Ground cleaning device for factory

A ground cleaning and factory technology, applied in cleaning equipment, cleaning machinery, applications, etc., can solve the problems of long time consumption and low work efficiency, and achieve the effect of increasing the cleaning range and reducing the work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

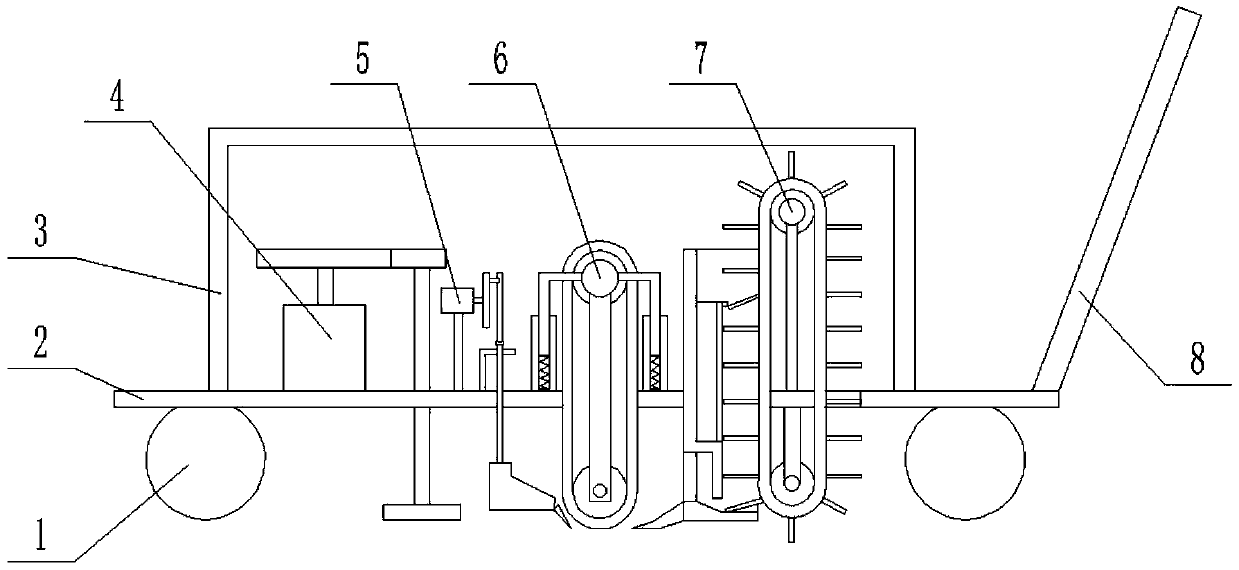

[0032] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, the present invention relates to a cleaning device, more specifically a factory floor cleaning device, including a wheel 1, a bottom plate 2 , shell 3, garbage collection device 4, blocking device 5, garbage propulsion device 6, garbage collection device 7, push handle 8, not only can gather the garbage near the bottom plate to the lower end of the bottom plate through the garbage collection device, and increase the cleaning range of the device on the ground , and can automatically collect the gathered garbage into the garbage chute, reducing the work intensity of the staff.

