Method and device for measuring dynamic viscosity based on light suspended particles

A technology of dynamic viscosity and measurement method, which is applied in the direction of measuring device, indirect flow characteristic measurement, flow characteristics, etc., to achieve the effect of fast response speed, high measurement accuracy and less measurement error items

Active Publication Date: 2018-10-12

ZHEJIANG UNIV

View PDF6 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method is only suitable for the detection of liquid samples, and requires accurate ca

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

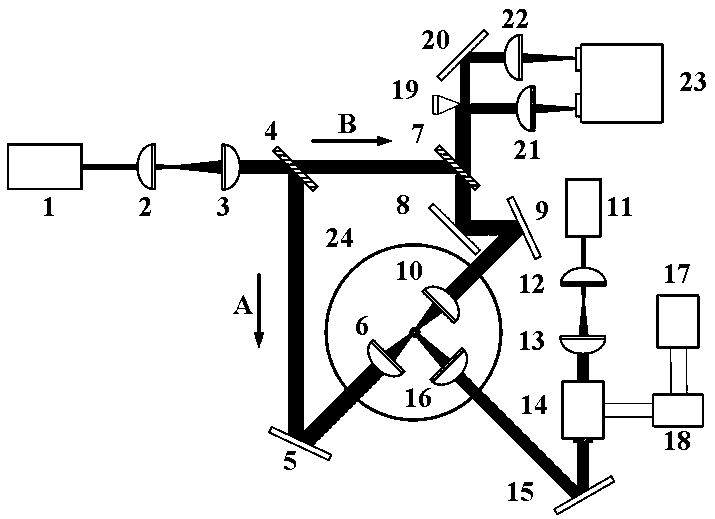

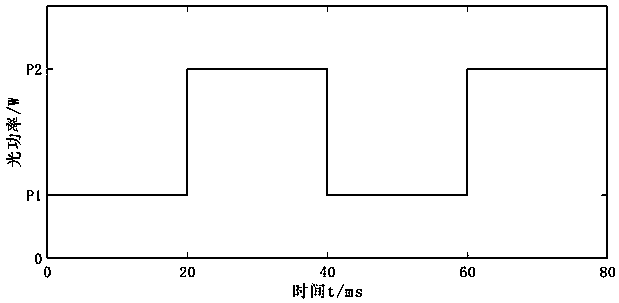

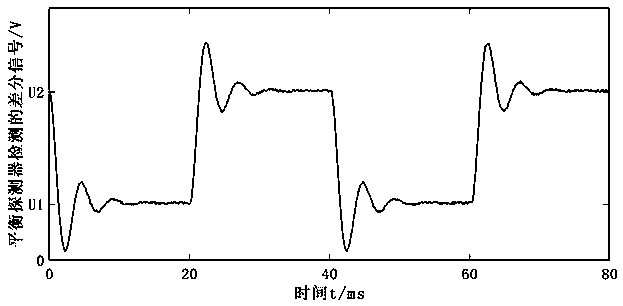

The invention discloses a method and device for measuring dynamic viscosity based on light suspended particles. The method comprises stably capturing particles in a sample to be tested through a capturing beam, applying a modulated beam to the particles in the trapping well, regulating the optical power of the modulated beam by an excitation signal so that the particles carry out response motion after the action of the modulated beam on the particles, acquiring a real-time motion curve of the particles through detecting the optical power change of the scattered light of the captured beam, andcarrying out parameter fitting on the motion curve to obtain resonance frequency and viscous damping so that the dynamic viscosity of the sample to be detected is obtained. The device comprises a sample module, a capture optical trap module, an excitation modulation module and a motion detection module. The method adopts the optical non-contact method to measure the dynamic viscosity of the sample, has a high measurement precision and a fast response speed, and can dynamically detect the dynamic viscosity change of the sample under different temperature and pressure conditions in real time.

Description

technical field [0001] The invention relates to an optical trap measuring device applied in the field of optical engineering, in particular to an optical trap measuring device and a measuring method thereof for precision measurement by using optical suspension. Background technique [0002] Dynamic viscosity is one of the important material properties and technical indicators of fluid. The accurate determination of dynamic viscosity is of great significance in many industrial sectors and scientific research fields, especially in chemical industry, refrigeration, energy and materials industries. For the measurement of low-viscosity fluids, the capillary method, torsional vibration method, falling ball method, rotating cylinder method, etc. are usually used. These methods are difficult to obtain accurate values under high pressure conditions, and it is also difficult to measure the viscosity of gases, the measurement range is narrow, and the measurement accuracy is low. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N11/00

CPCG01N11/00G01N2011/008

Inventor 傅振海李楠李文强胡慧珠舒晓武刘承

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com