Method for hydrolyzing vegetable fibre by solid acid

A plant fiber and solid acid technology, which is applied in sugar production, food science, sugar production, etc., can solve the problems of high corrosion resistance requirements for equipment, high cost of enzyme preparations, loss of concentrated acid in catalysts, etc., and overcome economical problems. Low efficiency, low corrosion requirements, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

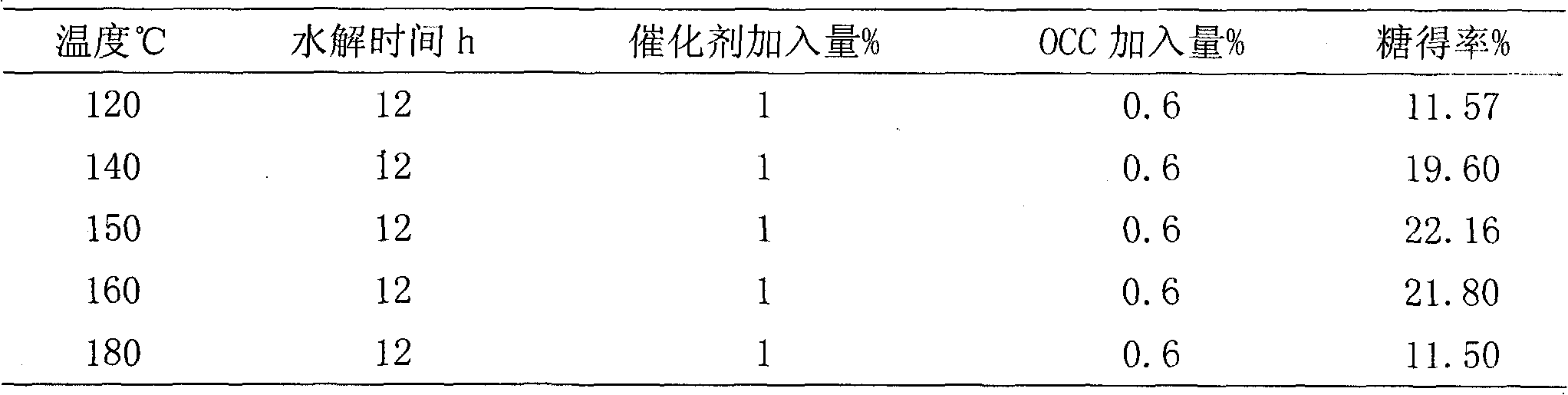

[0020] OCC fragments and carbon-based sulfonic acid catalysts were added to water for miscibility according to the mass percentage of water (as shown in Table 1), and reacted at different temperatures for 12 hours. The hydrolyzate is filtered, part of the resulting filtrate is used for sugar production analysis, part of it is used as a fermentation substrate, and the filter residue is used for recycling.

[0021] Table 1 Comparison of the hydrolysis effect of carbon-based solid sulfonic acid on OCC at different temperatures

[0022]

[0023] Table 2 Effect of reuse times on hydrolysis effect

[0024]

[0025] As can be seen from Table 1, with the change of temperature, the sugar yield increases first and then decreases. When the temperature is 150°C, the sugar yield reaches a maximum value of 22.16%, which is comparable to that of traditional dilute sulfuric acid hydrolysis (the maximum sugar yield is 25%). The comparison is very close; when the temperature is 180°C, th...

