Pulling rope tensioning device of hollow glass with built-in shutter

A technology of tensioning device and traction rope, applied in the direction of door/window protection device, window/door, building components, etc., can solve the elongation of traction rope, affecting the lifting effect of venetian blinds, and the effect of venetian blinds lifting and lowering. and other problems to achieve the effect of ensuring the lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

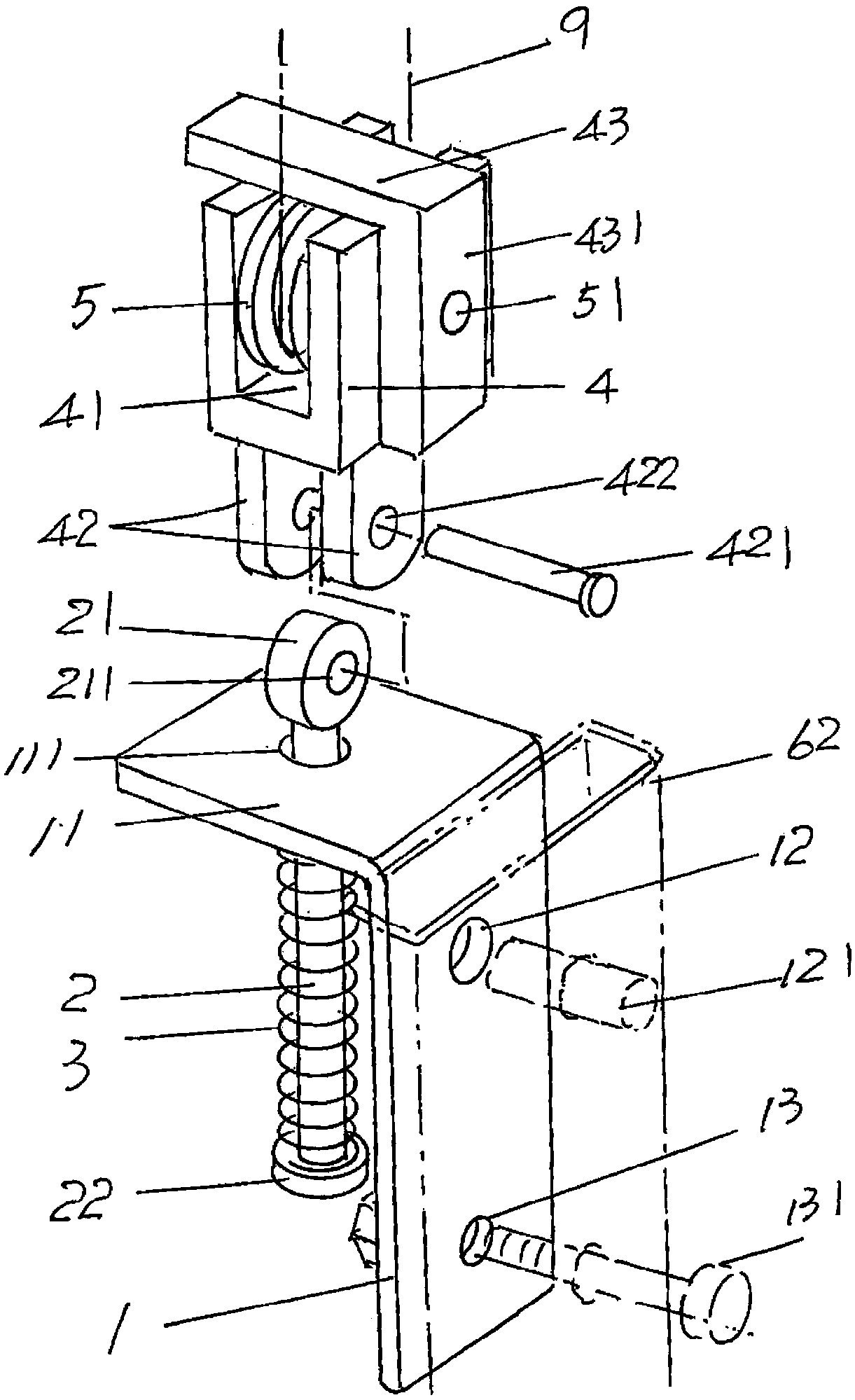

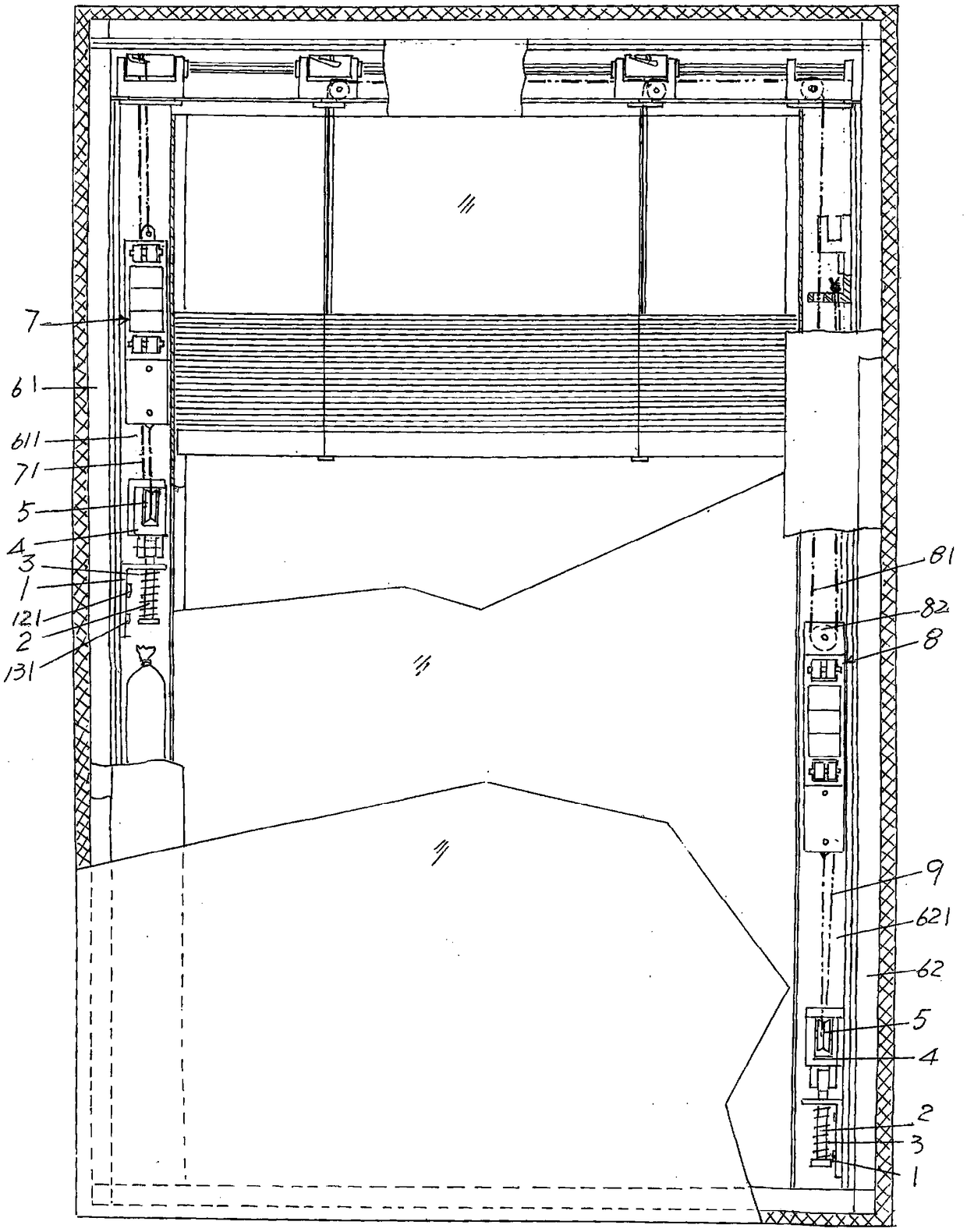

[0012] See figure 1 , showing a spring rod seat 1, a spring rod seat folded plate 11 is horizontally folded on the upper end of the spring rod seat 1, and a spring rod hole 111 is provided on the spring rod seat folded plate 11, by figure 1 As shown, the shape of the aforementioned spring rod seat 1 is an inverted L-shape; a spring rod 2 is shown, which is inserted into the aforementioned spring rod hole 111 floating up and down, and a spring rod 21 is formed at the upper end thereof. Spring rod connector 21, this spring rod connector 21 is positioned at the top of spring rod seat folded plate 11, and offers a spring rod connector hole 211, is formed with spring support seat 22 at the lower end of spring rod 2; Tighten the spring 3, the tension spring 3 is sleeved on the spring rod 2, and the upper end of the tension spring 3 is supported on the downward side of the spring rod seat folding plate 11, and the lower end of the tension spring 3 is supported on the spring support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com