A kind of pulse power source and semiconductor device

A pulsed power source, semiconductor technology, applied in vacuum evaporation plating, coating, discharge tube, etc., can solve the problems of matcher 8 mismatch, process stop, impedance can not keep up, etc., to improve stability and improve impedance Stability, ensuring the effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

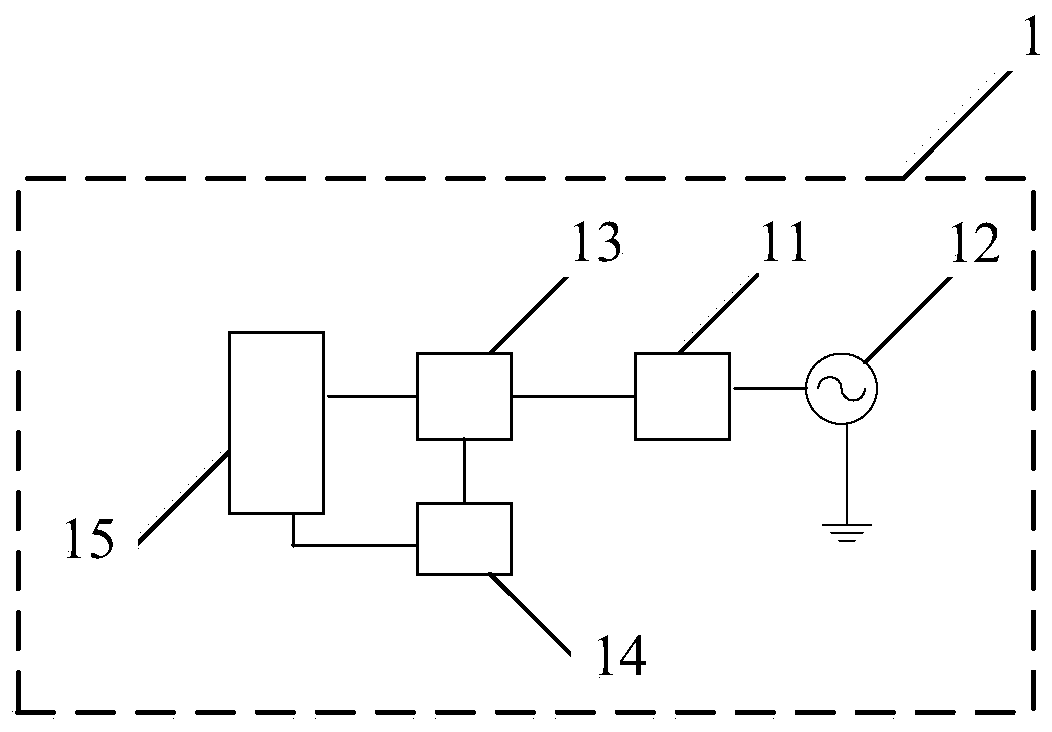

[0060] Such as Figure 2a As shown, Embodiment 1 of the present invention provides a pulsed power source 1 , including a matching unit 11 , and also includes a continuous wave power source 12 , a power divider 13 , a first phase shifter 14 and a first power combiner 15 . The power divider 13 has at least two output terminals, and the first power combiner 15 has at least two input terminals.

[0061] The input end and the output end of the matcher 11 are respectively connected with the output end of the continuous wave power source 12 and the input end of the power divider 13, and the first output end of the power divider 13 is connected with the first input end of the first power combiner 15 The second output end of the power splitter 13 is connected to the second input end of the first power combiner 15 via the first phase shifter 14 .

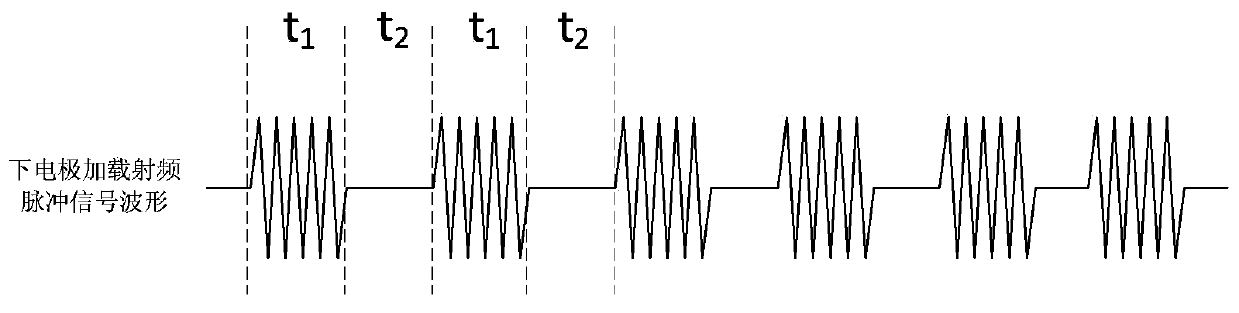

[0062] The continuous wave power signal output by the continuous wave power source 12 is distributed into at least two power signals by the...

