Cultivation column and vertical water cultivation planting equipment

A column and planting basket technology, applied in the field of vertical hydroponic planting equipment, can solve the problems of different suitable places, inability to place, and different methods, and achieve the effects of saving nutrient solution, occupying a small space, and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

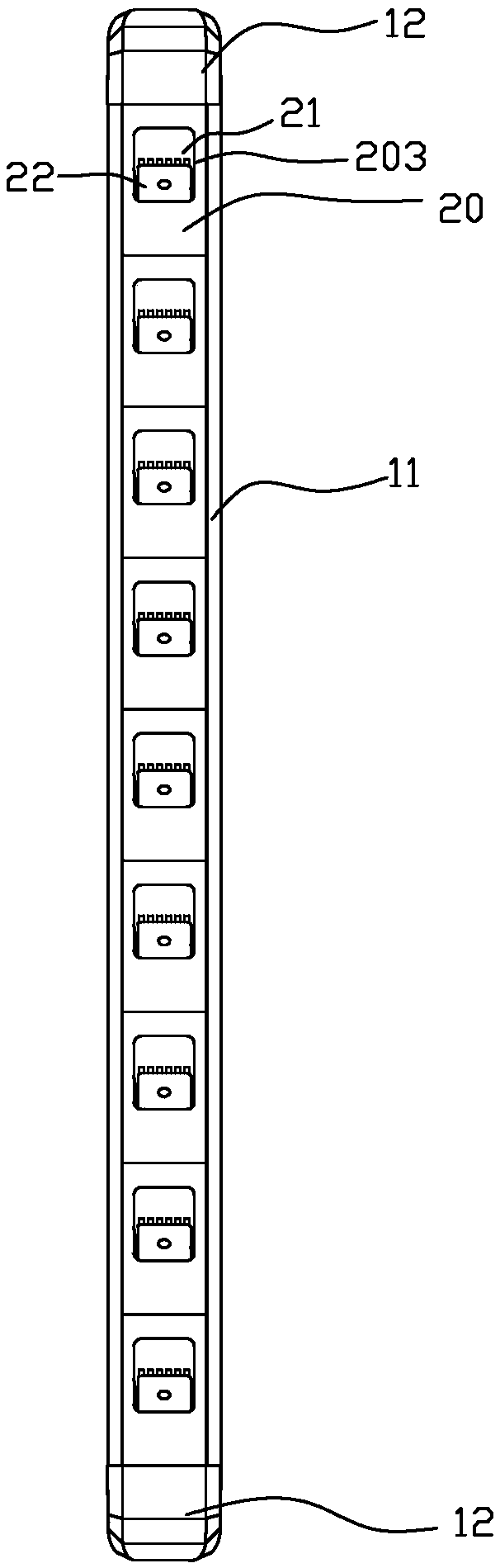

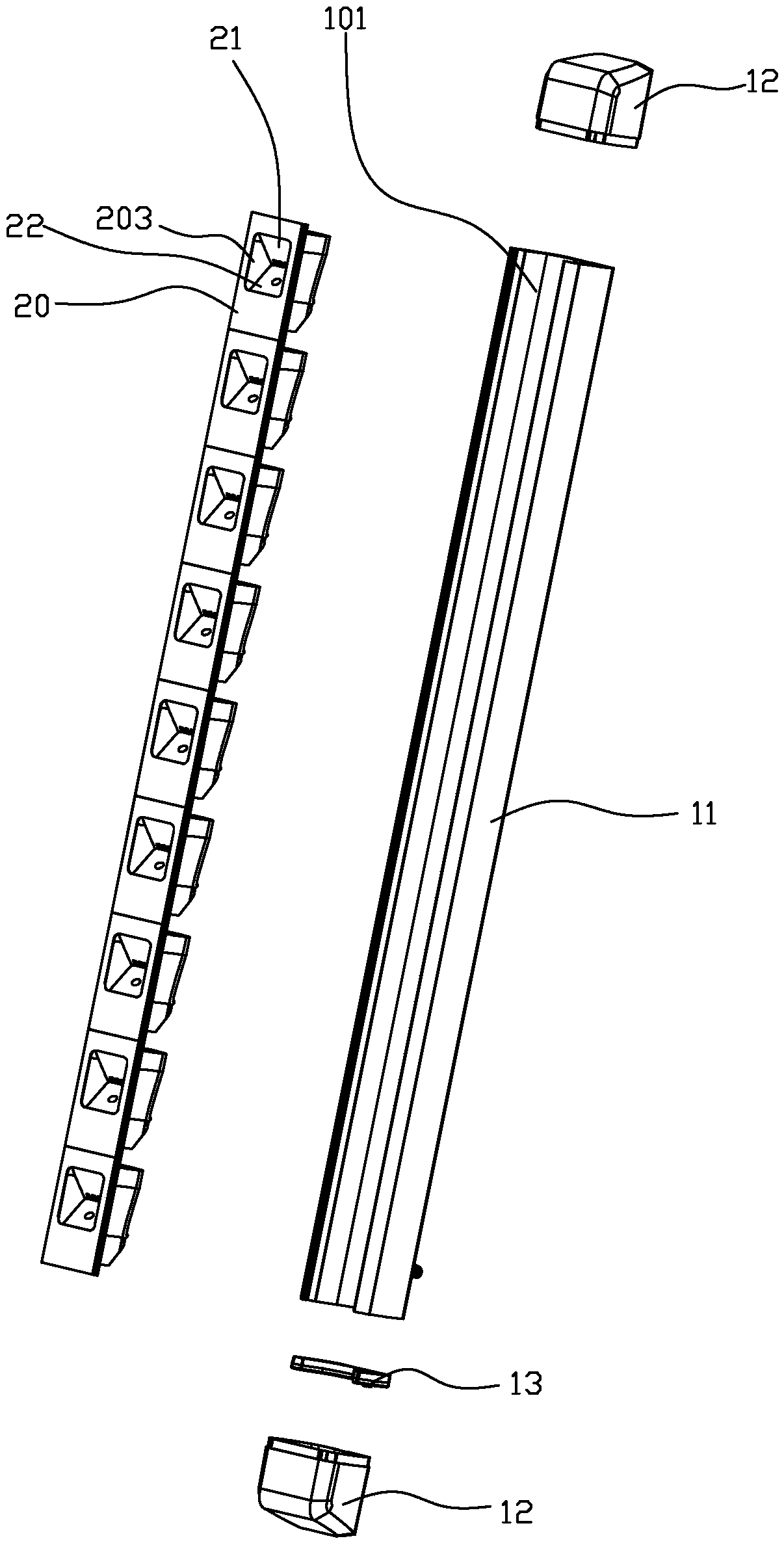

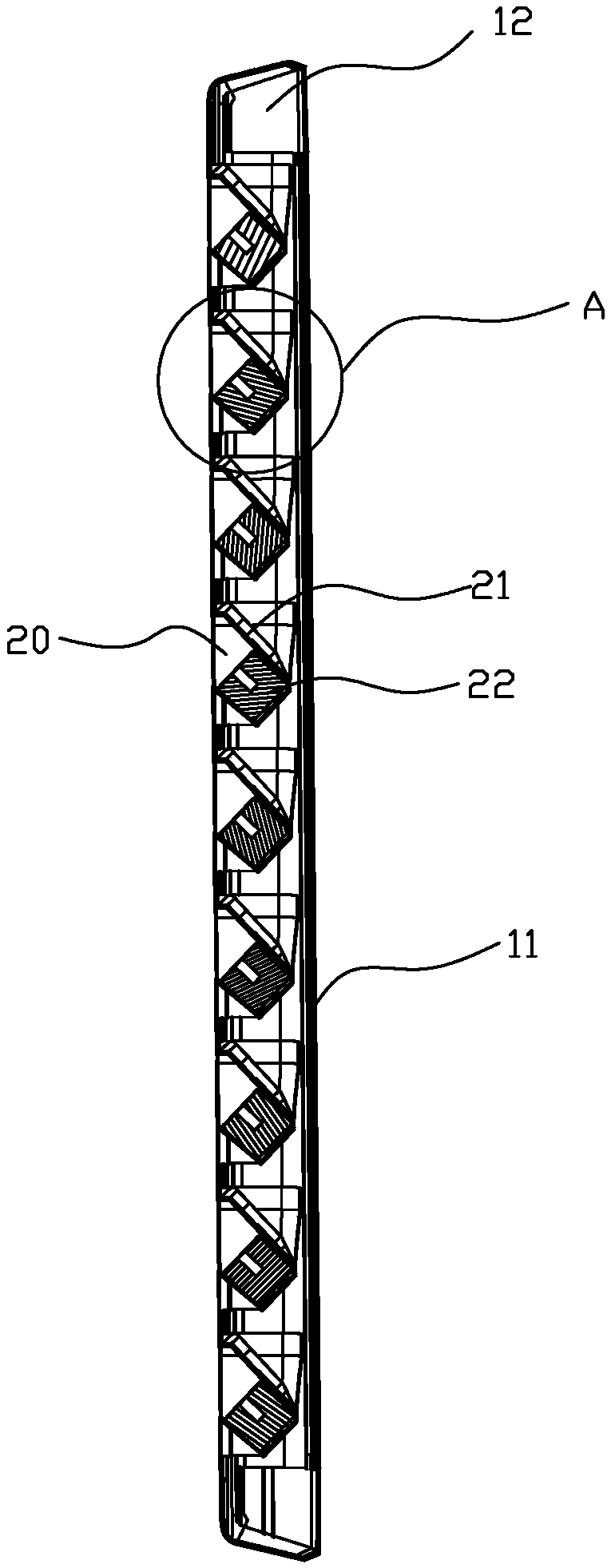

[0036] refer to Figure 1 to Figure 9 As shown, a cultivation column provided in this embodiment includes a columnar support and a plurality of planting baskets 20. The columnar support includes a profile 11 and end caps 12 arranged at both ends of the profile 11. The profile 11 is vertical Set to form a column structure; the profile 11 has a planting groove 101 arranged along its length direction (i.e. vertically), the notch of the planting groove 101 is opened on the side wall of the column support, and at the same time, the