Ultrasonic treatment technology of honey

A processing technology and ultrasonic technology, applied in the direction of food ultrasonic treatment, food science, etc., can solve the problems of broken walls and broken, and achieve the effect of nutritional balance, easy absorption, and improved honey taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

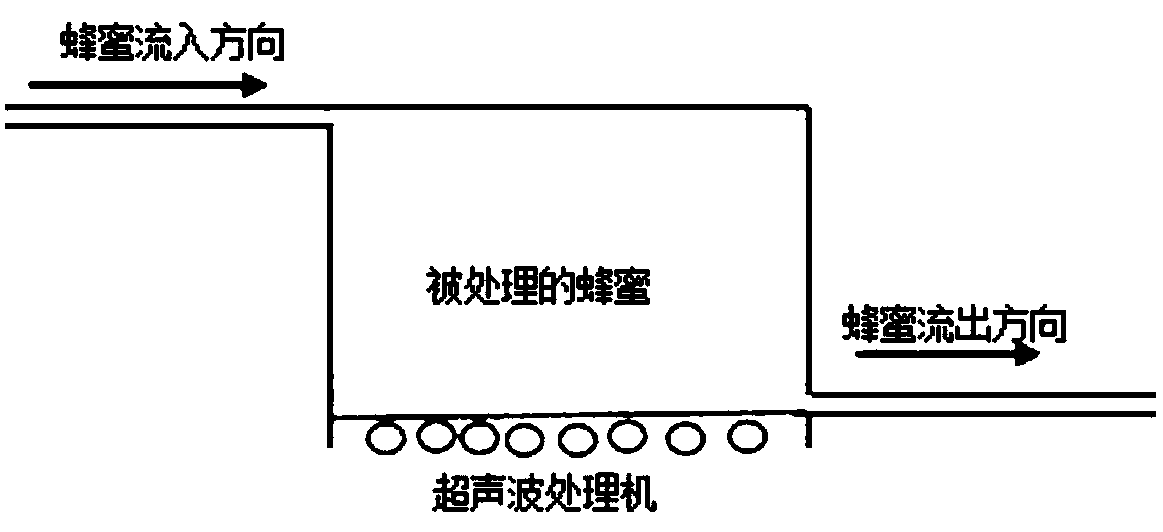

[0047] Ultrasonic cleaning machine-like ultrasonic treatment container is designed as: ultrasonic frequency 20kHz, power 300-600w, each ultrasonic vibrator 100 watts, six 100w vibrators arranged in a straight line, installed at the bottom of the treatment tank, treatment tank size: 450mm long * 100mm wide * 300mm high. Process about 10kg of liquid honey at a time. The power selection is 600W, and the processing time is 6min.

[0048] In the experimental study of eliminating Saccharophilus yeast, set 20kHz frequency, 600w power, and study different processing time. With the prolongation of processing time, the results are as follows Figure 5 processing results.

[0049] Figure 5 Foam generation at different ultrasonic treatment times. The processing time from left to right is: 0, 1, 1, 3, 3, 5, 5, 7, 7min processing time. Repeated numbers are set repeats.

[0050] Figure 5 What the experiment chooses is that Baume degree is 39 degrees and already has partly fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com