Bread making method and bread machine

A production method and bread machine technology, which is applied in the direction of roasters/barbecue grids, kitchen utensils, household utensils, etc., can solve the problems of insufficient flavor and rough taste of finished bread, achieve soft taste, mellow taste, and prolong fermentation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

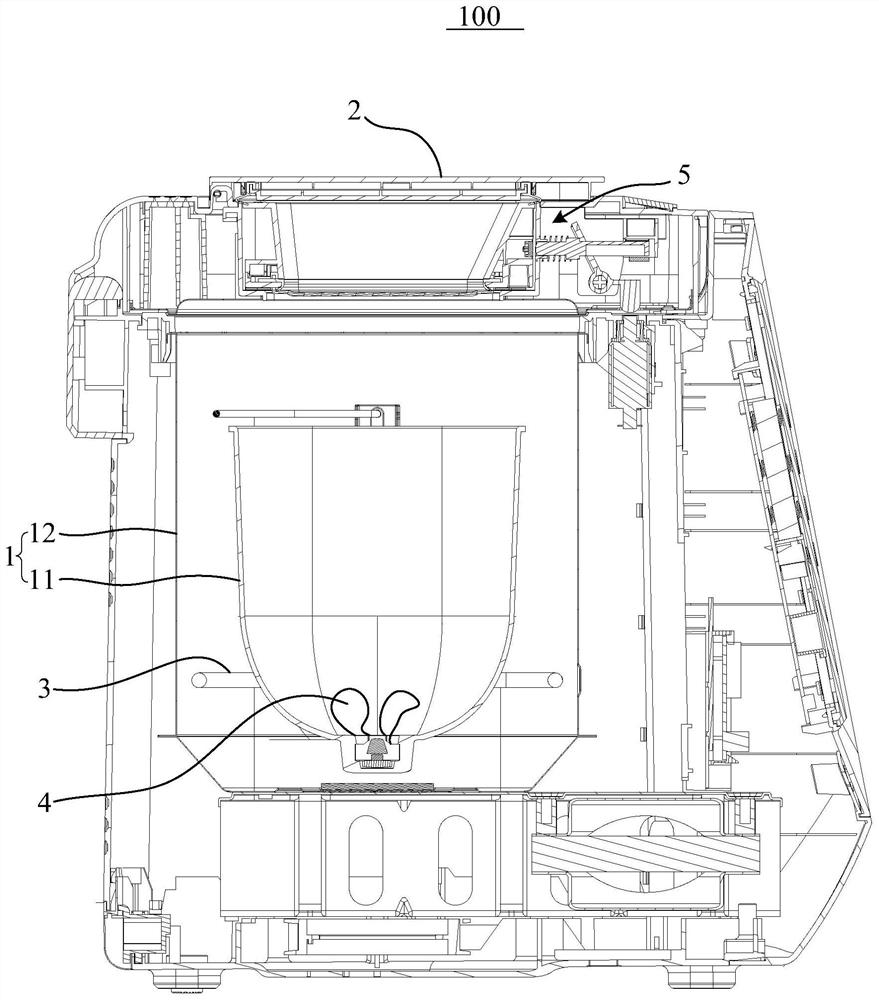

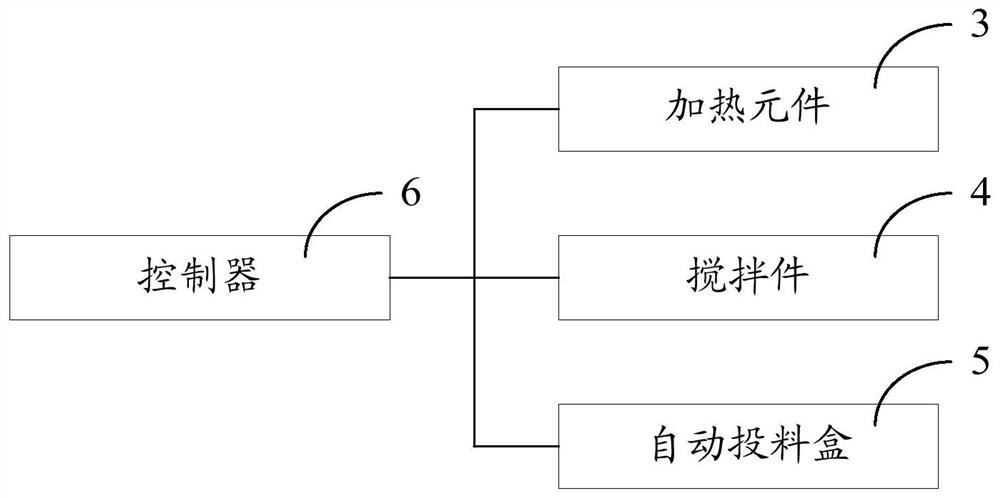

[0036] A kind of bread making method provided by the present invention, in order to achieve the above object, a kind of bread making method provided by the present invention is applied to bread machine, refer to figure 1 , figure 1 It is a schematic structural view of the bread machine used in the bread making method of the present invention; the bread machine 100 includes a housing 1, an automatic feeding box 5 and an upper cover 2 that is closed on the housing 1, and the housing 1 is composed of A bread bucket 11 and an oven bucket 12 are arranged in sequence from inside to outside, the bread bucket 11 is provided with a stirring member 4 , and the oven bucket 12 is provided with a heating element 3 .

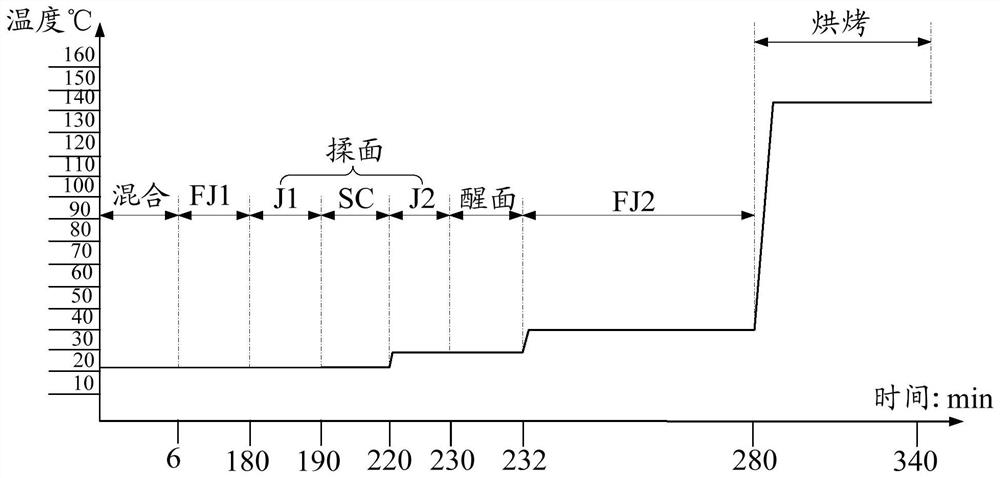

[0037] refer to figure 2 , figure 2 It is a heating curve diagram of an embodiment of the bread machine 100 u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com