A plugger for coiled tubing operation

A plug-and-operate technology, applied in wellbore/well components, sealing/packaging, earth-moving drilling, etc., can solve the problems of inaccurate positioning, single use of plugs, small application range, etc., to increase practicability, accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

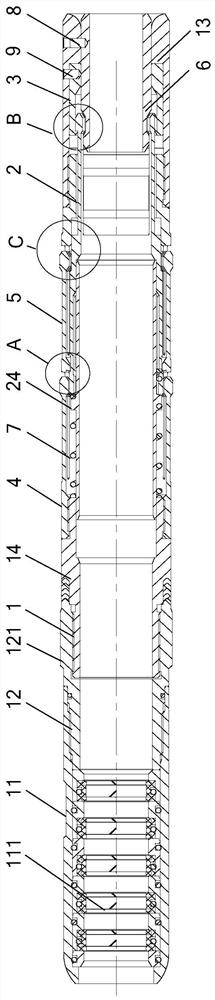

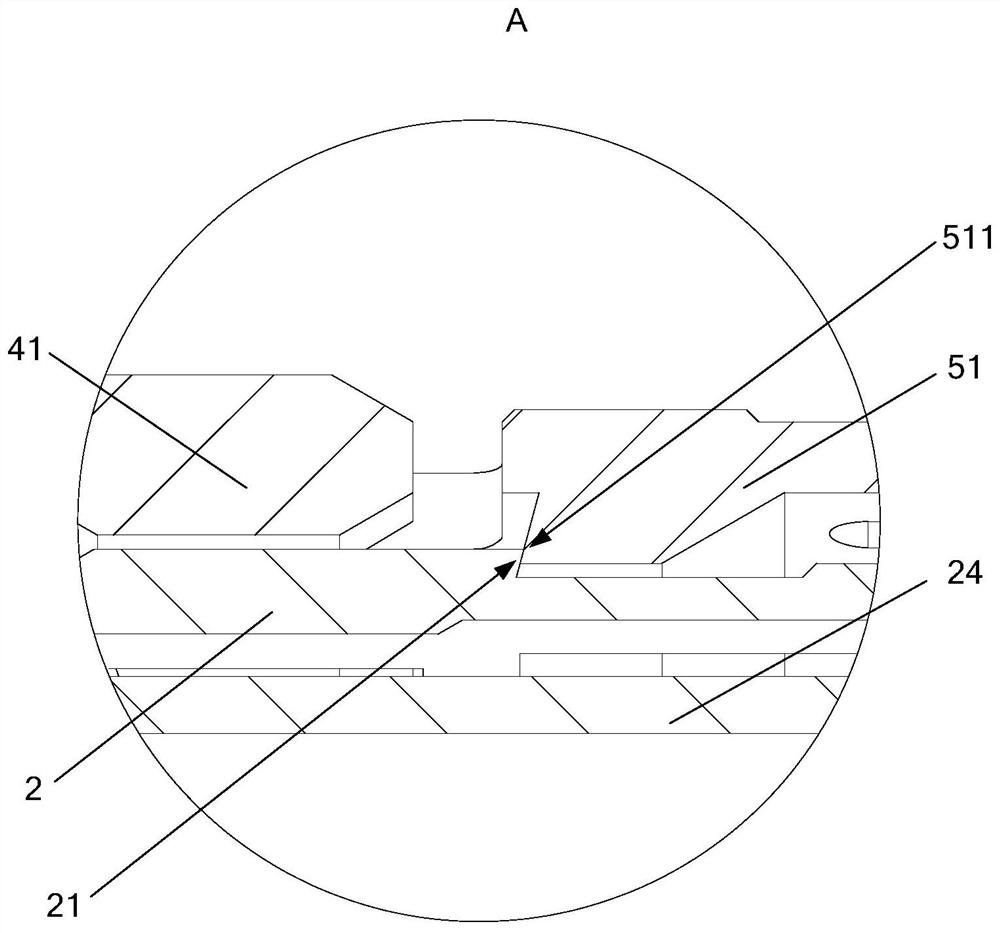

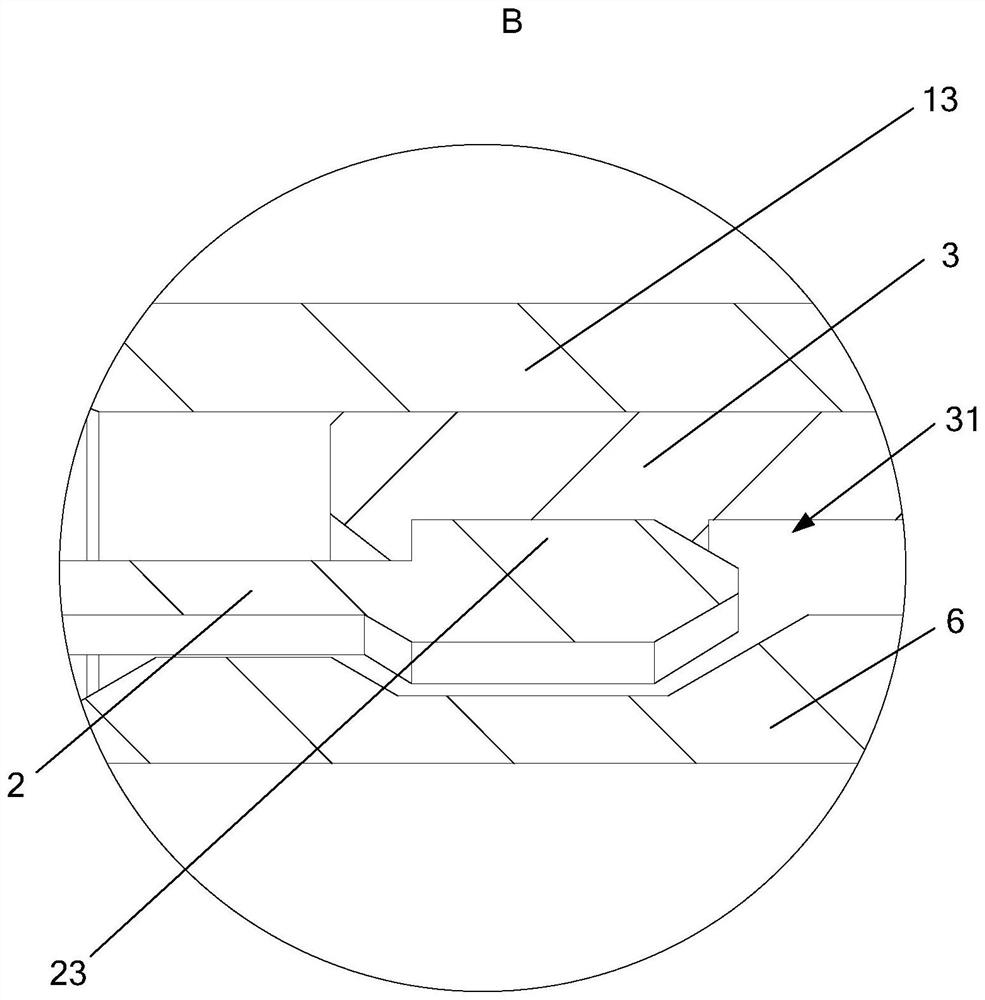

[0036] Embodiments of the present invention provide a plugging device for coiled tubing operations, such as figure 1 As shown, it includes a plug body 1, an elastic sleeve 2, a thrust ring 6, a limit device 3, a first positioning cylinder 4 and a second positioning cylinder 5, and the first positioning cylinder 4 and the second positioning cylinder 5 is fixed on the plug body 1, the first positioning cylinder 4 is provided with a first positioning claw 41, the second positioning cylinder 5 is provided with a second positioning claw 51, and the thrust ring 6 and the limiting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com