Scrapping knife device used for cleaning heating cylinder during paper making

A scraper device and scraper technology, applied in the direction of scrapers, papermaking, paper machines, etc., can solve the problems of uneven force on the scraper, unclean scraping, falling of garbage and glue impurities, etc., to avoid uneven force, scraping Remove better effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

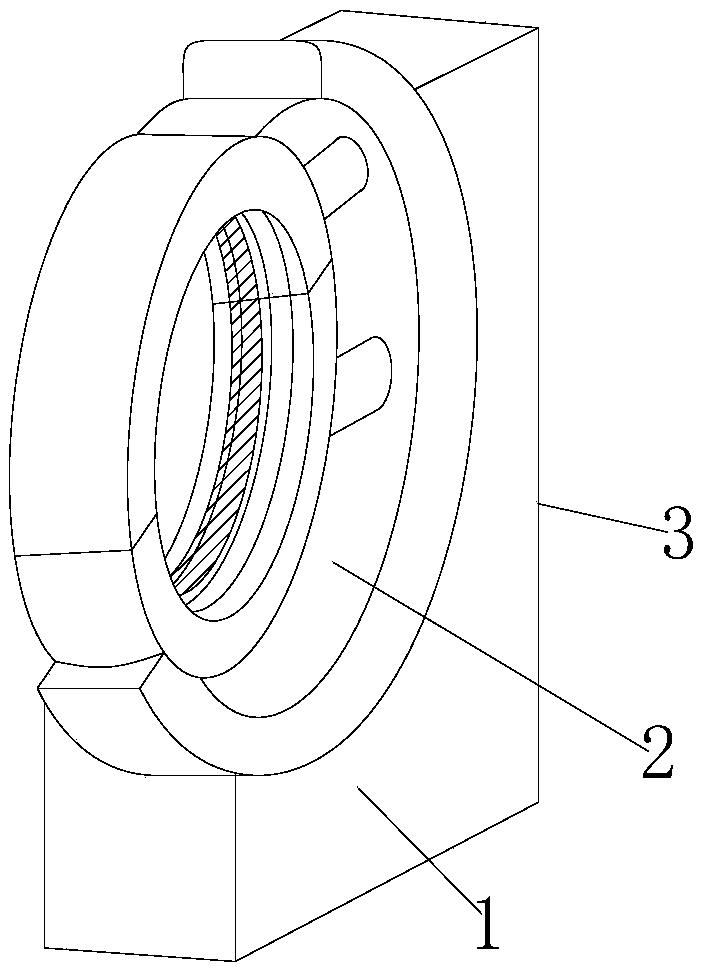

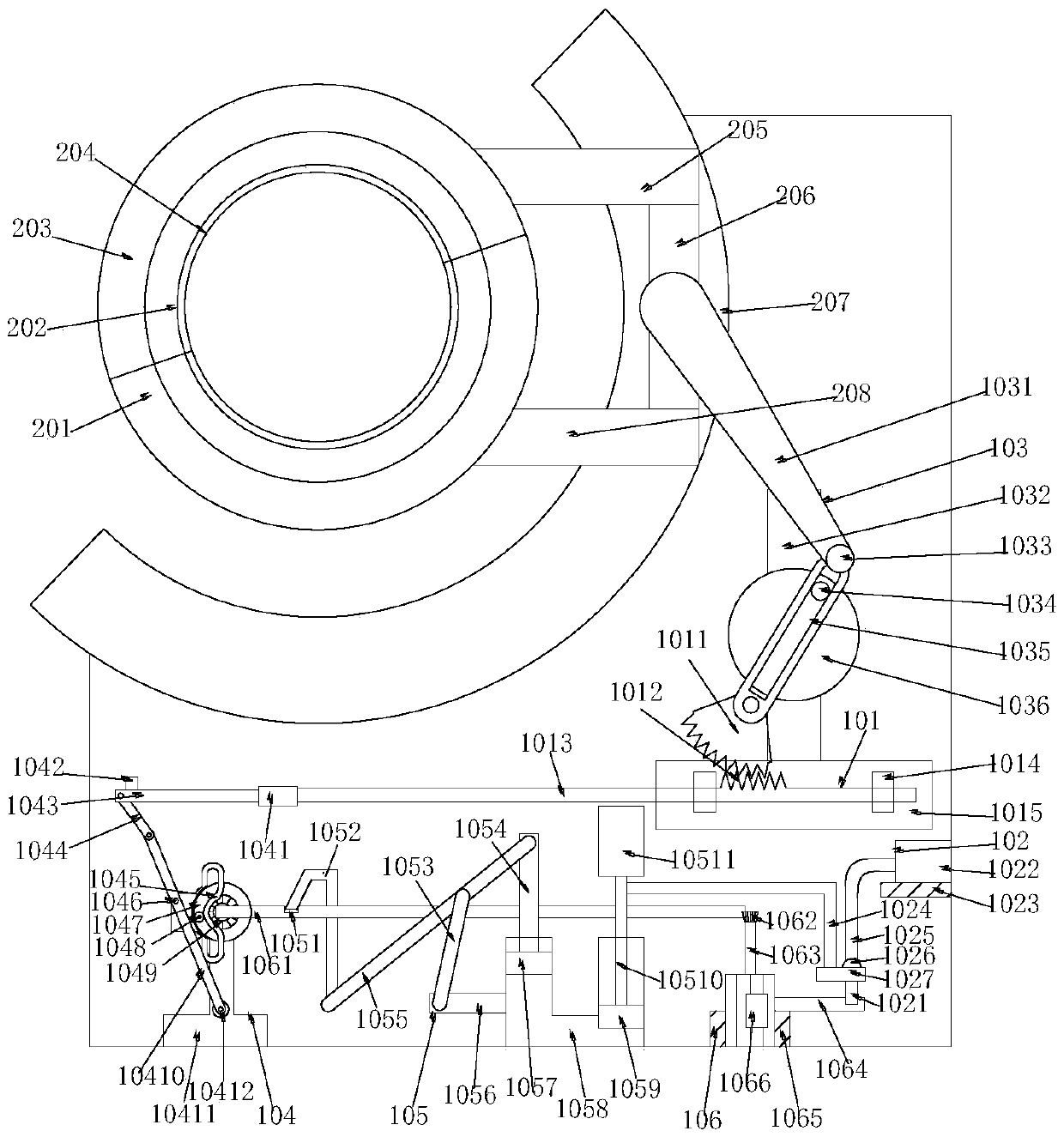

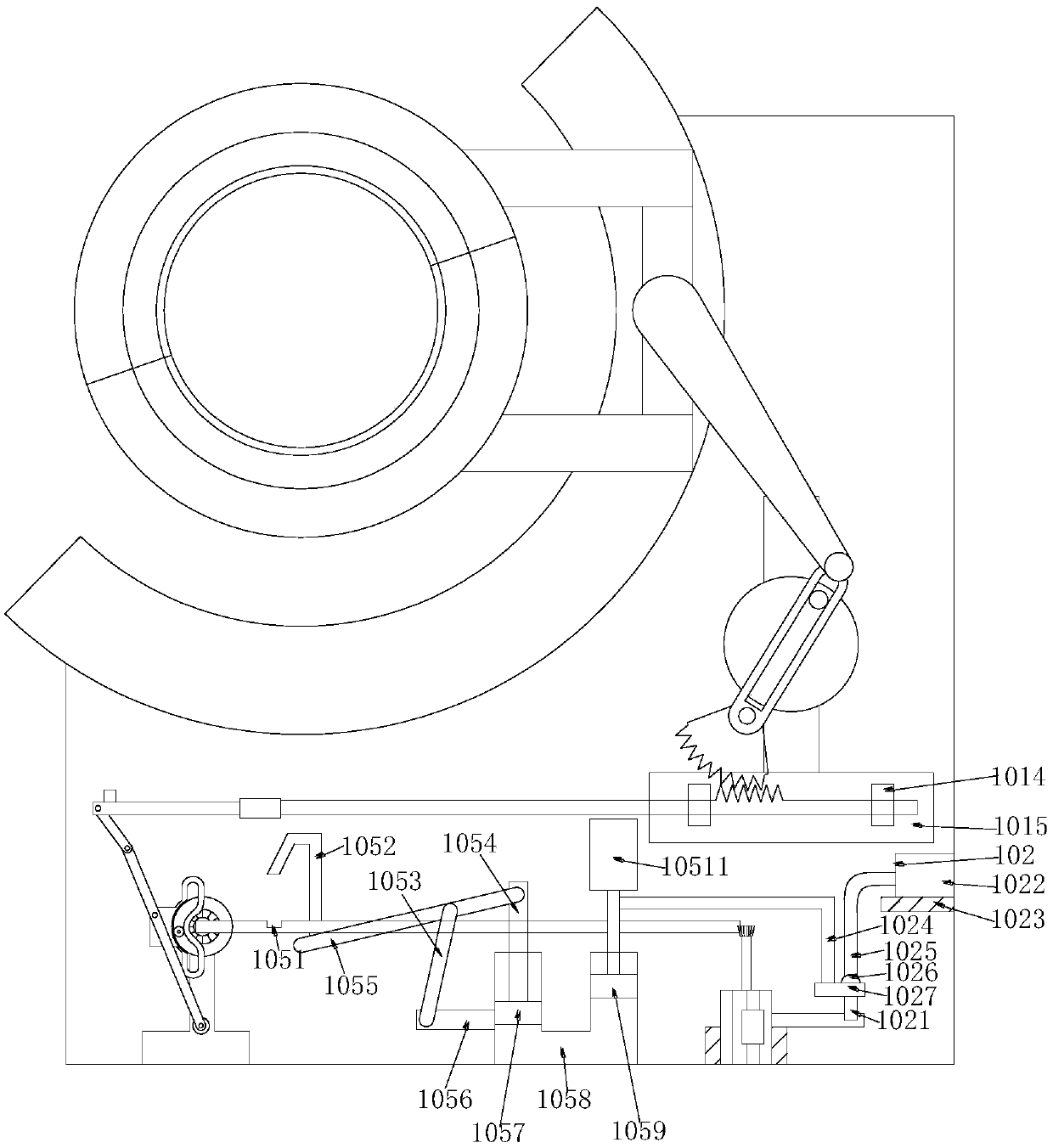

[0027] see Figure 1-Figure 5 , the present invention provides a scraper device for cleaning drying cylinders during papermaking, its structure includes a scraper control mechanism 1, a scraper device 2, and a fixing seat 3, the scraper control mechanism 1 is mechanically coordinated with the scraper device 2, and the scraper device 2 is installed on the fixed seat 3 and mechanically cooperates with the fixed seat 3, and the fixed seat 3 is provided with a scraper control mechanism 1;

[0028] The scraper control mechanism 1 is composed of a mechanical meshing structure 101, a power device 102, a scraper rotating device 103, an meshing structure driving device 104, a rotating shaft control device 105, and a driving device 106;

[0029] The mechanical engagement structure 101 is mechanically connected to the scraper rotation device 103, the scraper rotation device 103 is mechanically coordinated with the scraper device 2, and the scraper rotation device 103 is mechanically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com