Novel ceramic plug and electrostatic chuck device having the novel ceramic plug

A ceramic plug, a new type of technology, is used in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc. It can solve problems such as electrostatic chucks and wafer damage, and achieve the effect of preventing arcing and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

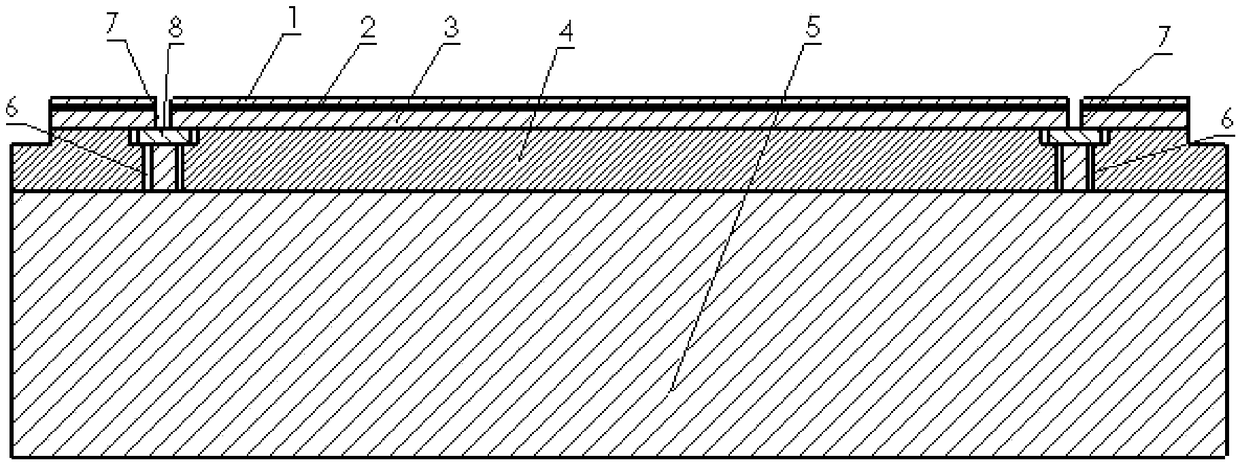

[0019] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

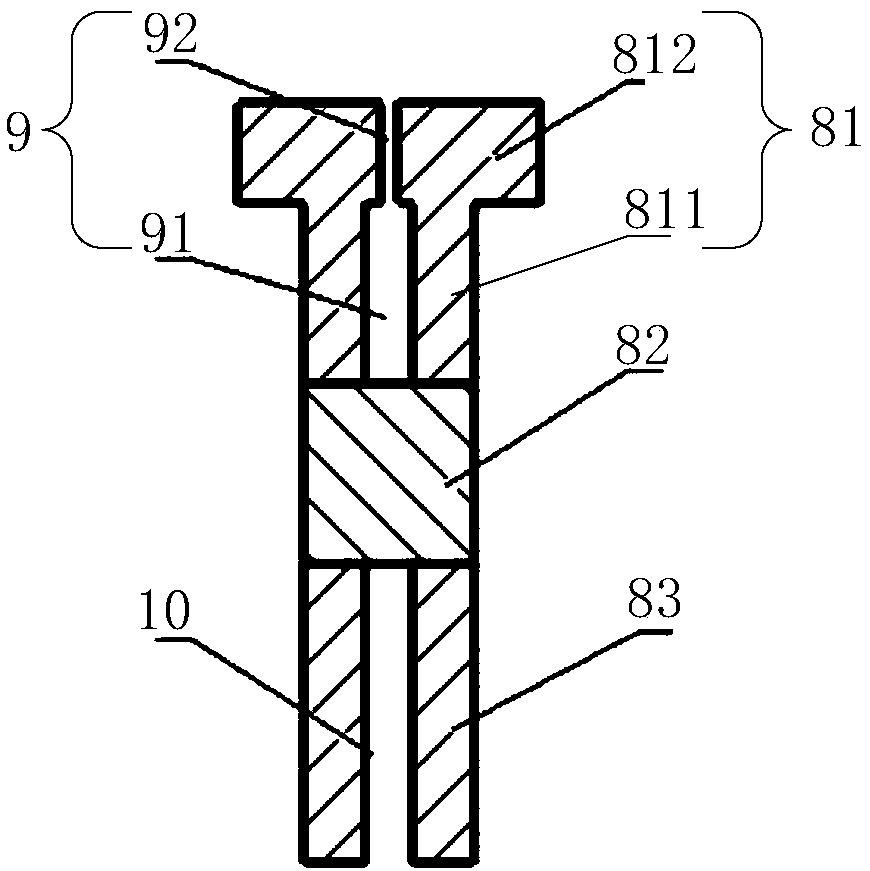

[0020] On the one hand, the present invention provides a kind of novel ceramic plug, such as image 3 As shown, it includes a ceramic plug upper part 81, a porous ceramic column 82 and a ceramic sleeve 83 connected sequentially from top to bottom. The ceramic plug upper part 81 includes a cylindrical part 812 and an annular boss part 811 arranged on the upper part of the cylindrical part 812. A first cooling gas hole 91 is disposed in the middle of the boss portion 811 , a second cooling gas hole 92 is disposed in the middle of the cylindrical portion 812 , and a third cooling gas hole 10 is disposed in the middle of the ceramic sleeve 83 .

[0021] The novel ceramic plug of the present invention includes the upper part of the ceramic plug, the porous ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com