profile 11 is also provided with a nutrient solution storage cavity 102 arranged along its length direction. The nutrient solution storage cavity 102 is isolated from the planting tank 101. The end caps 12 cover both ends of the profile 11 . In this embodiment, the planting tank 101 and the nutrient solution storage chamber 102 are integrally formed by the profile 11, which is easy to manufacture. In other embodiments, the profile 11 may also be replac...

Embodiment 2

[0046] refer to Figure 10 As shown, in this specific embodiment, the structure is roughly the same as that of Embodiment 1, the difference is that in this embodiment, the columnar bracket is provided with two planting grooves 101, and the two planting grooves 101 are arranged opposite to each other. The nutrient solution storage chamber 102 is arranged between the two planting grooves 101, further increasing the planting area. In other embodiments, the number of planting grooves can also be increased or decreased according to actual conditions, and no examples will be given here.

Embodiment 3

[0048] In this specific embodiment, the structure is roughly the same as that of Embodiment 1. The difference is that in this embodiment, the bottom plate of the planting basket is a tapered groove with a "V"-shaped cross-section, and the tapered groove structure is adopted. , can also achieve the same technical effect as the "V"-shaped groove structure composed of two support plates in the first embodiment. In other embodiments, the structure of the bottom plate can also adopt other "V"-shaped structures in cross-section, such as an inverted pyramid-shaped structure; or in the tapered groove, the center of the tapered groove is chamfered to form a circular shape. The structure of the bottom surface of the arc and so on.

[0049] In the cultivation column provided by the above embodiment, at least one planting groove arranged along the length direction is provided on the columnar support, the notch of the planting groove is opened on the side wall of the columnar support, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com