Control clamp used on automobile

A fixture and automobile technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, metal processing, etc., can solve the problems of different required angles, flipping fixtures that cannot adapt to changes in the crowd, time-consuming and labor-intensive problems, etc., to improve efficiency, facilitate operation, and light use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

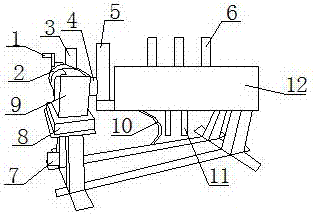

[0016] This program is implemented in this way, please refer to figure 1 , this scheme is implemented as follows, and the functions of each component are introduced:

[0017] Control valve 1 (three-position, four-way manual control valve): it is a three-position, four-way valve with three gears, left, middle, and right. When the handle of the control valve is turned to the left gear, the left air pipe leads to the intake air, driving the pneumatic When the motor 3 is running, when the handle of the control valve is turned to the right gear, the air pipe on the right is connected to the intake air, driving the air motor 3 to run in the reverse direction; Ventilation, the gas is enclosed in the air motor 3, and the turbine stops running;

[0018] Gear transmission box 2: transmits the power brought by the air motor 3 to ensure that the clamp body 12 has power when it rotates;

[0019] Pneumatic motor 3: power device, driven by airflow to rotate;

[0020] Transmission shaft 4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com