Computer liquid cooling source heat dissipation control module

A control module and computer technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problem of unsatisfactory release control of liquid cooling source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

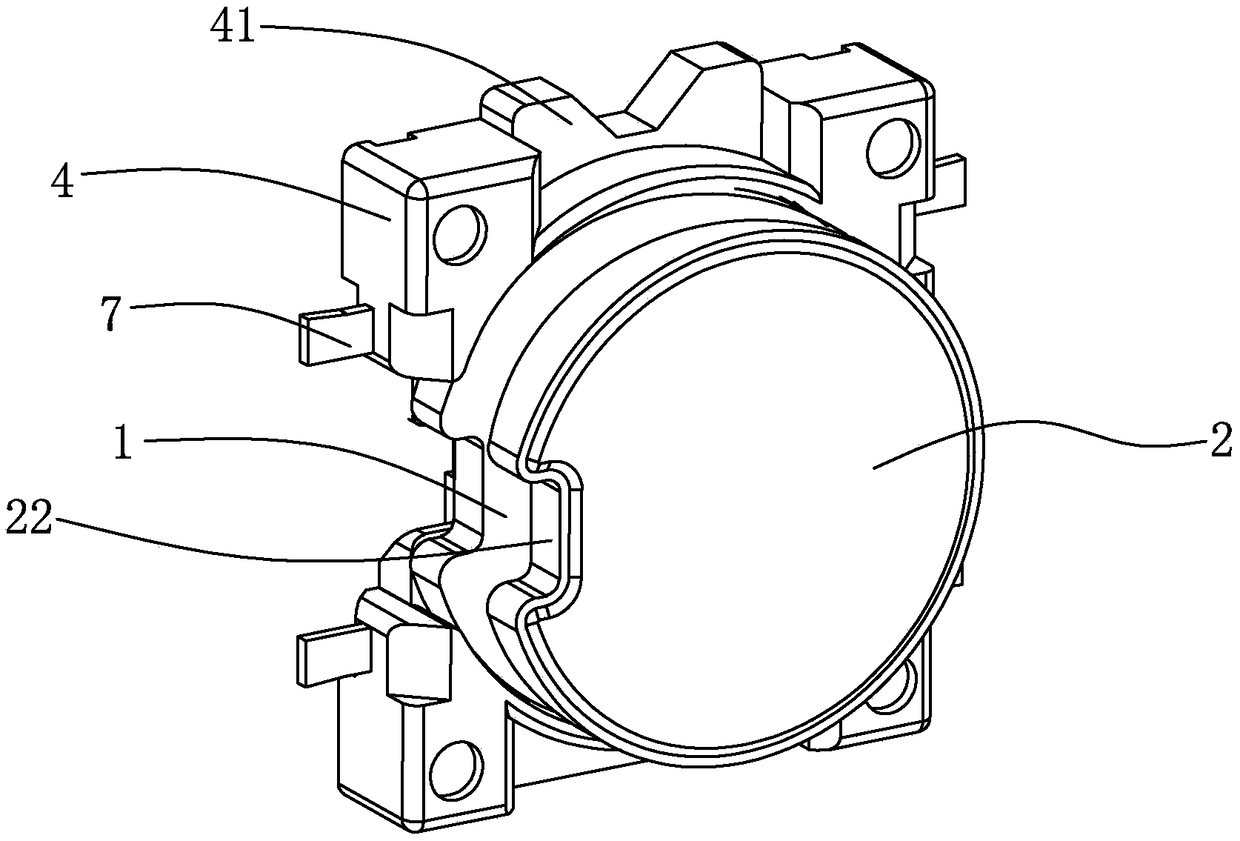

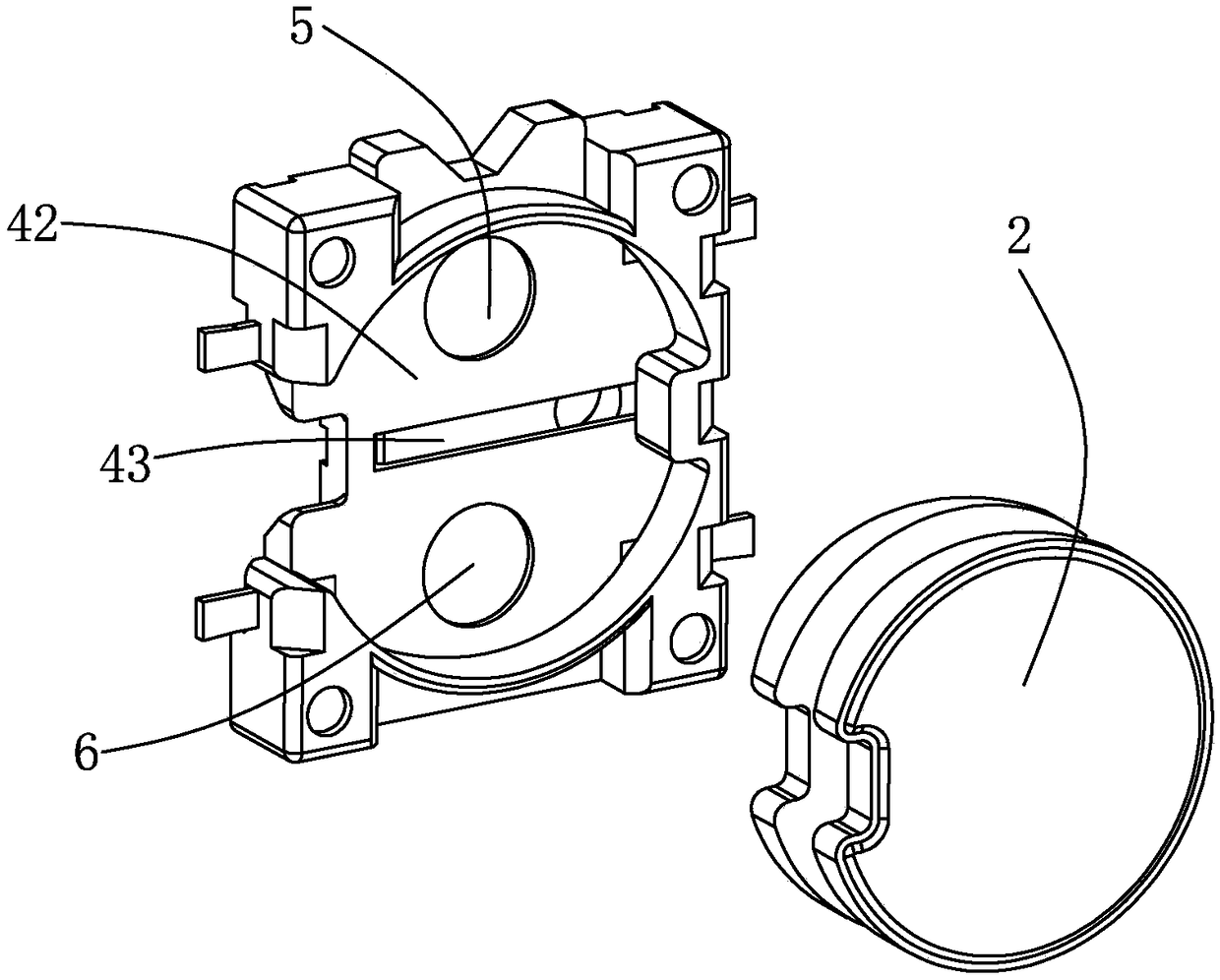

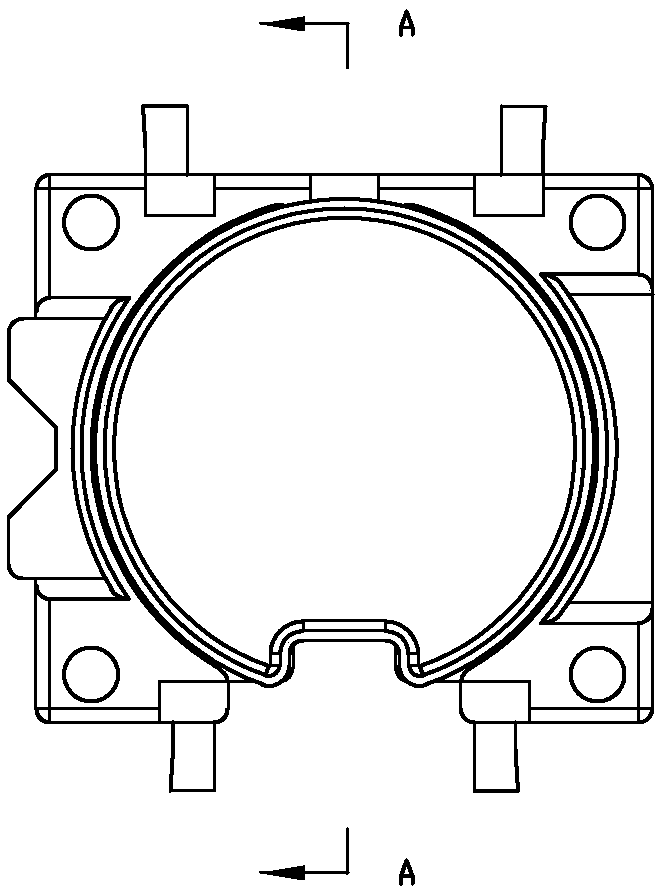

[0023] Embodiment: A heat dissipation control module of a computer liquid cooling source, its main structure includes: valve bottom plate 1, valve top plate 2, iron disc 21, pipe fittings passing through groove 22, air bag column 3, valve base 4, base card slot 41, Valve plate cavity 42, cavity cavity 43, electromagnetic ring a5, electromagnetic ring b6, electrode terminal 7, liquid cooling tube 8, the outer bottom end of the valve base 4 is fixed with a base card slot 41, the valve base 4 is provided with a valve plate inner cavity 42, and the center position of the valve plate inner cavity 42 is provided with a cavity 43, and the left and right sides of the cavity 43 are respectively provided with an electromagnetic ring a5 and an electromagnetic ring b6; a5 and electromagnetic ring b6 are respectively connected to the electrode terminals 7;

[0024] The center position between the valve bottom plate 1 and the valve top plate 2 is clamped and fixed with an airbag column 3, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com