Fabrication integral machine of sliding table wrinkled PCB electronic device

An electronic device and wrinkle technology, applied in the direction of electrical components, printed circuit manufacturing, assembling printed circuits with electrical components, etc., can solve the problems that affect the quality and reliability of wrinkled PCB, the process performance is not uniform, and it is not suitable for mass production, etc. Achieve the effect of ensuring quality and reliability, good stretchability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

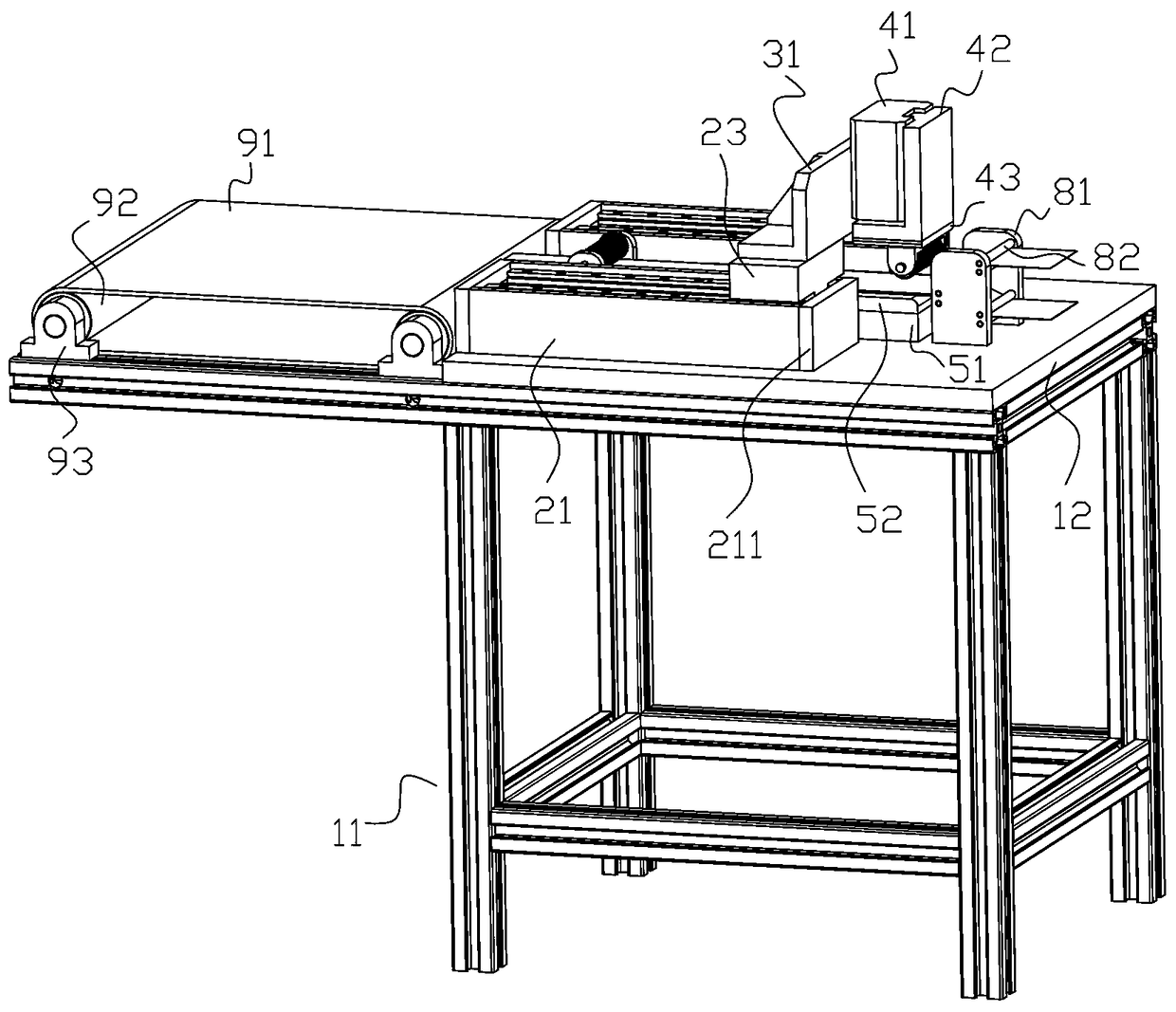

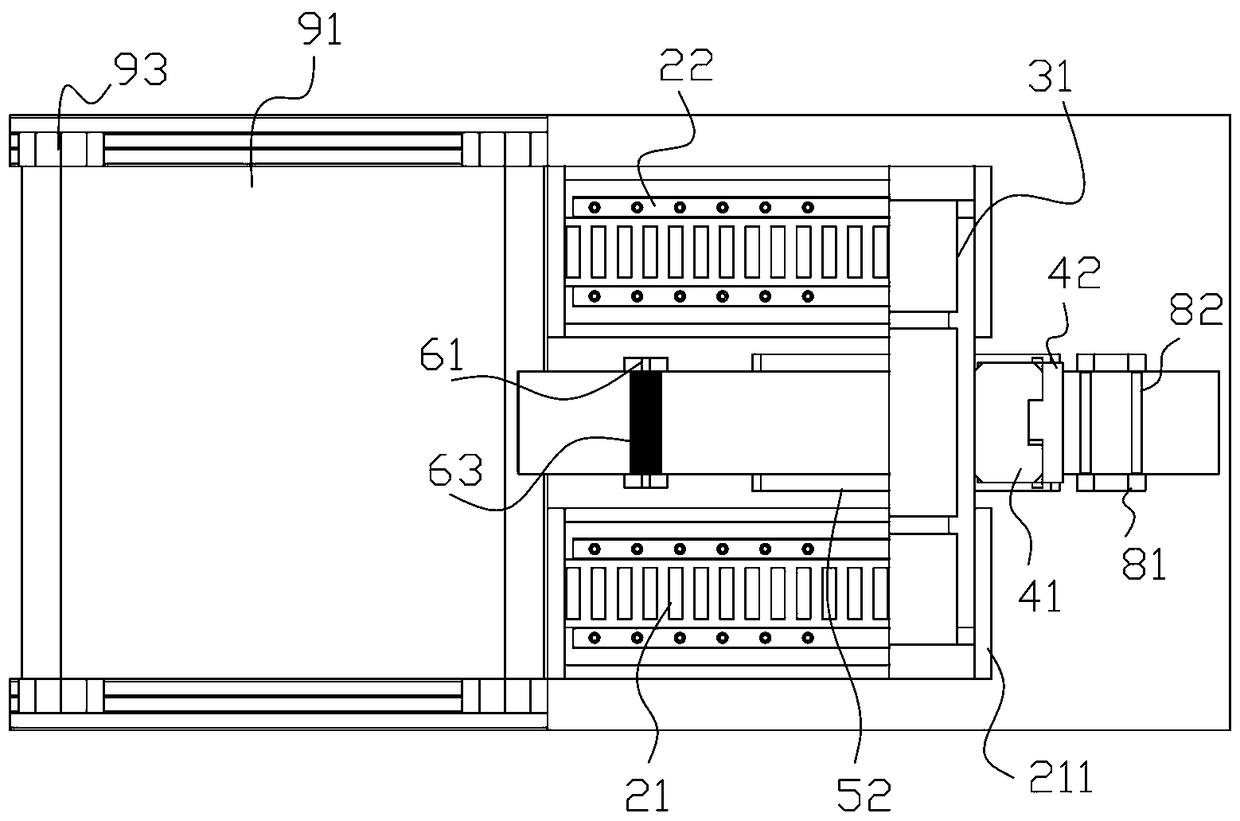

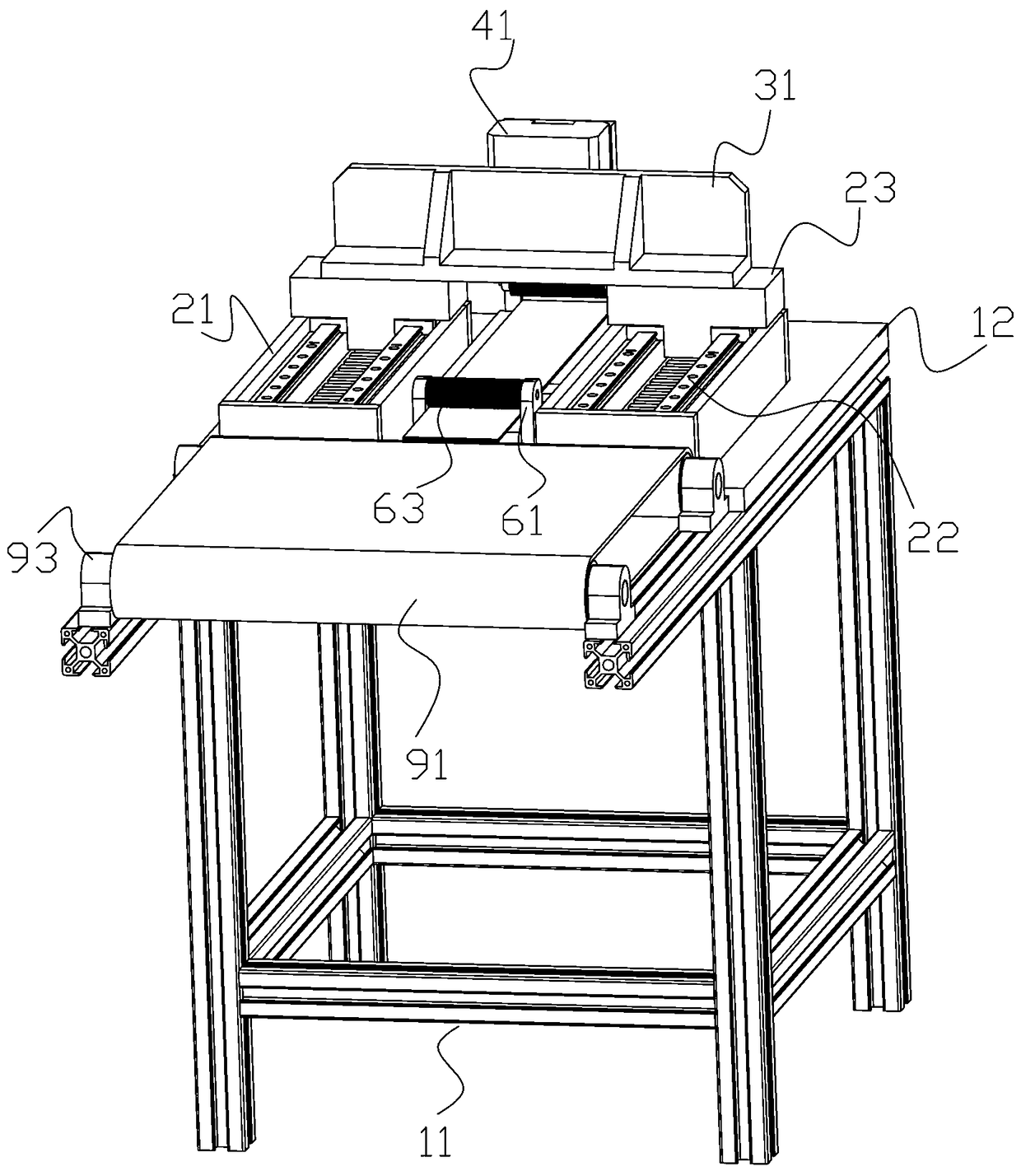

[0027] Such as Figure 1 to Figure 7 As shown, a complete machine for preparing slide folded PCB electronic devices described in this embodiment includes a bracket 11, and a first backing plate 12 is installed at one end of the bracket 11;

[0028] Two sliding mechanisms are arranged side by side on the first backing plate 12, each of the sliding mechanisms includes a linear motor box 21, and two linear guide rails 22 are arranged side by side on the linear motor box 21, and a T-shaped An electric moving block 23, the bottom surfaces of the two ends of the cross arm of the electric moving block 23 are respectively provided with sliders 24, and the sliding blocks 24 are slidably connected with the linear guide rail 22;

[0029] It also includes a ""-shaped b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap