A high-speed continuous large-capacity winding production process for small-sized enameled wire

A production process and enameled wire technology, applied in the field of enameled wire, can solve the problems of inability to meet the high-speed take-up of small-sized enameled wires, the weight of a single axis cannot meet the customer's requirements, and the inability to adapt to the high-speed production of small-sized wires. Center, wall thickness reduction, not easy to eccentric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preferred embodiment of the present invention, a high-speed continuous large-capacity winding production process for small-sized enameled wires, includes the following steps:

[0043] Step S1: Large drawing, stretching the Φ8.0mm~Φ10mm soft low-oxygen copper rod on the large drawing machine for several times, and stretching to a hard copper wire (TY) with a nominal diameter of Φ3.0mm;

[0044] Step S2: medium drawing + annealing, the hard copper wire (TY) obtained in step S1 is stretched on the medium drawing machine for several times, and stretched to a hard copper wire with a nominal diameter of Φ0.80mm~Φ1.00mm ( TY), the copper wire is directly subjected to continuous high-current annealing and winding to obtain a soft copper wire (TR), and the nominal diameter of the soft copper wire (TR) is Φ0.80mm~Φ1.00mm;

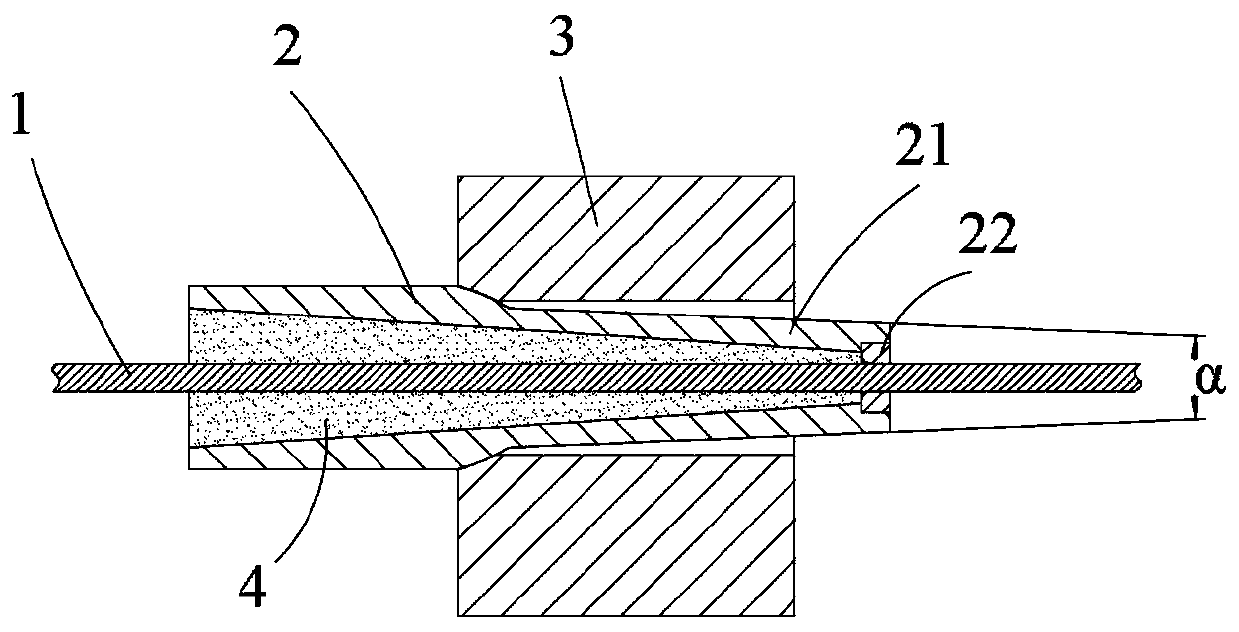

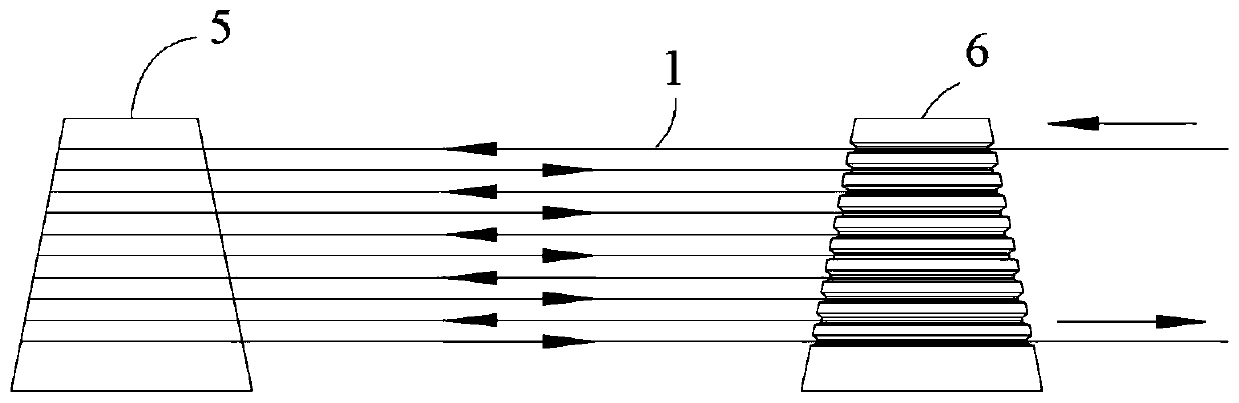

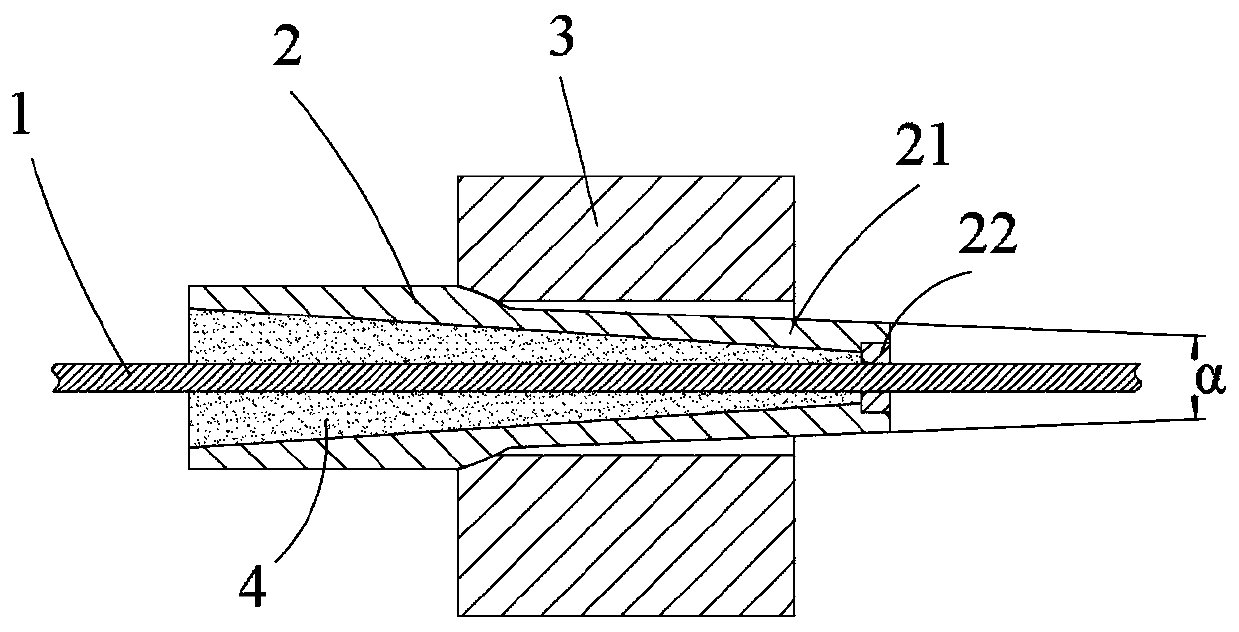

[0045] Step S3: enamelled wire drawing, stretching the soft copper wire (TR) obtained in step S2 on an enamelled wire drawing machine for multiple times, an...

Embodiment 2

[0058] The steps in Example 1 are used to produce enameled wires with a copper conductor diameter of Φ0.15 mm, and the specific steps are as follows.

[0059] Step S1: Large drawing, stretch the Φ8.0mm soft low-oxygen copper rod on the large drawing machine for multiple times (the drawing speed of the large drawing machine is 800m / min), and stretch it to a hard state with a nominal diameter of Φ3.0mm Copper wire (TY);

[0060] Step S2: Intermediate drawing + annealing, stretch the hard copper wire (TY) obtained in step S1 on the intermediate drawing machine for multiple times (the drawing speed of the intermediate drawing machine is 960m / min), and stretch it to a nominal diameter of Φ0 .80mm hard copper wire (TY), and then the hard copper wire (TY) is directly subjected to continuous high-current annealing and take-up (annealing voltage 38V, annealing current 430A, take-up tension 0.20mPa, copper elongation rate 30 %~35%), to obtain a soft copper wire (TR) with a nominal diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com