Resistance-type high-temperature superconducting fault current limiter

A fault current limiter, high-temperature superconducting technology, applied in the usage of superconductor elements, emergency protection circuit devices for limiting overcurrent/overvoltage, electrical components, etc., can solve the problem of burning out superconducting strips, destructive Strong and easy to damage the insulation performance of the winding system, etc., to improve the fault current limiting capability, ensure safety and stability, improve heat dissipation effect and electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

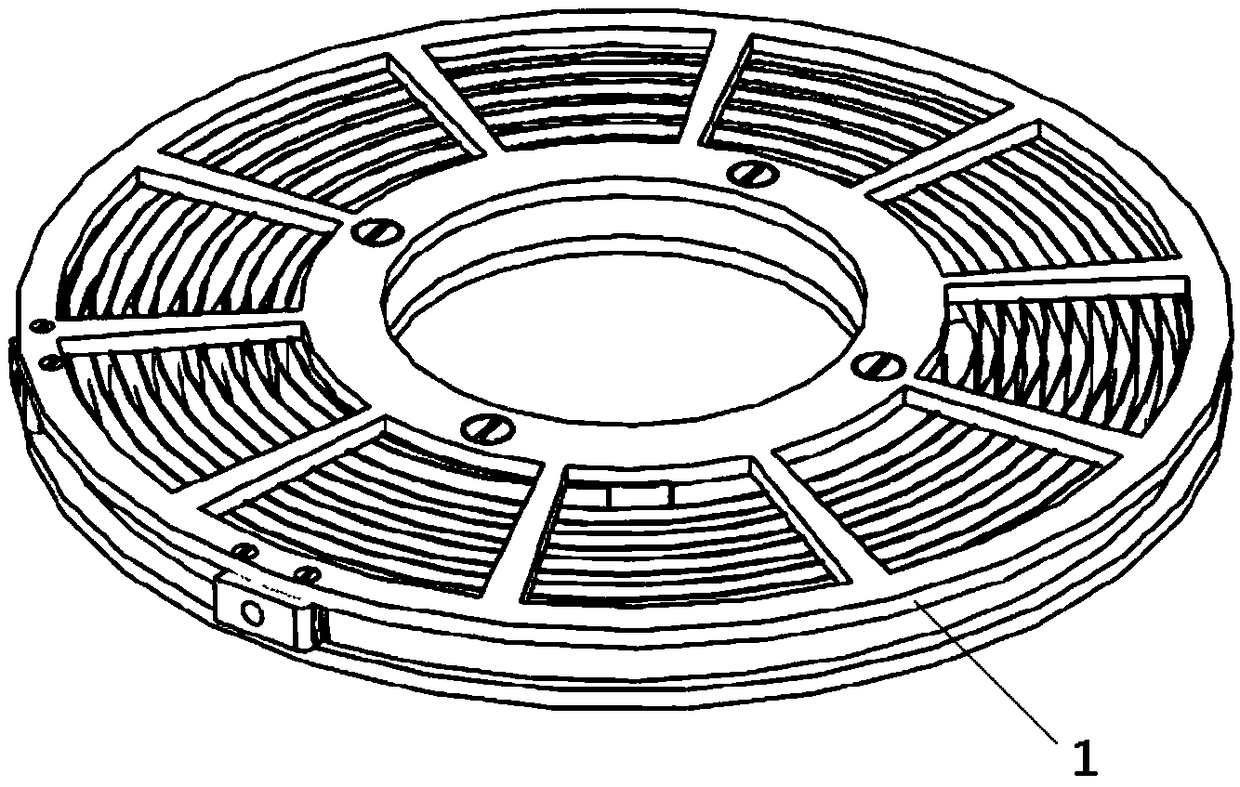

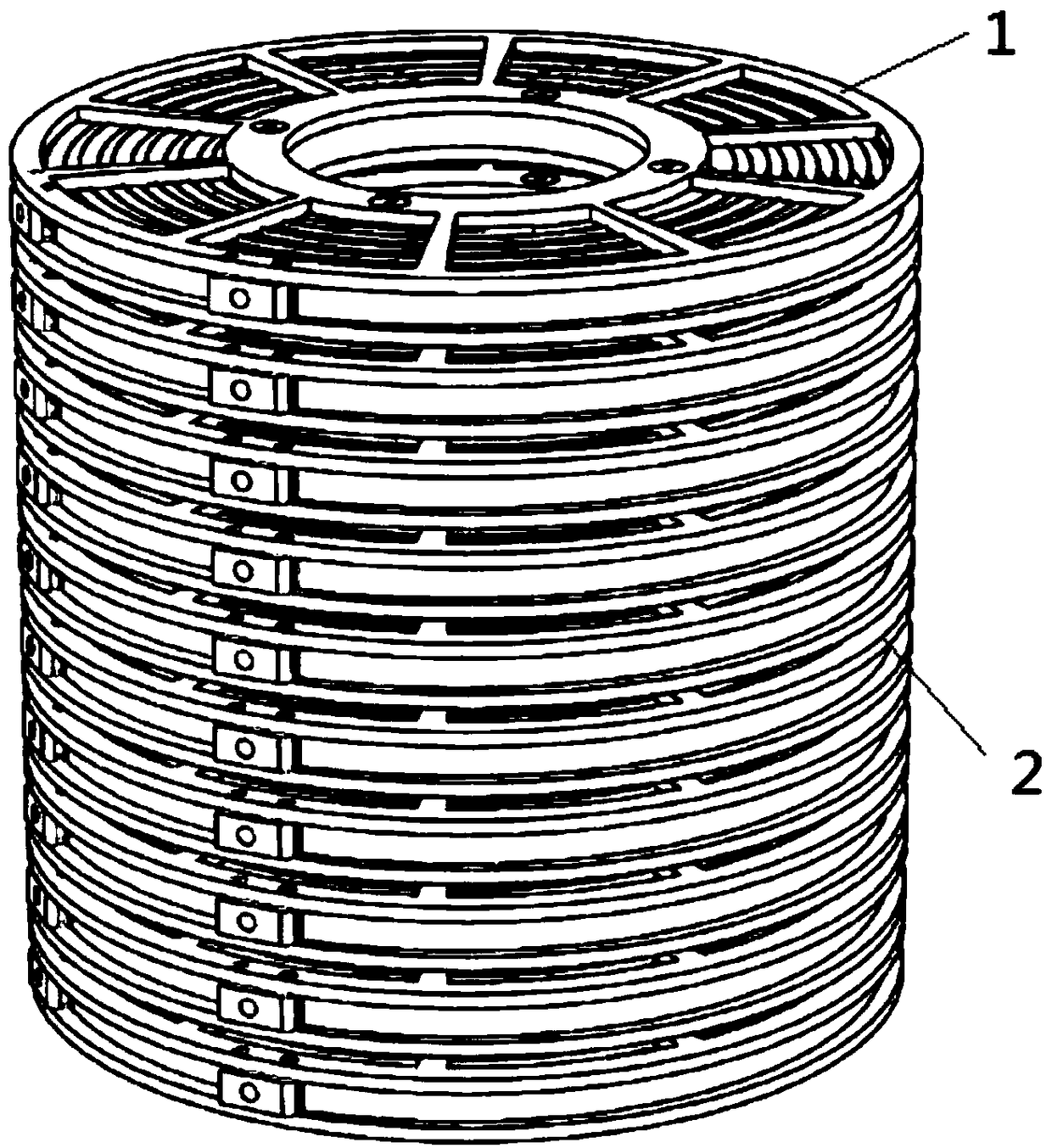

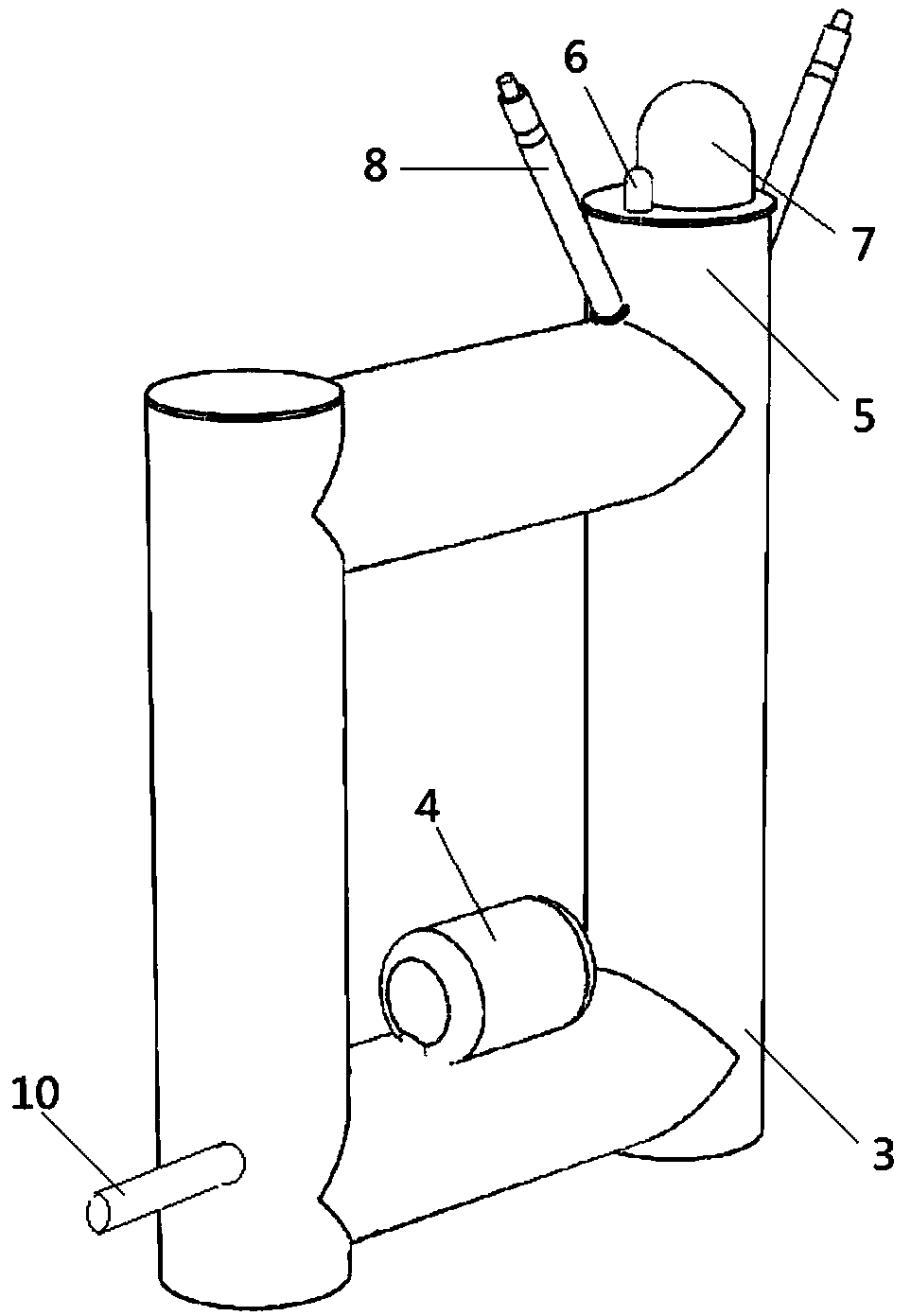

[0016] The invention mainly includes superconducting non-inductive winding 2, liquid nitrogen circulation container 3, liquid nitrogen pump 4, gas chamber 5, small vent valve 6, large vent valve 7, current lead wire 8, liquid replenishment port 10 and other components. The liquid nitrogen pump 4 is installed at the bottom of the liquid nitrogen circulation container 3, and the two form a low-temperature refrigerant—the circulating cooling assembly of liquid nitrogen. The small vent valve 6 and the large vent valve 7 are installed side by side on the end plate at the top of the liquid nitrogen circulation container 3 , both are pressure regulation and control accessories during liquid nitrogen operation; one end of the superconducting non-inductive winding 2 and the current lead 8 are installed in the liquid nitrogen circulation container 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com