Movable 3D printing system

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve problems such as molding failure, inability to print, insufficient precision and surface quality, etc., to achieve the effect of expanding application scenarios, shortening delivery cycle, and improving 3D printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

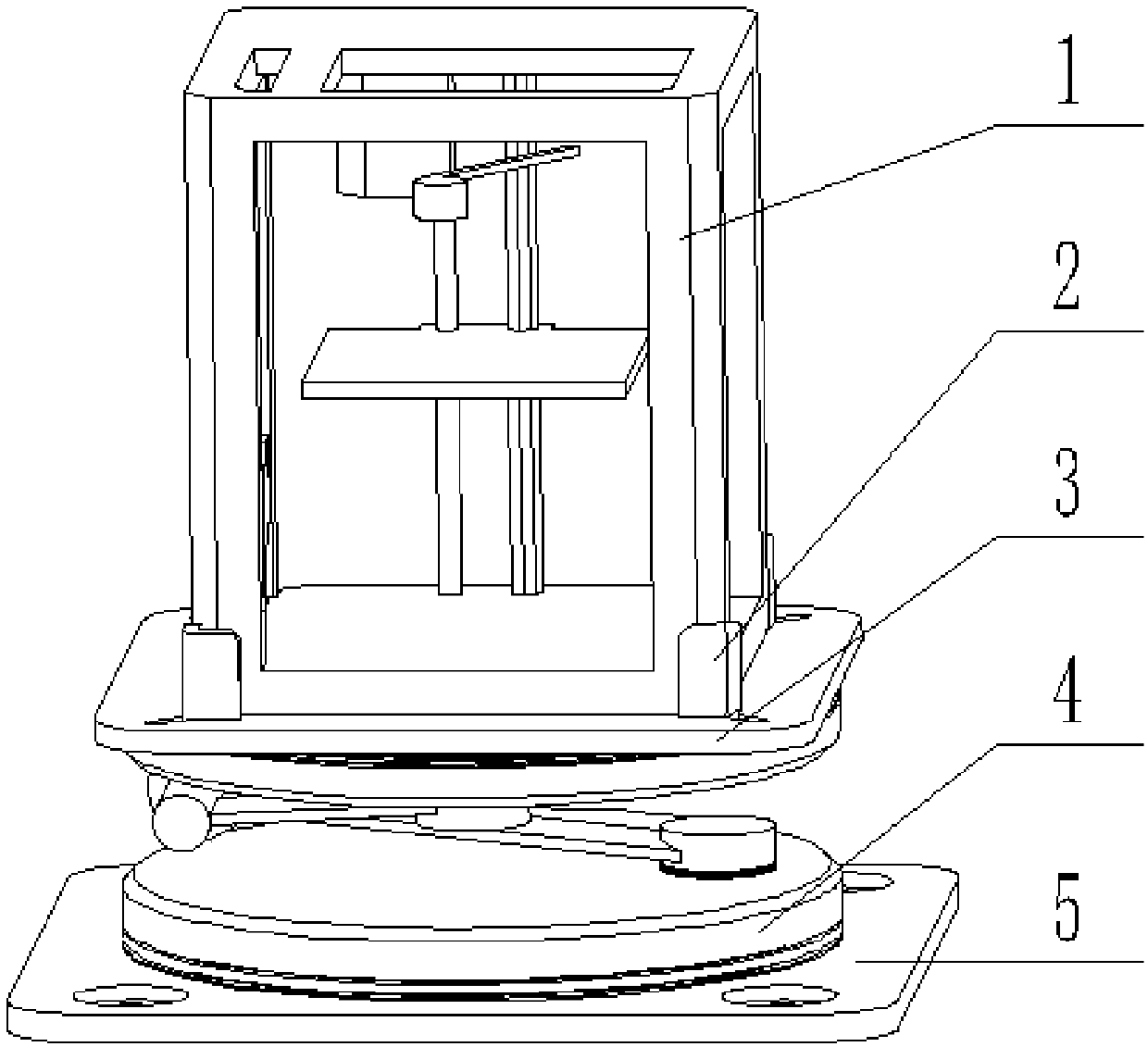

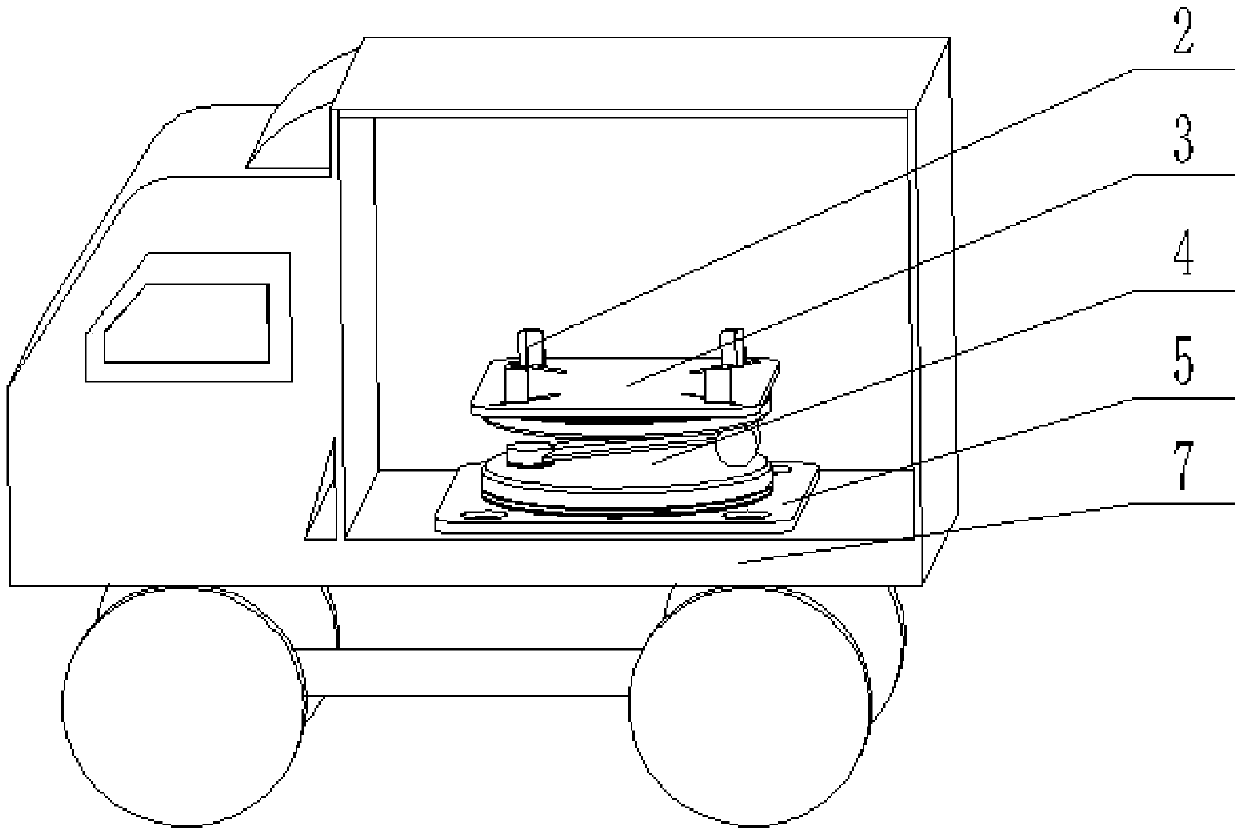

[0016] The present invention proposes a mobile 3D printing system, such as figure 1 As shown, it consists of a 3D printer 1, a mechanical pan / tilt 4, a spring holder 2, a 3D printer installation platform 3, a pan / tilt installation base 5 and a transport vehicle 7.

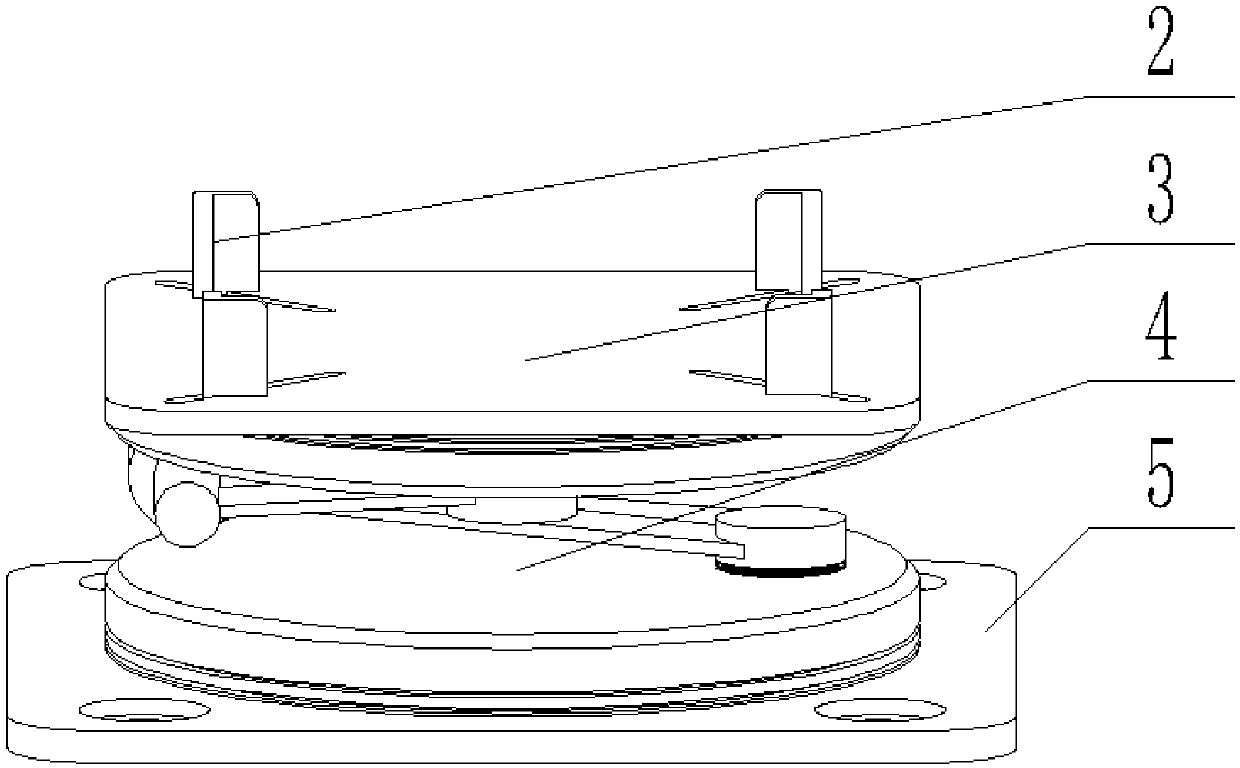

[0017] The working mode of a mobile 3D printing system of the present invention is: the 3D printer installation platform is installed on the top of the mechanical platform 4 . The 3D printer 1 is placed in the middle of the 3D printer installation platform 3, and the four corners of the platform are provided with spring holders 2. The body is installed on the central position of the 3D printer installation platform 3. The spring fixer 2 can move a certain distance in the diagonal direction of the 3D printer installation platform 3, so that the mechanical platform 4 (such as figure 2 shown) are suitable for different sizes of 3D printers1. The mechanical pan-tilt 4 is connected to the load-bearing back frame 6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com