Steel pipe transport truck

A technology of steel pipes and trucks, which is applied in transportation and packaging, vehicles used to carry long goods, vehicles used for freight, etc. It can solve problems such as easy shaking, potential safety hazards, unfavorable steel pipe protection, etc., and achieve stable placement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

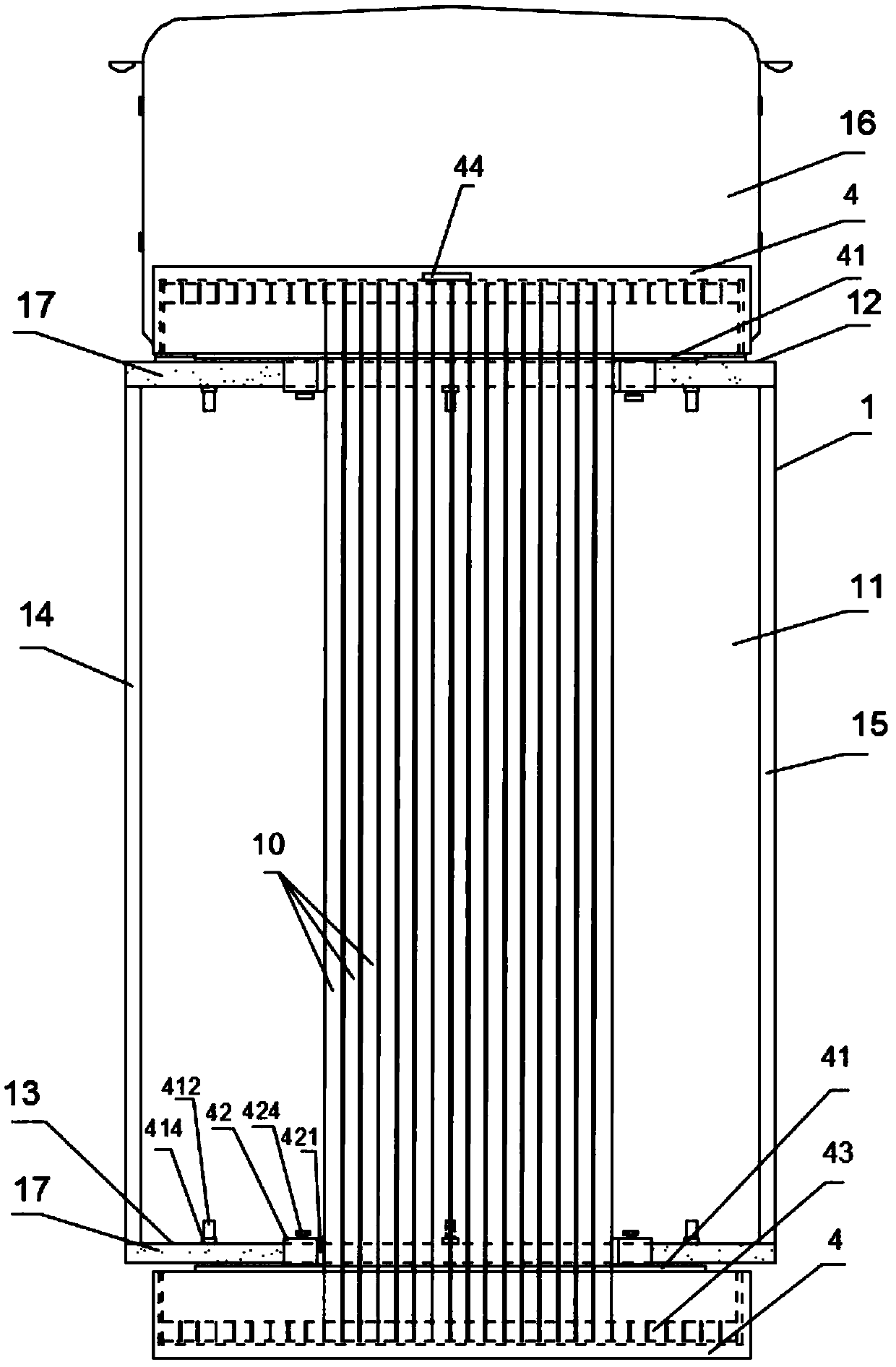

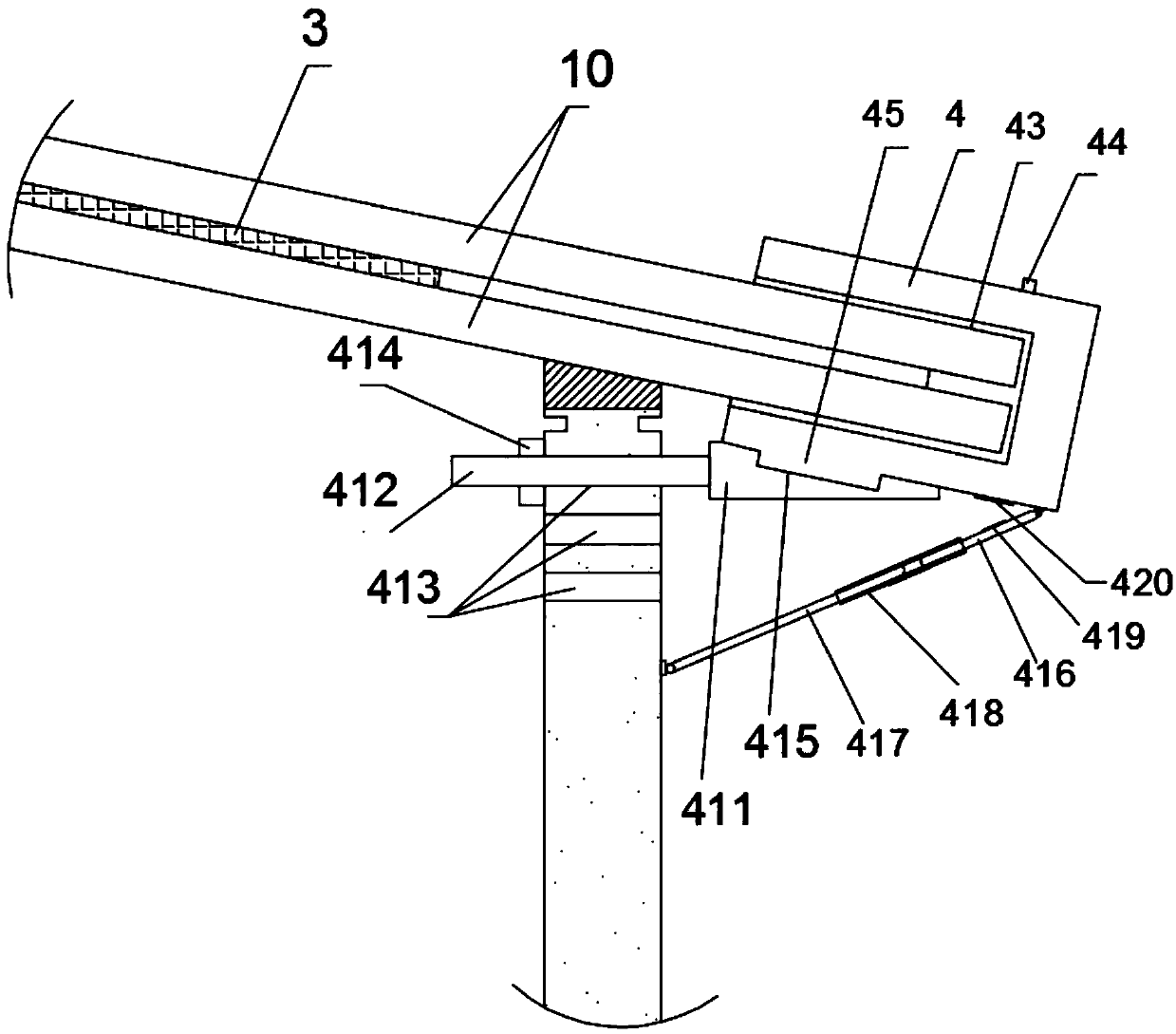

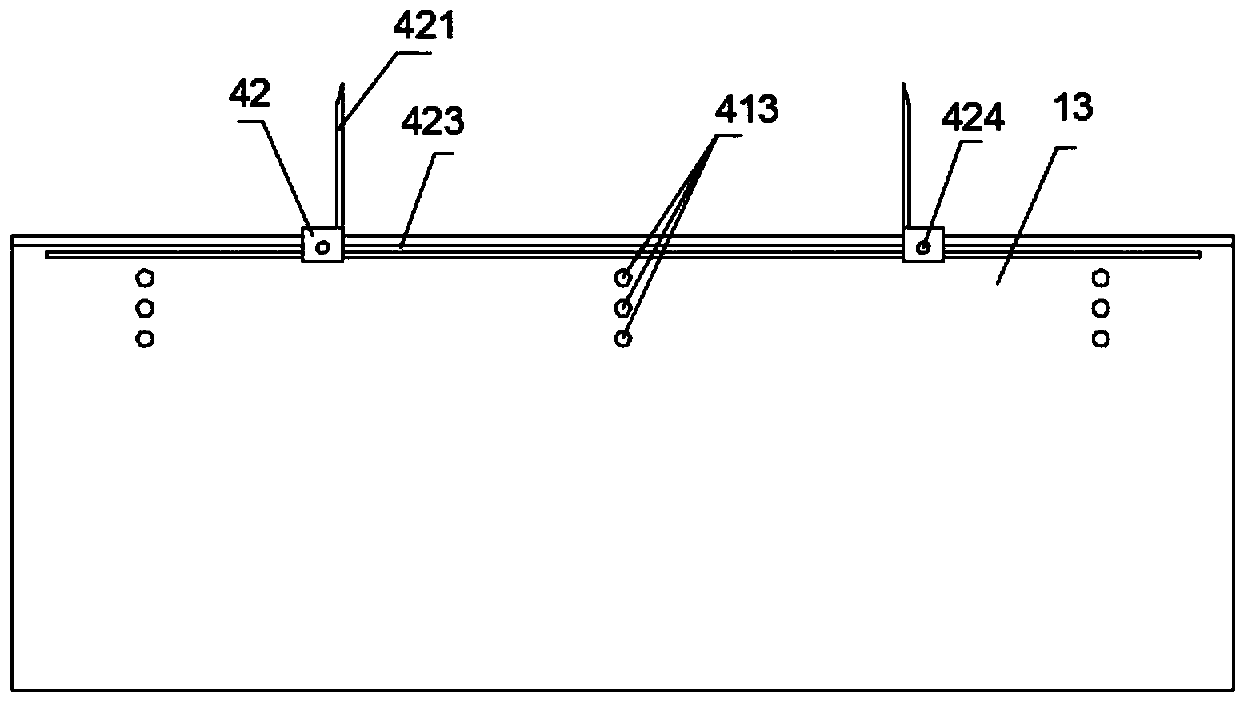

[0046] Embodiment 1, that is, the first steel pipe placement scheme provided by the present invention is:

[0047] refer to Figure 1 to Figure 4 , the top surface of the front frame 12 and the top surface of the rear side plate 13 are all fixed with a layer of rubber anti-skid pad 17, and the front frame 12 and the rear side plate 13 can be connected to the limited seat 42 in a laterally movable manner. A limited spacing is formed between the limiting seats 42, and one end of each limiting seat 42 corresponding to the limiting spacing is fixed with a vertically distributed limiting plate 421, specifically: the limiting seats 42 are provided with cavities 425 Inverted U-shaped