Embodiment 2

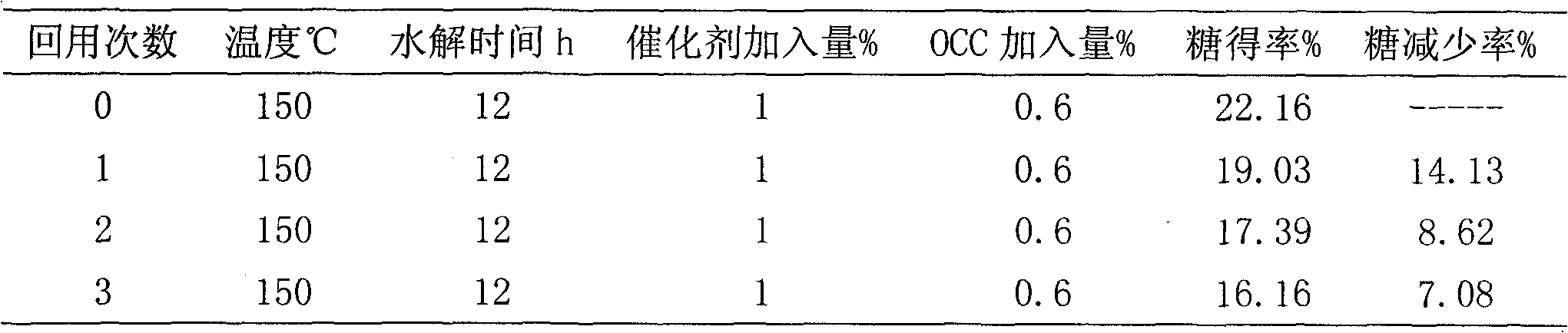

[0027] OCC fragments and carbon-based sulfonic acid catalysts were added to water for miscibility according to the mass percentage of water (as shown in Table 3), and reacted at 150° C. for different times. The hydrolyzate is filtered, part of the obtained filtrate is used for sugar production analysis, part is used for the fermentation of the hydrolyzate, and the filter residue is used for recycling.

[0028] Table 3 Comparison of the hydrolysis effect of carbon-based solid sulfonic acid on OCC at different times

[0029]

[0030] Table 4 Effect of reuse times on hydrolysis effect

[0031]

[0032] It can be seen from Table 3 that with the change of time, the sugar yield increased first and then decreased. At 8 hours, the sugar yield reached a maximum of 24.07%, and then from 8 to 12 hours, the sugar yield decreased by 7.61%. , indicating that in a mild hydrothermal environment, the catalyst has a high selectivity for sugar, and the sugar is further converted into by-p...

Embodiment 3

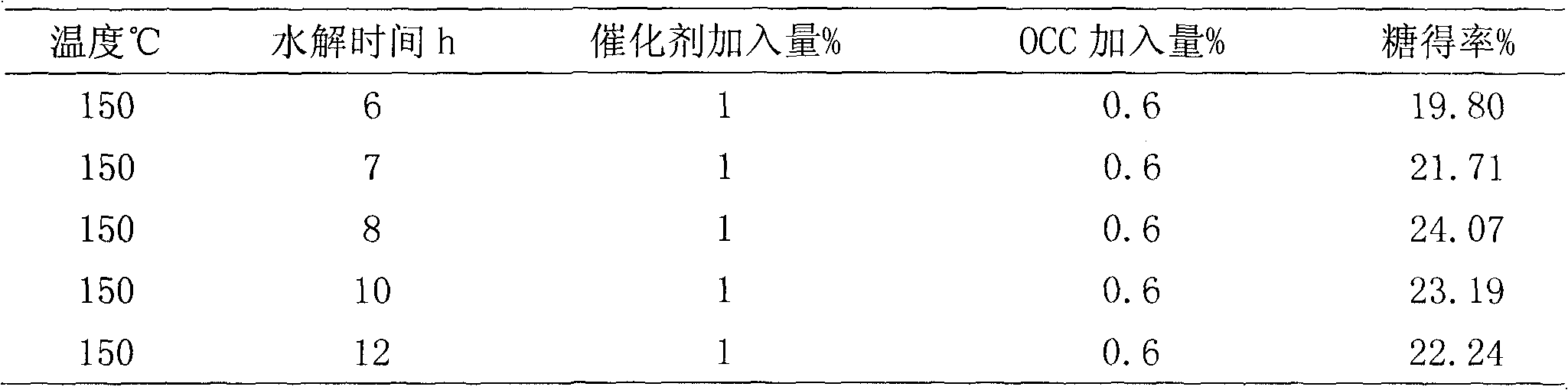

[0034] OCC fragments were added to water for miscibility according to the mass percentage of water (as shown in Table 5), carbon-based solid sulfonic acid catalysts were added to water for miscibility according to different concentrations, and reacted at 150°C for 8 hours. The hydrolyzate is filtered, part of the obtained filtrate is used for sugar production analysis, part is used for the fermentation of the hydrolyzate, and the filter residue is used for recycling.

[0035] Table 5 Comparison of the hydrolysis effects of different concentrations of carbon-based solid sulfonic acid on OCC

[0036]

[0037] Table 6 Effect of reuse times of different carbon-based solid sulfonic acid on hydrolysis effect

[0038]

[0039] It can be seen from Table 5 that with the change of the amount of catalyst added, the sugar yield increased first and then decreased. When the amount of catalyst added was 1.2%, the sugar yield reached a maximum value of 26.44%. The decrease in yield was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com