Drying method for camellia seeds

A drying method and technology of camellia oleifera seeds, which are applied in the directions of drying solid materials, heating to dry solid materials, and promoting the drying of solid materials, can solve the problems of sticky and sour appearance of camellia oleifera seeds, and achieve oil quality improvement, The effect of excellent product quality and excellent process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

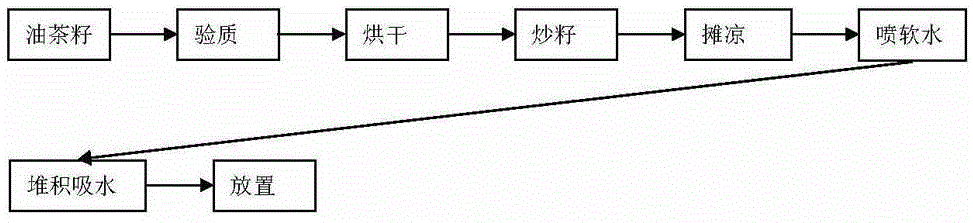

Method used

Image

Examples

Embodiment 1

[0030] Put the to-be-dried camellia seeds peeled off the husks into the continuous vertical dryer for pre-dehydration, the heating time is 11min, the hot air temperature is 109°C, the pre-dehydration time is 22min, and the thickness of the material layer is 38cm; after pre-dehydration Camellia oleifera seeds enter the second and third layers of drying section, and are dried by medium temperature process. The temperature of hot air in the drying section is 82°C, the drying time of each layer is 40min, and the thickness of the material layer is 62cm; after medium temperature drying The raw materials are dried in the drying section of the conventional process. After drying, they are initially cooled by the drying tower and then transported to the warehouse for cooling. The thickness of the cooling is 10cm, and the cooling time is 24 hours.

Embodiment 2

[0032] Put the to-be-dried camellia seeds peeled off the husks into the continuous vertical dryer for pre-dehydration, the heating time is 10min, the hot air temperature is 110°C, the pre-dehydration time is 20min, and the thickness of the material layer is 40cm; after pre-dehydration Camellia oleifera seeds enter the second and third layers of drying section, and are dried by medium temperature process. The temperature of hot air in the drying section is 80°C, the drying time of each layer is 40min, and the thickness of the material layer is 60cm; after medium temperature drying The raw materials are dried in the drying section of the conventional process. After drying, they are initially cooled by the drying tower and then transported to the warehouse for cooling. The thickness of the cooling is 10cm, and the cooling time is 24 hours.

Embodiment 3

[0034] The camellia seeds to be dried after peeling off the husks are put into a continuous vertical dryer for pre-dehydration. The heating time is 9 minutes, the temperature of the hot air is 111°C, the pre-dehydration time is 18 minutes, and the thickness of the material layer is 42cm; Camellia oleifera seeds enter the second and third layers of drying section and are dried by medium temperature process. The temperature of the hot air in the drying section is 78°C, the drying time of each layer is 40min, and the thickness of the material layer is 58cm; after medium temperature drying The raw materials are dried in the drying section of the conventional process. After drying, they are initially cooled by the drying tower and then transported to the warehouse for cooling. The thickness of the cooling is 10cm, and the cooling time is 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com