structure with sliding parts 422 extending inwards at both ends respectively, sliding grooves 423 corresponding to sliding parts 422 are provided on the sides of the front frame 12 and rear side panel 13 respectively, and the position limiting The seat 42 is connected to the front frame 12 and the rear ...

Embodiment 2

[0053] Embodiment 2, the second steel pipe placement scheme provided by the present invention is:

[0054] refer to Figure 7 to Figure 9 As shown, a placement box 5 is fixed on the front side of the front frame 12, and several placement grooves 51 corresponding to the steel pipes 10 are embedded in the placement box 5, and the rear end of the placement grooves 51 extends to the front frame 12. On the rear side, a horizontally distributed supporting seat 52 is fixed on the rear side of the front frame 12, and the two ends of the supporting seat 52 are respectively slidably connected with a first sliding seat 521 that can move horizontally left and right, and the first sliding seats on both sides There is a placement gap between 521 , and a first clamping plate 522 distributed vertically upwards is fixed on one end of the first sliding seat 521 corresponding to the placement gap. The top surface of the rear side plate 13 is slidably connected with a second sliding seat 523 tha...

Embodiment 3

[0059] Embodiment three, the third steel pipe placement scheme provided by the present invention is:

[0060] refer to Figure 10 to Figure 14 A placement box 5 is fixed on the front side of the front frame 12, and several placement grooves 51 corresponding to the steel pipes 10 are embedded in the placement box 5, and the rear end of the placement grooves 51 extends to the rear side of the front frame 12. . Rubber anti-skid pads 17 are all fixed on the top surface of the rear side plate 13 in the described placement groove 51, and the front end of the steel pipe 10 is snapped into the placement groove 51 of the placement box 5, and the rear end is placed on the rear side plate 13. Anti-skid pad 17, avoids steel pipe directly contacting front frame, rear side panel, prevents from shaking and friction damage steel pipe during transportation. Simultaneously, on the rear side of the front frame 12, a laterally distributed support frame 6 is fixed, and the support frame 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com