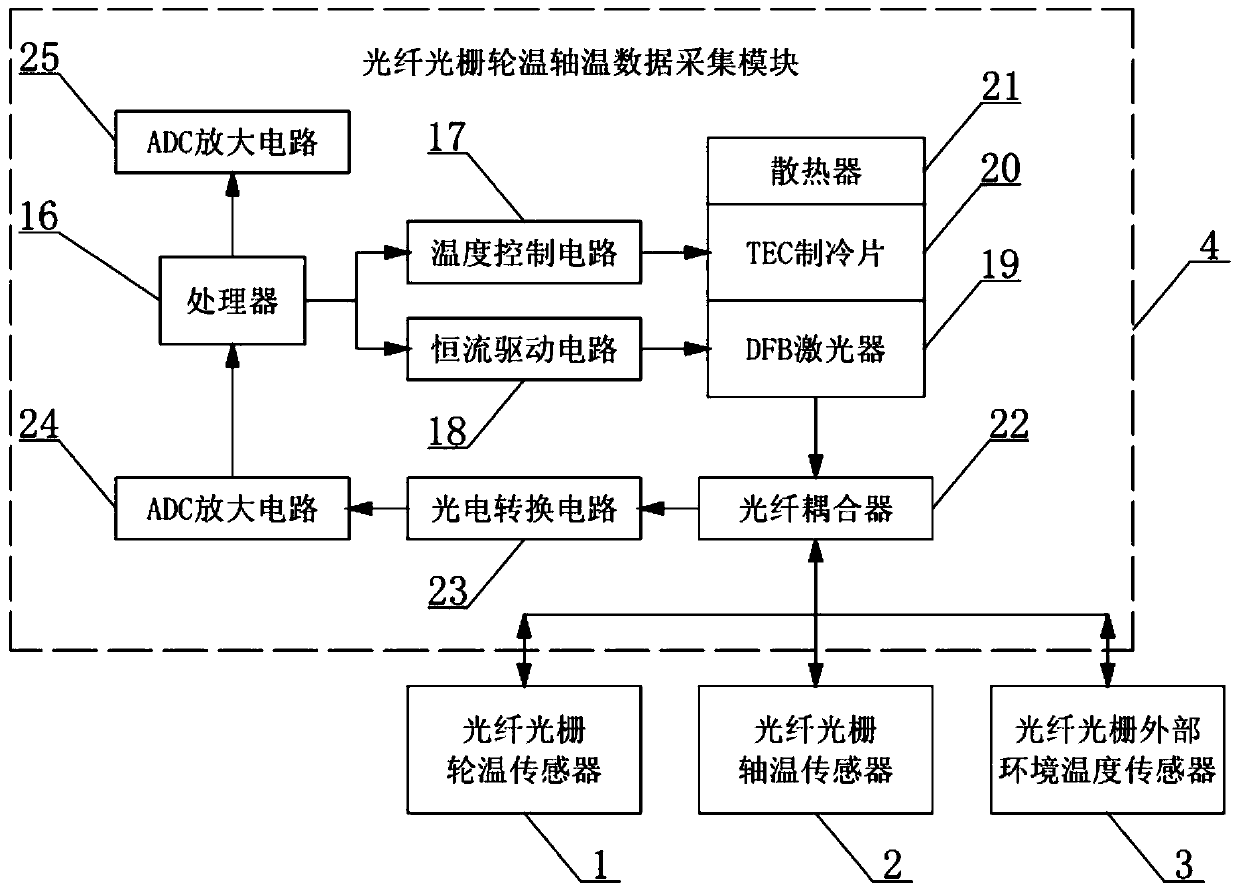

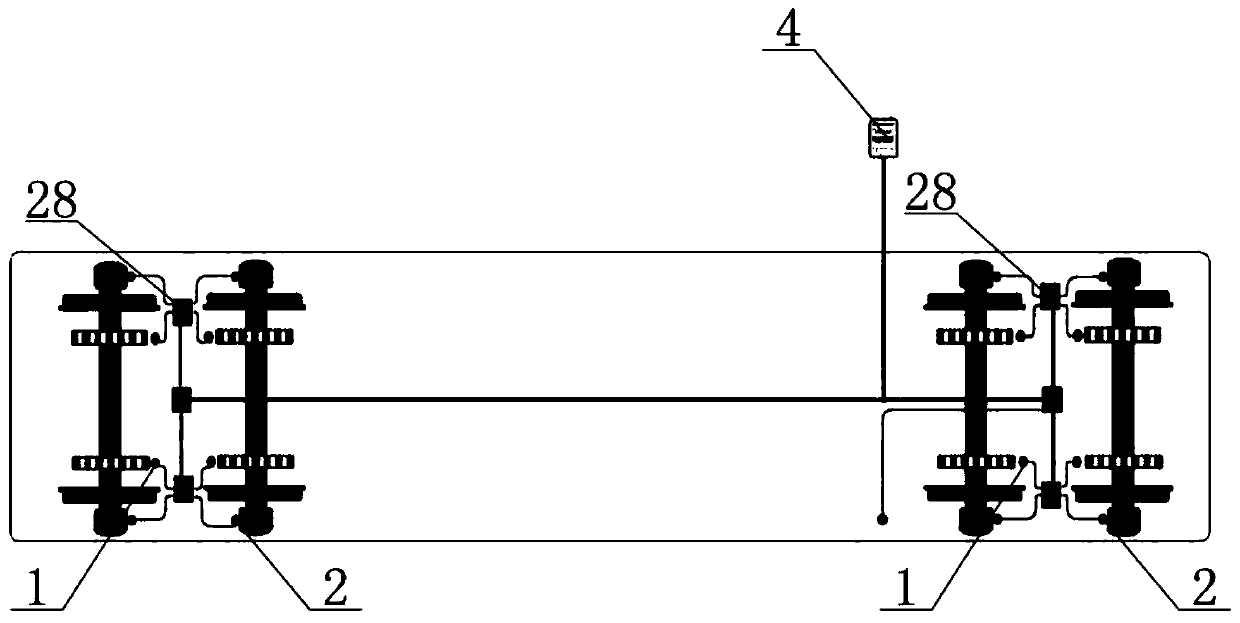

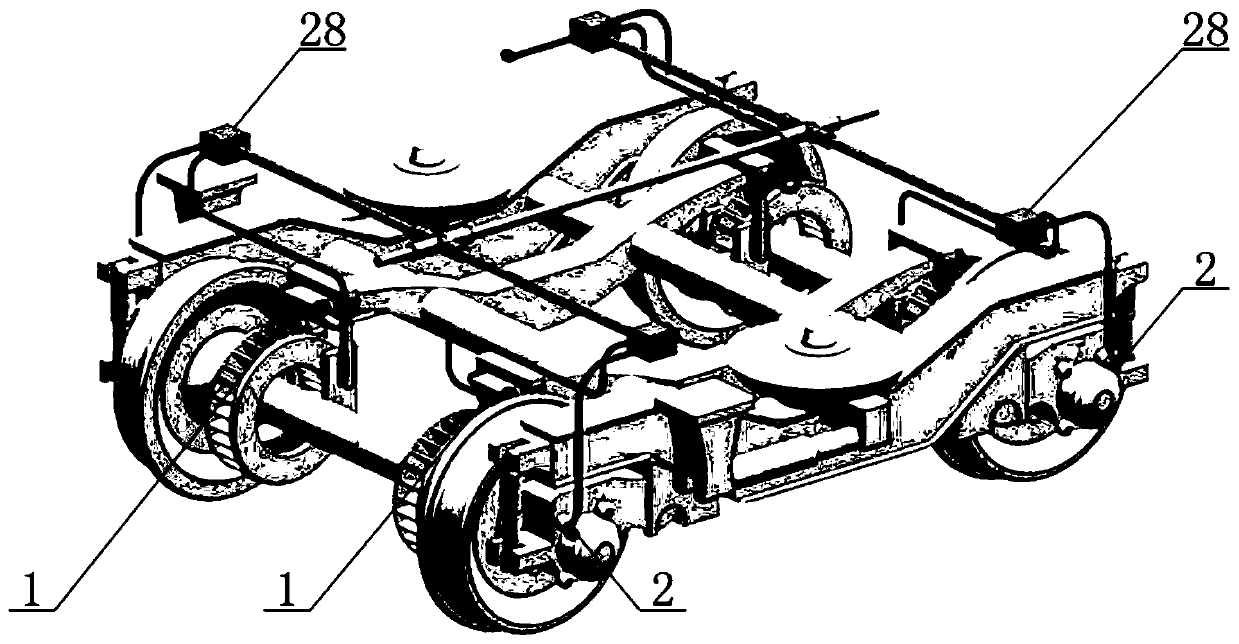

[0027] Such as figure 1 As shown, the fiber grating-based train shaft temperature wheel temperature online monitoring system of the present invention includes

[0028] A positive integer number of fiber grating wheel temperature sensors 1 are installed on the axle for real-time acquisition of the axle temperature;

[0029] A positive integer number of fiber grating shaft temperature sensors 2 are installed on the carriage and facing the wheels for real-time acquisition of the temperature of the wheels;

[0030] The fiber grating external environment temperature sensor 3 is installed on the outside of the compartment for real-time collection of the external environment temperature;

[0031] And fiber grating wheel temperature shaft temperature data acquisition module 4, used to provide the working light source of fiber grating wheel temperature sensor 1, fiber grating shaft temperature sensor 2 and fiber grating external environment temperature sensor 3; receive fiber grating ...

specific Embodiment approach 2

[0036] The difference between the second embodiment and the first embodiment is that the fiber grating wheel temperature sensor 1 includes a wheel temperature sensor housing 5, a glass window 6, a wheel temperature measuring fiber grating 7 and a blackbody structure 8;

[0037] A side wall of the wheel temperature sensor housing 5 is sealed with a glass window 6; the wheel temperature sensor housing 5 is horizontally provided with a sheet metal substrate 9, one side of the metal substrate 9 is facing the glass window 6, and is in contact with the glass window 6. The black body structure 8 is filled between the glass windows 6; the other side of the metal base 9 is fixed with a wheel temperature measuring fiber grating 7, the wheel temperature measuring fiber grating 7 is located in the wheel temperature sensor housing 5, and the wheel temperature measuring fiber grating 7 The output end of the wheel temperature optical signal is connected to the optical signal input and output ...

specific Embodiment approach 3

[0044] The difference between the third embodiment and the second embodiment is that the insulation structure 10 is filled between the other side of the metal base 9 and the inner wall of the wheel temperature sensor housing 5 .

[0045] Such as image 3 As shown, the lower surface of the metal base 9 is surrounded by a thermal insulation structure 10, and the thermal insulation structure 10 uses high-temperature-resistant aluminum silicate ceramic fiber cotton with a thickness of 10 mm to 12 mm to surround the wheel temperature measuring fiber grating 7 and the metal base 9 to avoid heat. All the heat converted by the black body structure 8 acts on the fiber grating to ensure the measurement accuracy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com