Multi-stage buffering highway barrier structure

A technology for expressways and guardrail structures, applied to roads, roads, road safety devices, etc., can solve the problem of limited deformation capacity and energy absorption capacity of guardrails, limited deformation capacity and energy absorption capacity, and secondary safety problems of vehicles and crew members. Injury and other problems, to achieve the effect of strong practicability, improve deformation ability, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

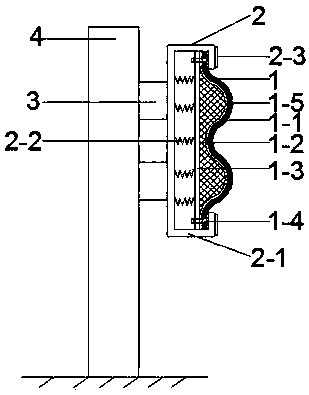

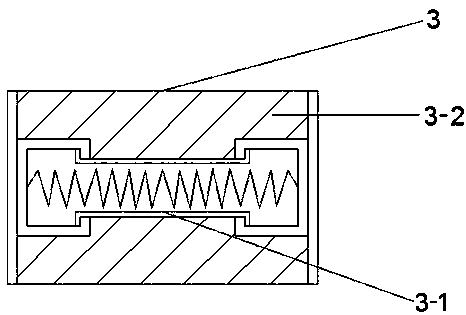

[0021] Example: such as figure 1 As shown, the multi-level buffer highway guardrail structure includes the first buffer part 1, the second buffer part 2, the connecting part 3 and the column 4; the first buffer part 1 is located on the side close to the road, and is stuck on the second buffer part In 2, the outer wall of the groove-shaped base 2-1 of the second buffer part 2 is fixedly connected with the upper and lower connecting parts 3, and the other end of the connecting part 3 is fixedly connected with the column 4, and the column 4 is made of cement or steel;

[0022] The first buffer part 1 includes the anti-collision guardrail board 1-1, the filling layer 1-2, the shock absorbing plate 1-3, and the bolt 1-4 from the outside to the inside; the side of the first buffer part 1 close to the road is an anti-collision guardrail Plate 1-1, the anti-collision guardrail 1-1 is made of metal material, the upper and lower sides of the anti-collision guardrail 1-1 have two symmetr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap