A vibration-sensing corrugated diaphragm, an optical fiber acceleration sensor and a micro-vibration detection system

A corrugated diaphragm and optical fiber technology, applied in the direction of using inertial force for acceleration measurement, instruments, measuring devices, etc., can solve the problems affecting the interference efficiency of the interferometer, the demodulation signal instability, the thickness of the diaphragm, etc., and achieve the optical path structure. Simple and reliable, improve the interference efficiency, the effect of little metal composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

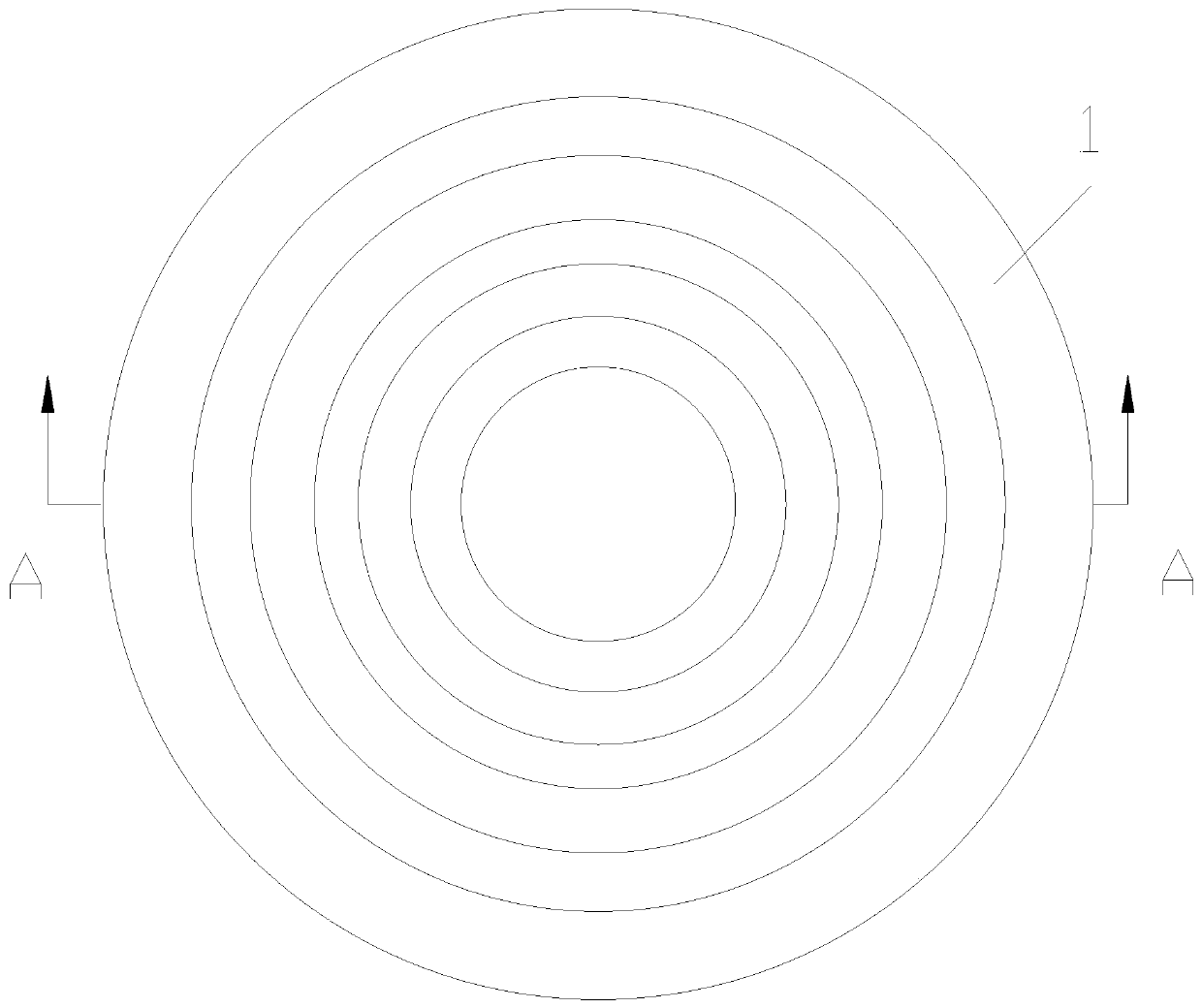

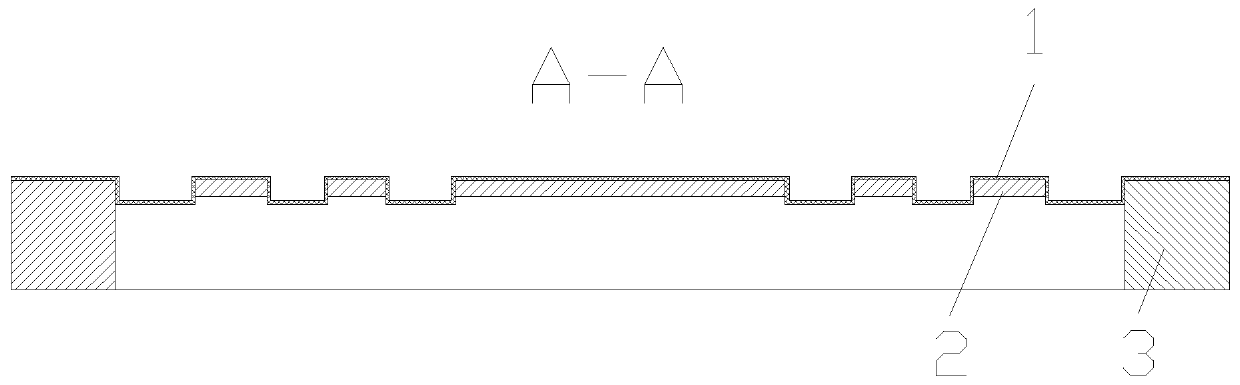

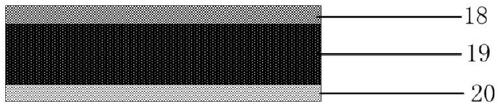

[0038] see Figure 1 to Figure 3, this embodiment discloses a vibration-sensing corrugated diaphragm, which includes a composite film 1 and a plurality of annular mass blocks 2, the overall shape of the composite film 1 is a disk-shaped structure with uniform wall thickness, and the composite film 1 is from top to bottom The reflective metal film 18, the organic film 19 and the anti-etching metal film 20 are stacked in sequence below, and the reflectivity of the reflective metal film 18 is greater than 90%. The outer edge of the composite film 1 is supported by an annular support block 3 , which is arranged concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com