Vibration type filtering equipment for oil exploitation

A filtration equipment, oil extraction technology, applied in the direction of filtration and separation, production of fluid, filtration circuit, etc., can solve the problems of blocked work, difficult to filter, easy to stick to the net, etc., and achieve the effect of increasing the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

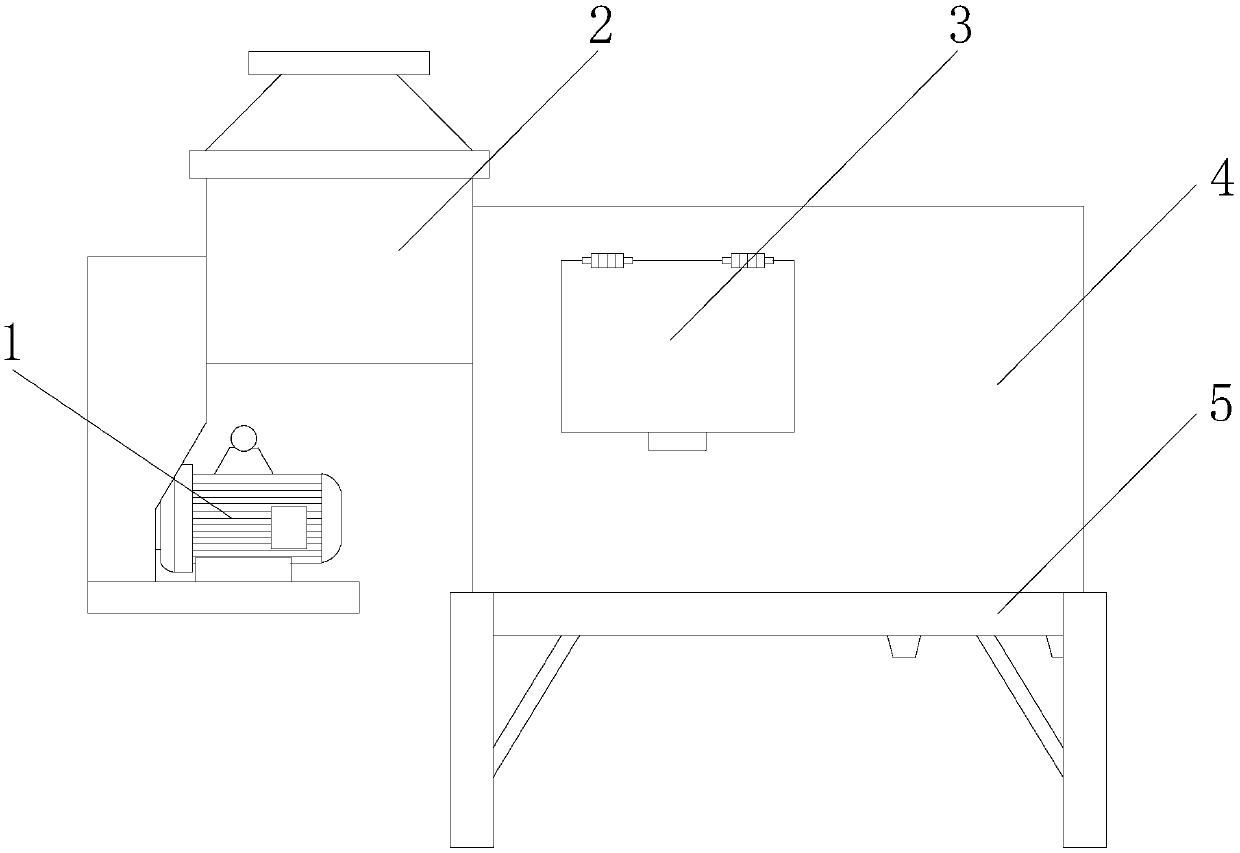

[0023] see Figure 1-Figure 4 , the present invention provides vibrating filter equipment for oil exploitation, its structure includes a motor 1, an oil inlet 2, a box door 3, a filter host 4, and a support frame 5, the motor 1 is mechanically connected to the oil inlet 2, and the The oil inlet 2 is fixedly installed on the left upper end of the filter host 4, the box door 3 is hinged with the front surface of the filter host 4, and the lower end of the filter host 4 is fixedly installed on the support frame 5 upper end.