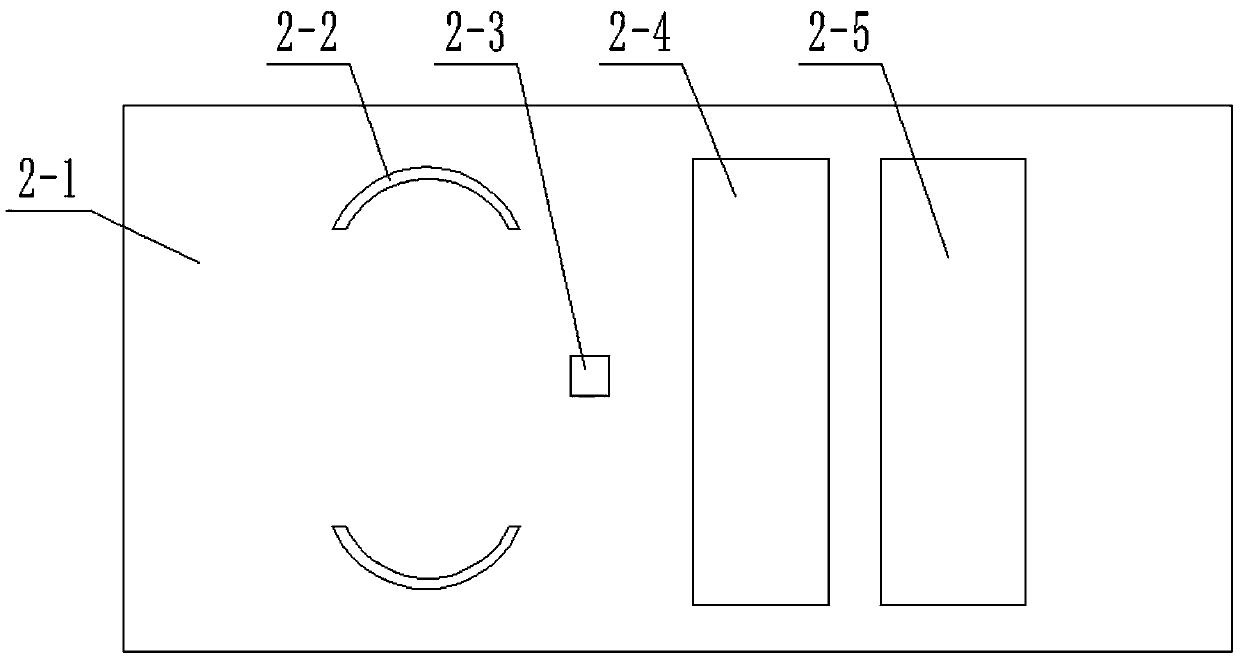

[0033] The base plate 2 is composed of a base plate main body 2-1, an arc groove 2-2, a through hole I2-3, a through hole II2-4, and a through hole III2-5; the left side of the base plate main body 2-1 is provided with an arc slot 2-2, and there are two arc-shaped slots 2-2, and the two arc-shaped slots 2-2 are ...

specific Embodiment approach 2

[0039] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11 describe this embodiment, and this embodiment will further describe Embodiment 1. The motor I4-5 is provided with a forward and reverse control circuit inside.

specific Embodiment approach 3

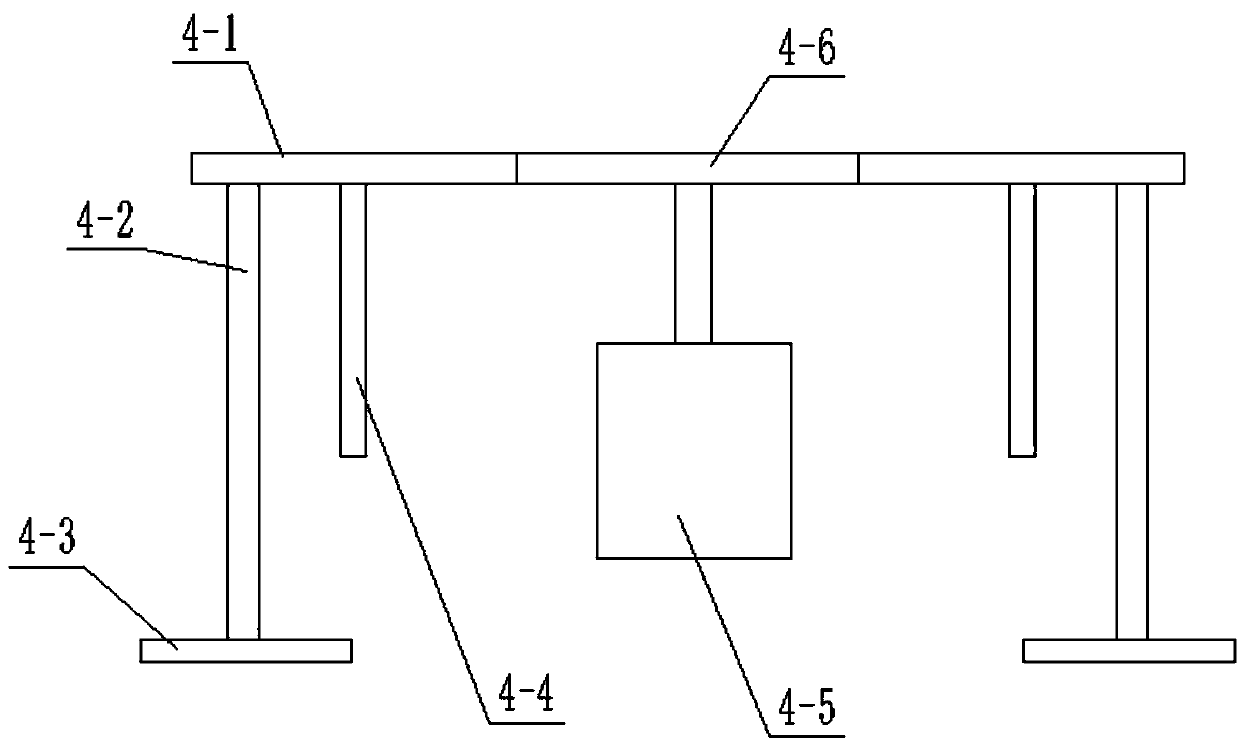

[0040] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, and 11 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The part with teeth on the side of the runner 4-1 accounts for the portion of the runner 4 -1 third of the side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com