Embodiment 2

[0077] Embodiment 2 of the present invention provides a pulsed power source. The difference between Embodiment 2 and Embodiment 1 is that a set of phase shifters and power combiners are added, thereby increasing a set of radio frequency pulse signal outputs.

[0078] Such as Figure 2b As shown, Embodiment 2 provides a pulsed power source 2, including a matcher 21, a continuous wave power source 22, a power divider 23, a second phase shifter 24, a second power combiner 25, and a third phase shifter 26 and a third power combiner 27 . The power divider 23 has at least four output terminals, and the second power combiner 25 and the third power combiner 27 have at least two input terminals.

[0079] The input end and the output end of the matcher 21 are connected with the output end of the continuous wave power source 22 and the input end of the power divider 23 respectively, and the first output end of the power divider 23 is connected with the first input end of the second powe...

Embodiment 3

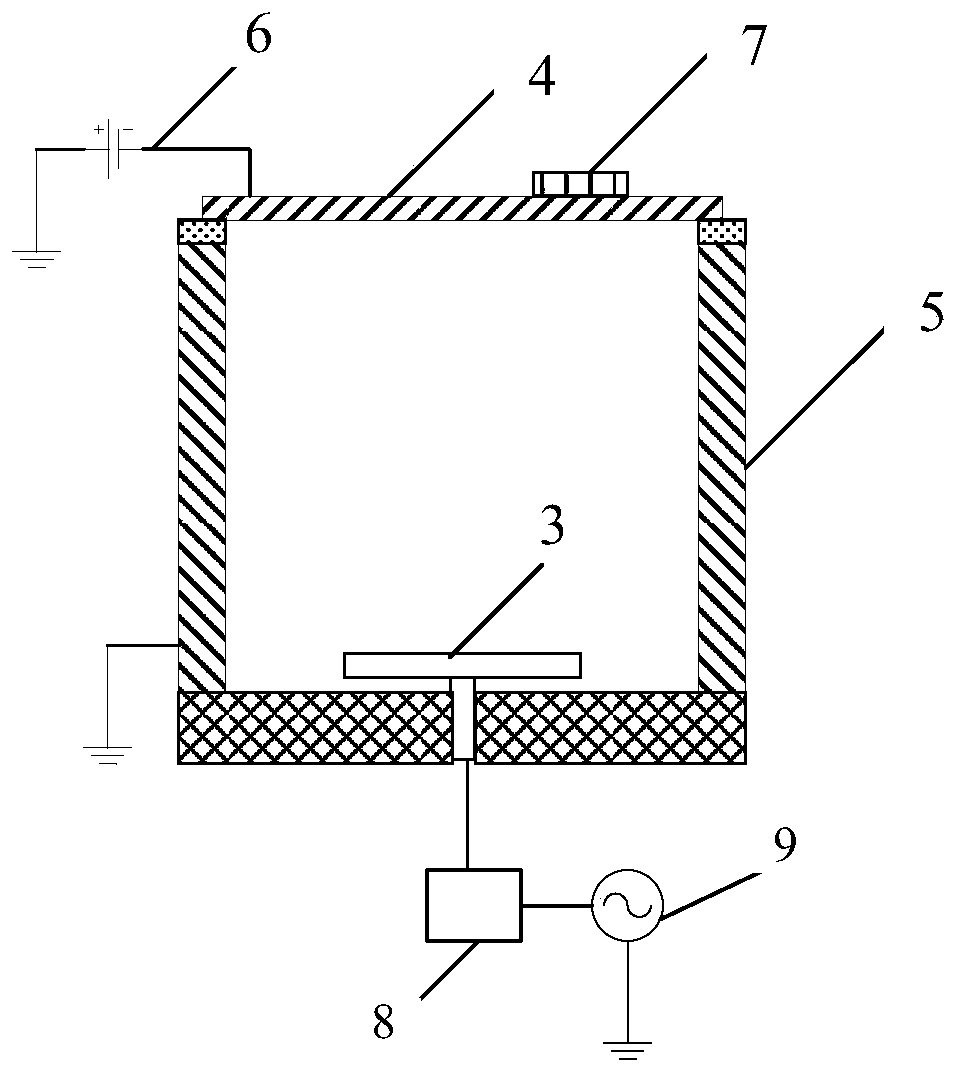

[0087] Such as image 3 As shown, embodiment 3 provides a kind of semiconductor equipment, and described semiconductor equipment is physical vapor deposition equipment, comprises pulse power source 1, reaction chamber 5, base 3 and target material 4, and target material 4 and reaction chamber 5 The side walls are sealed and connected, and the base 3 is accommodated in the reaction chamber 5 . Pulse power source 1 is the pulse power source that embodiment 1 provides, and wherein, pulse power source 1 is one, the output end of pulse power source 1 (that is the output end of first power combiner 15) and described physical vapor deposition equipment The base 3 is connected.

[0088] The semiconductor device also includes a DC power supply 6 and a magnetron 7. The DC power supply 6, the target 4 and the magnetron 7 form an upper electrode. The DC power supply 6 applies DC power to the target 4 to generate plasma.

[0089] In embodiment 3, the pulse power source 1 in embodiment 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com