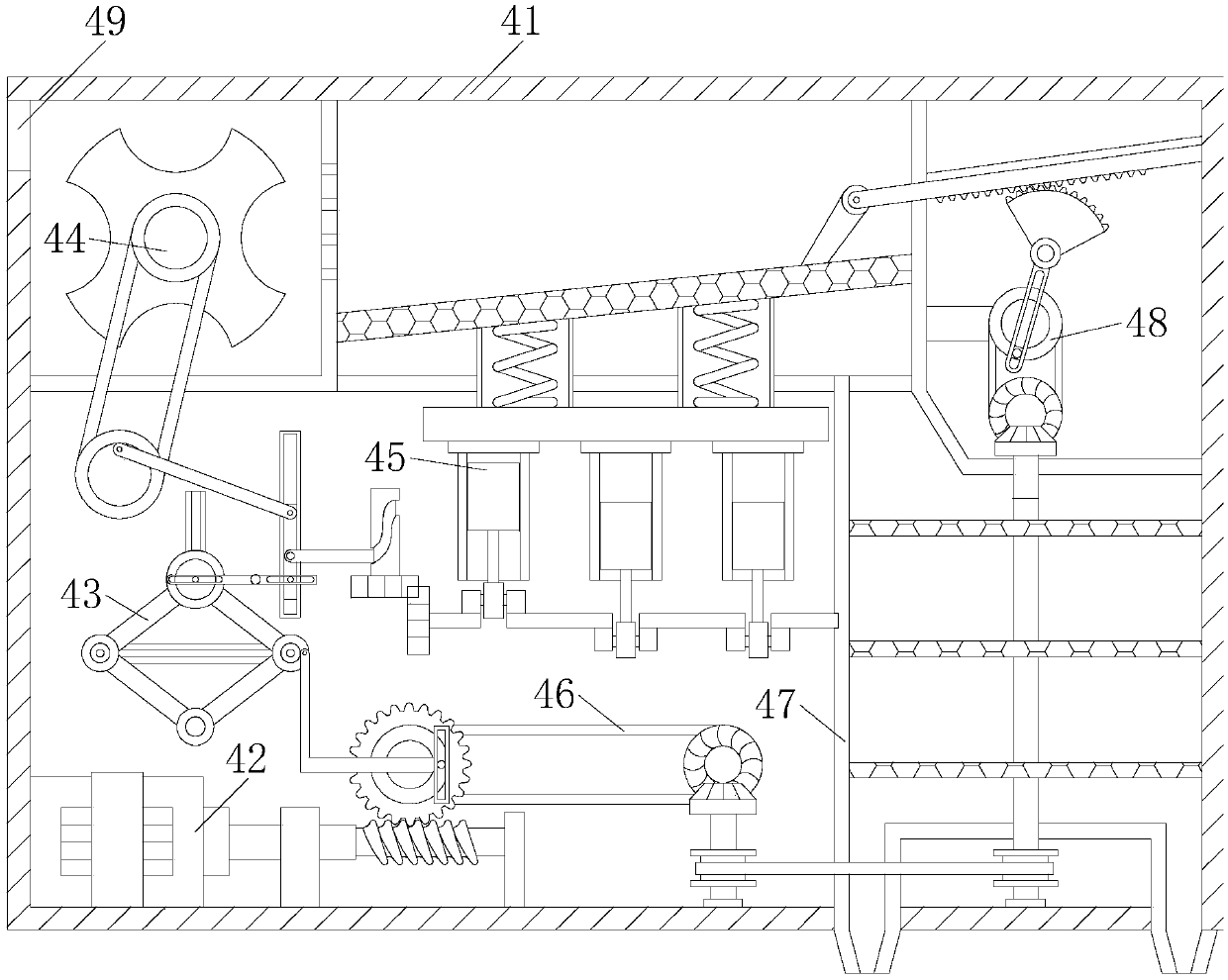

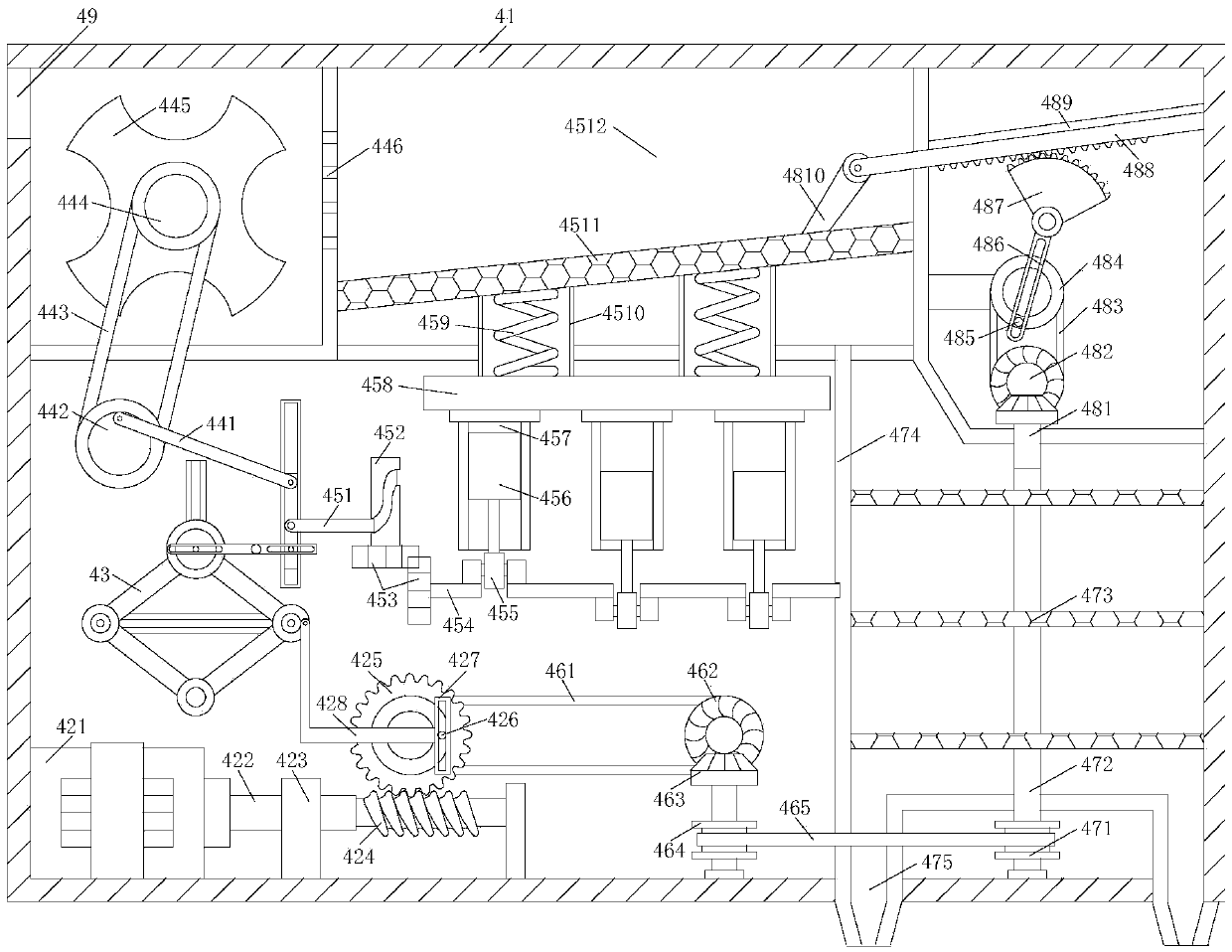

[0024] The filter host 4 includes a casing 41, a power mechanism 42, a main transmission mechanism 43, a primary screening mechanism 44, an air pressure vibration filter mechanism 45, a drive mechanism 46, a secondary filter mechanism 47, a scraping mechanism 48, and a connection port 49. The upper left end of the casing 41 is provided with a connecting port 49, the connecting port 49 is connected to the oil inlet 2, a power mechanism 42 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com