A control method for an injection molding machine

A control method and molding machine technology, applied in the field of injection molding machine control, can solve problems such as inconsistency in mold weight, inability to achieve effective and accurate production operations of injection molding machines, and imperfections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

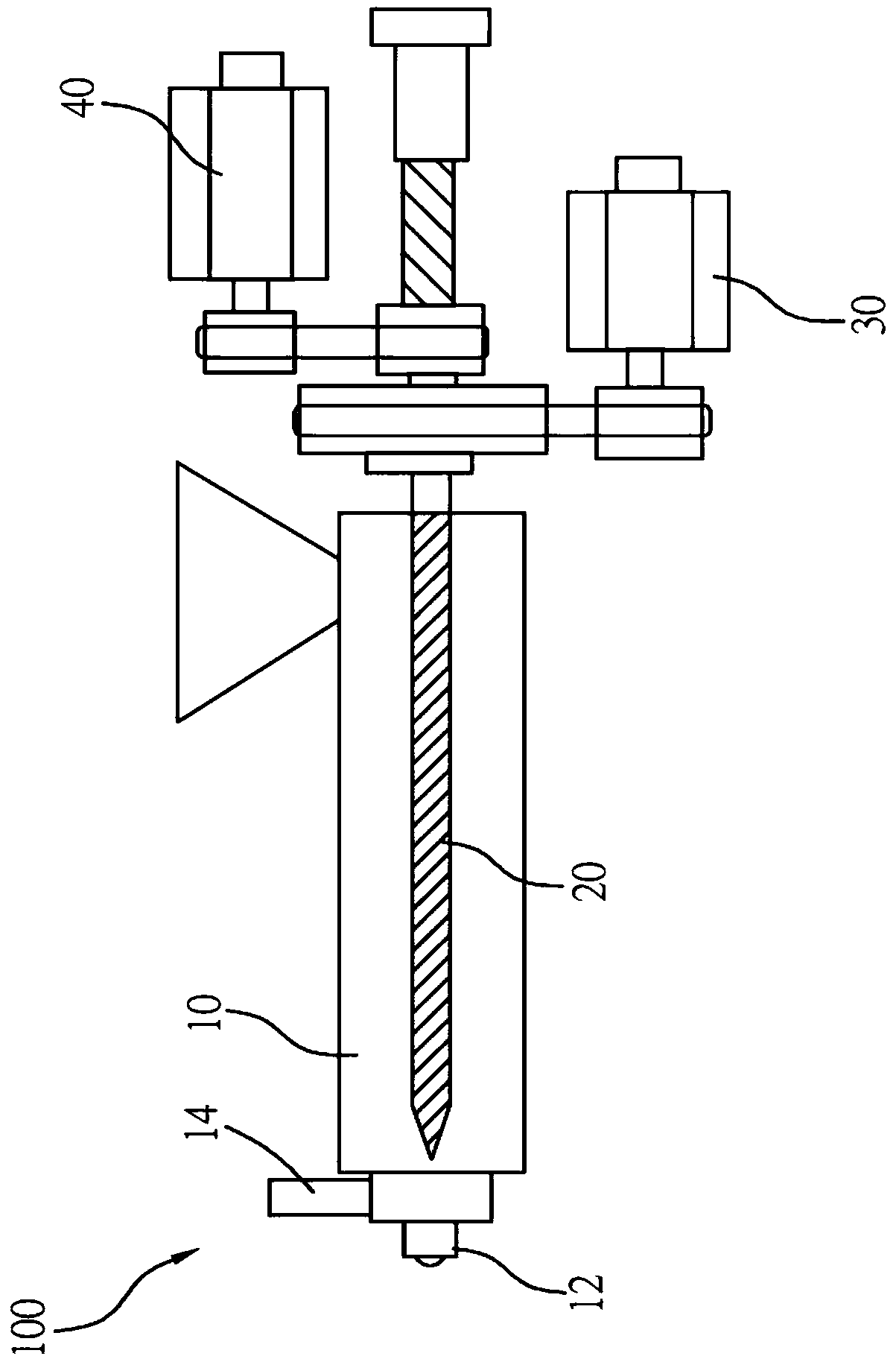

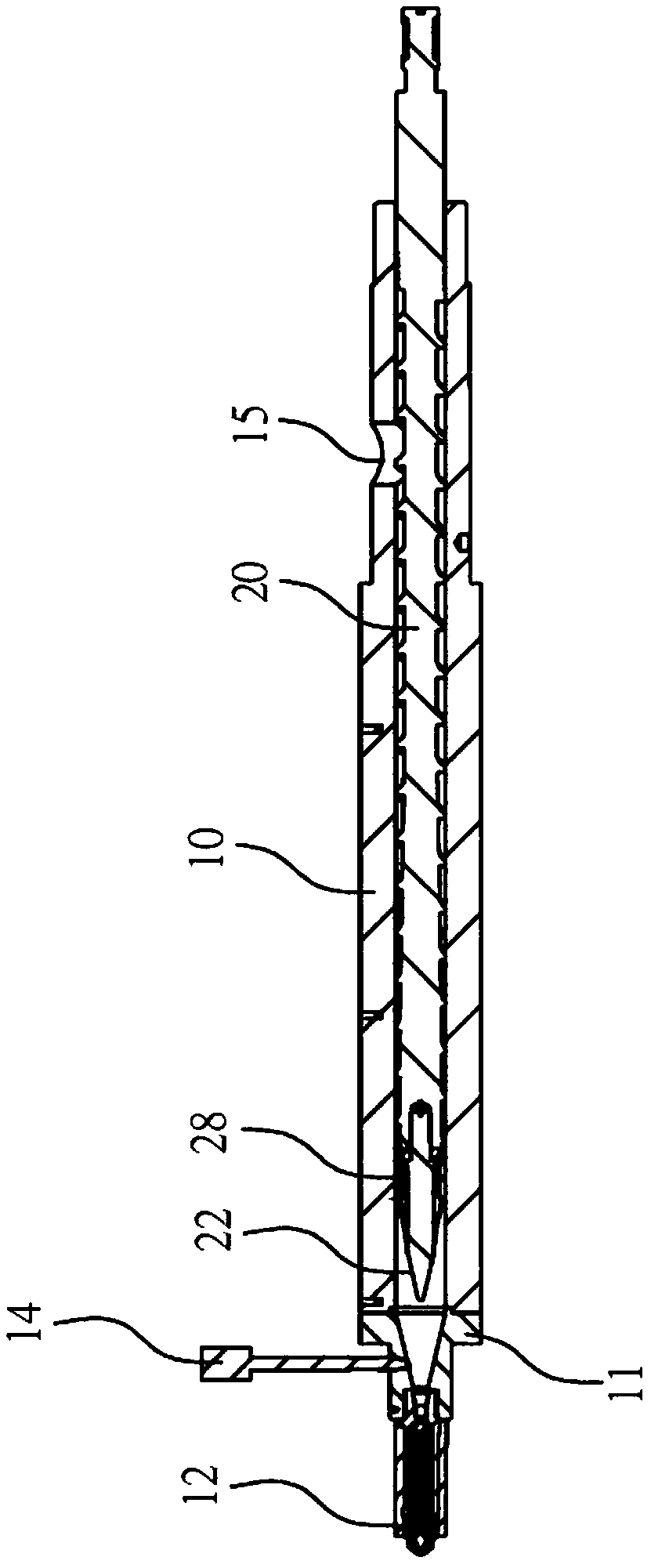

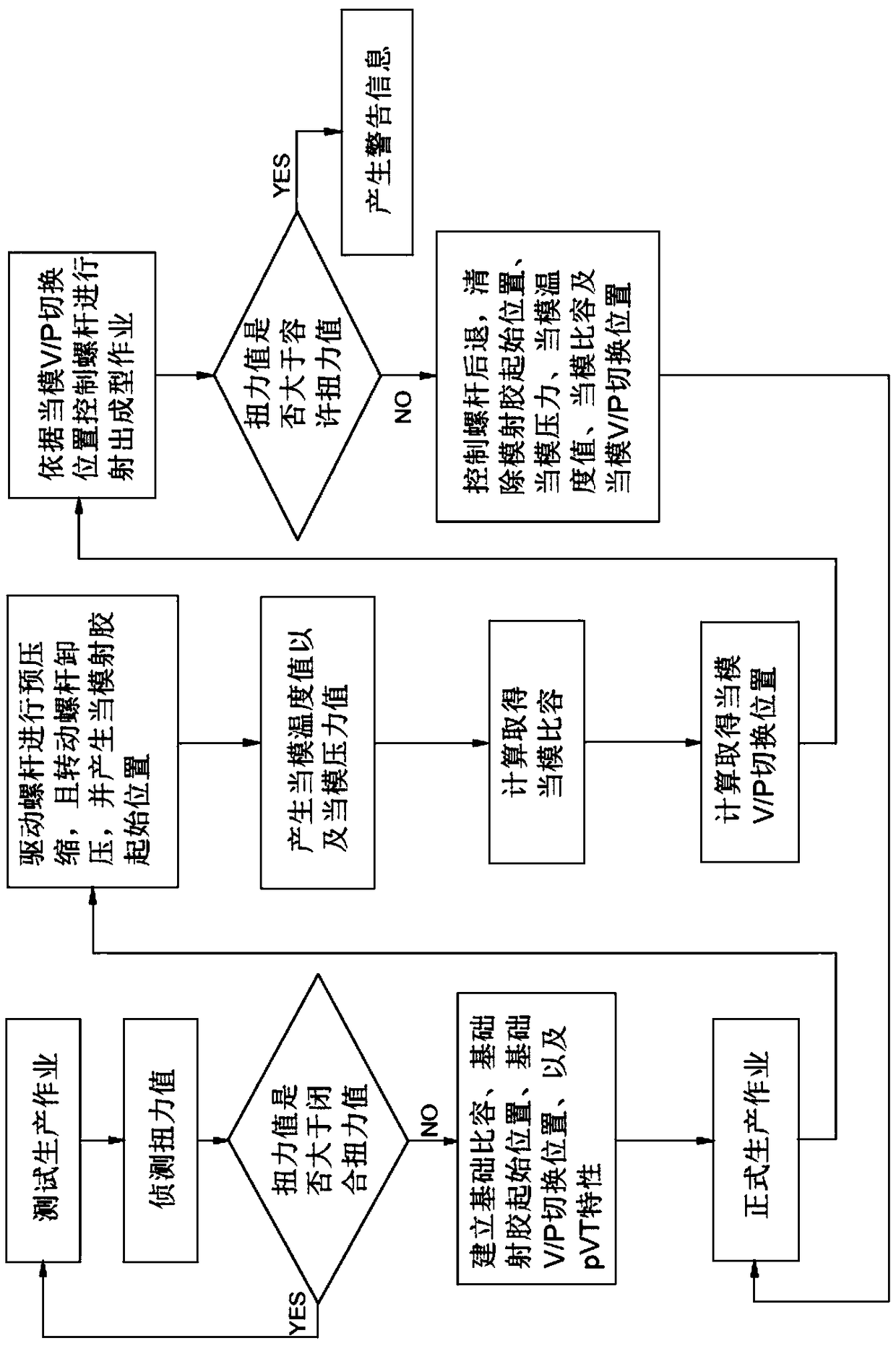

[0031] In order to illustrate the present invention more clearly, a preferred embodiment is given and described in detail with reference to the drawings. See figure 1 As shown, the control method of the present invention is used to apply to an injection molding machine 100. In this embodiment, a screw type injection molding machine is taken as an example, but it is not limited thereto. The injection molding machine 100 includes a material tube 10 , a feeding motor 30 and an injection motor 40 . continued figure 2 , the material pipe 10 has a material port 15 for inputting plastic, the front end of the material pipe 10 has a nozzle flange 11 connected to a nozzle 12, and the nozzle 12 is connected to a mold (not shown), and the The material tube 10 is provided with a pressure thermometer 14 near the nozzle 12 to measure the pressure and temperature in the material tube 10 close to the nozzle 12 (that is, the material storage area in the material tube 10 for storing melt glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com