Efficient printing ink filtering device

A technology of filtering device and ink, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of poor fluidity, reduced filtration rate, inconvenient to use, etc., to improve filtration efficiency, convenient use and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further clarified below in conjunction with specific drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

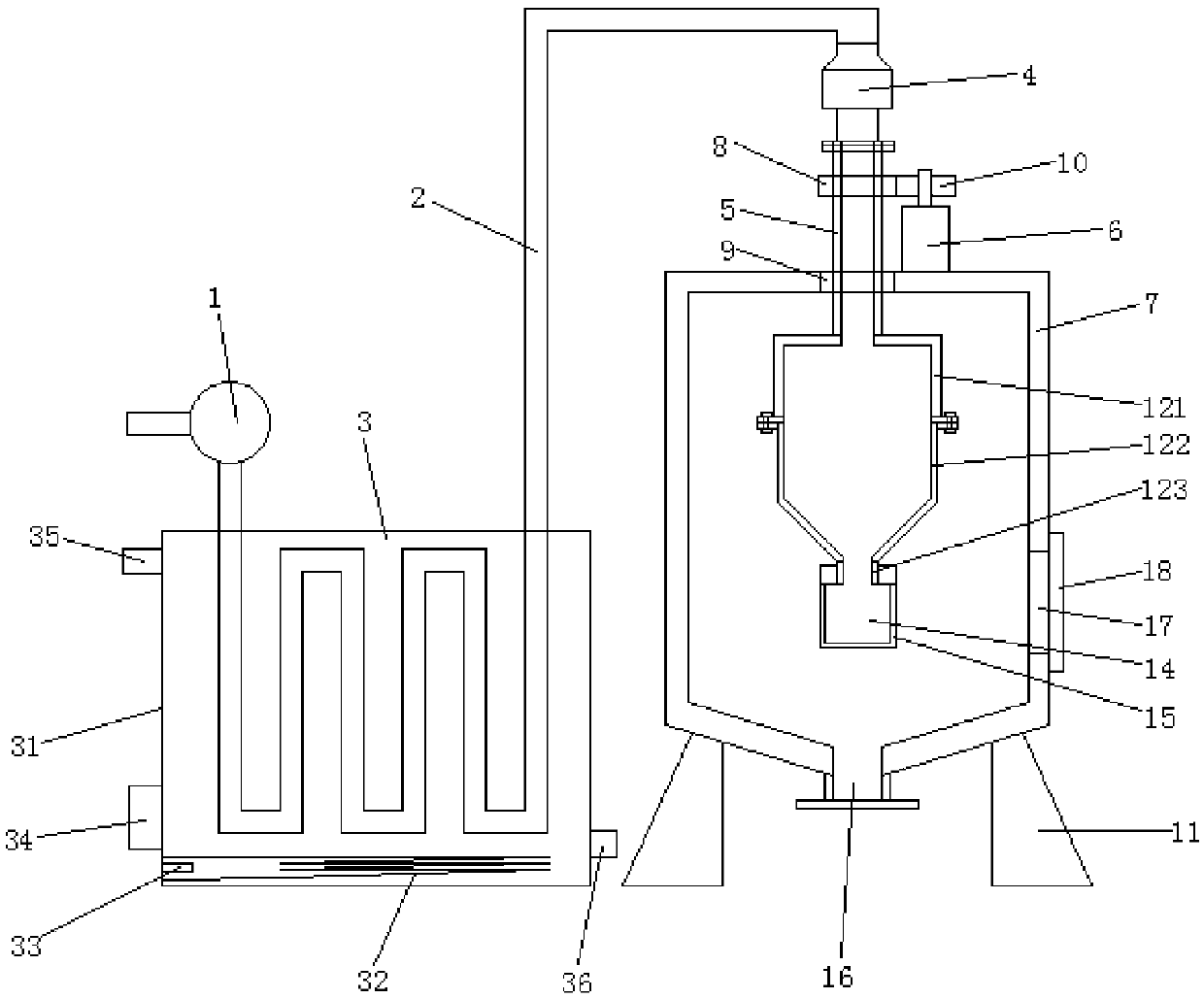

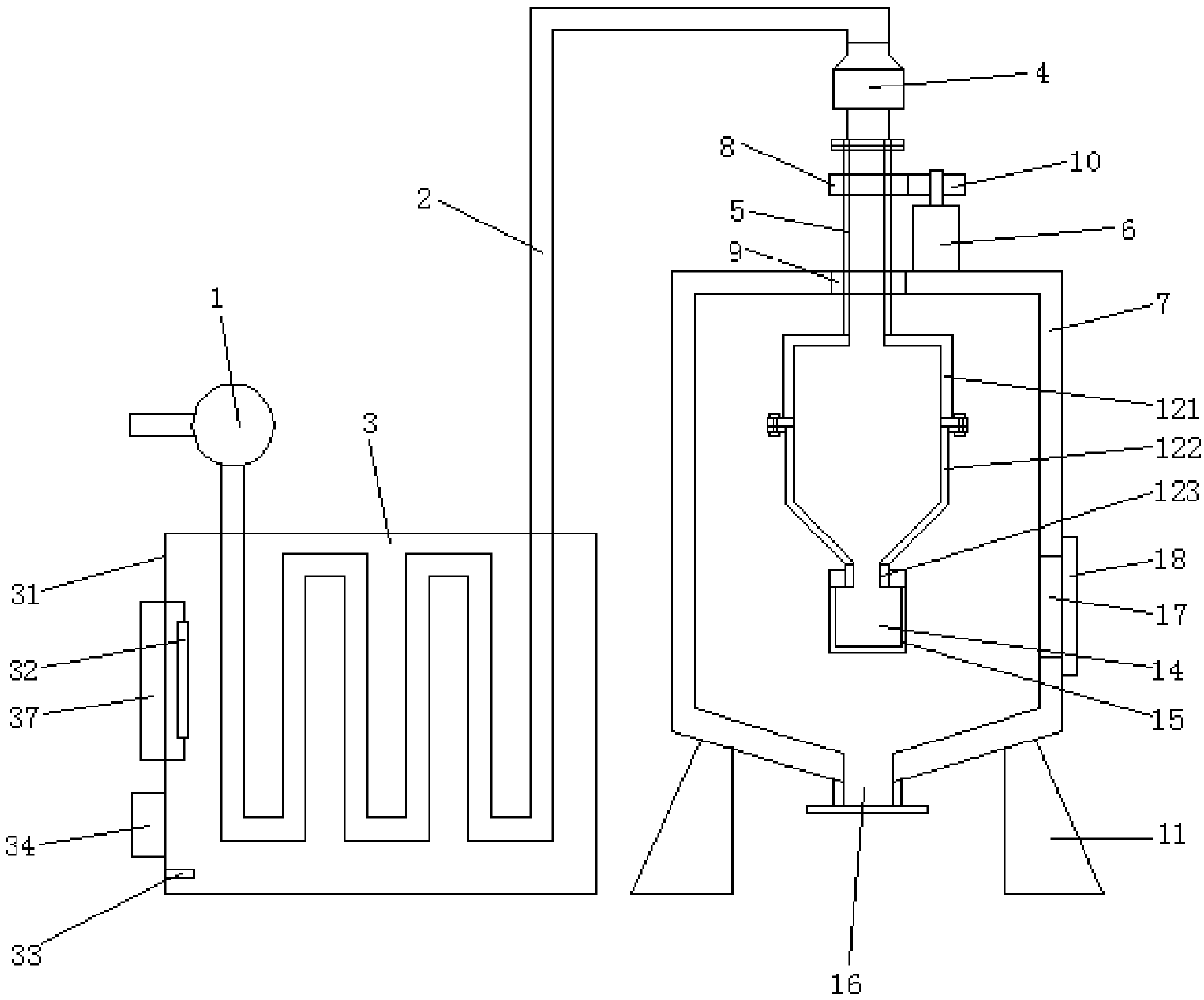

[0016] Such as figure 1 or 2, the embodiment of the present invention provides a high-efficiency ink filtration device, which includes a delivery pump 1, a delivery pipe 2, a heating box 3, a rotary joint 4, a feed pipe 5, a motor 6 and a filter tank 7, and the delivery The inlet of the pump 1 is set in the ink of the printer to pump the ink to be filtered. The outlet of the delivery pump 1 is connected to the delivery pipe 2, and the delivery pipe 2 penetrates from one side of the heating box 3 and passes out from the side of the heating box 3. In order to improve the heating effect, the delivery pipe 2 in the heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com