Insulation type sensor connecting shaft

A sensor and connecting shaft technology, which is applied in the field of insulating sensor connecting shaft, can solve the problems of sensor damage, large inertia of rotation transmission and low mechanical efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

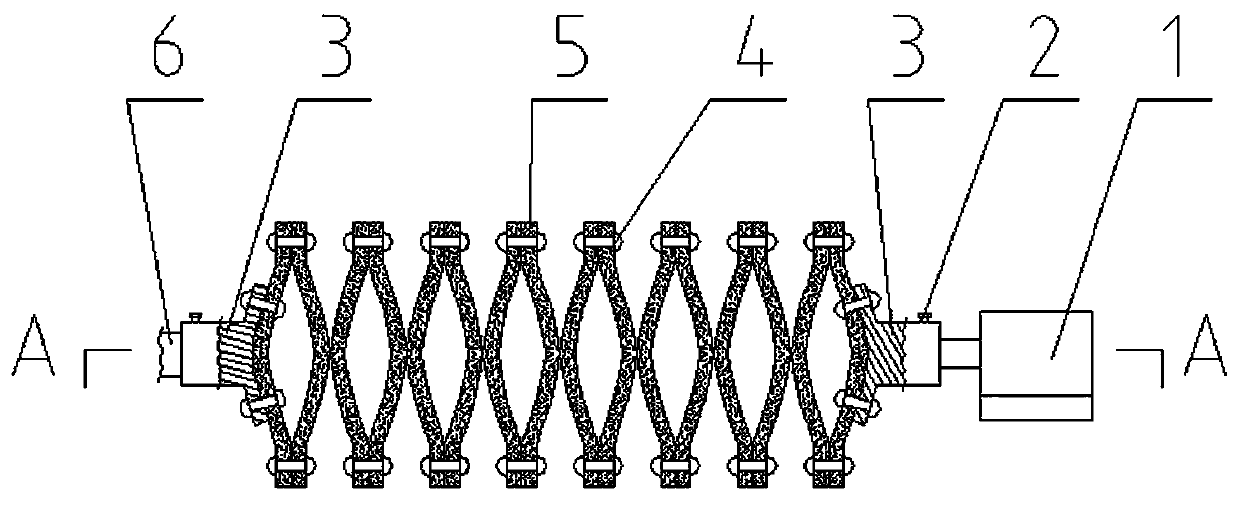

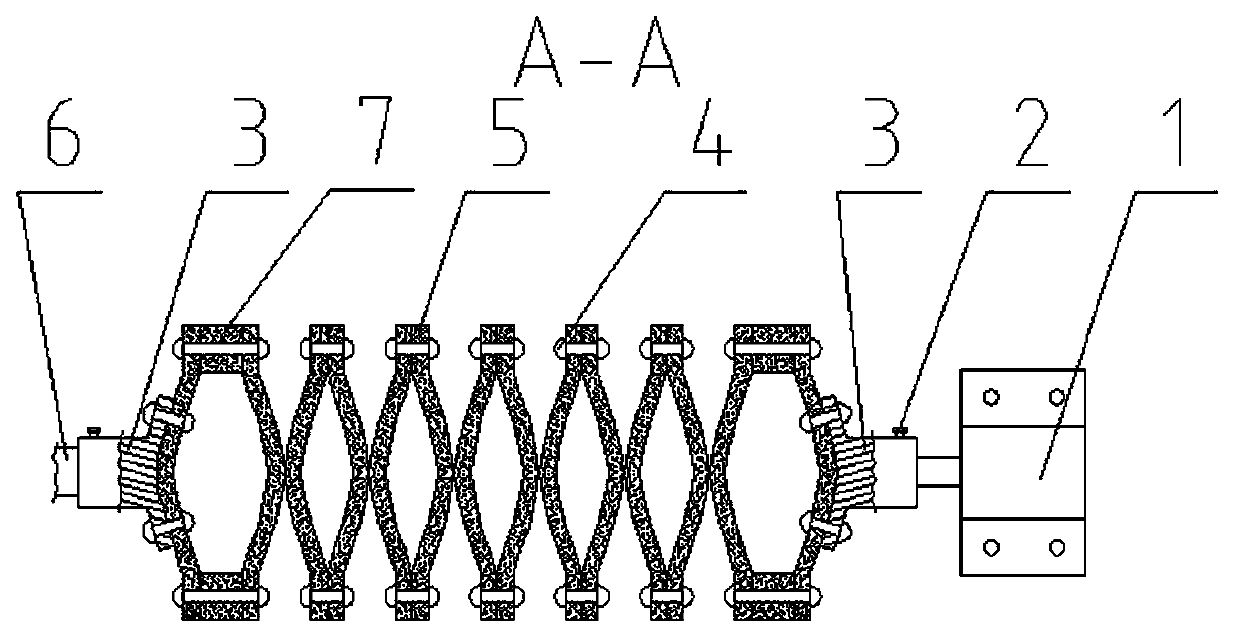

[0009] Such as figure 1 , figure 2 As shown, the insulated sensor connection shaft of the present invention mainly includes a sensor 1 and a rotary output shaft 6 . A film body 5 is installed between the sensor 1 and the rotary output shaft 6, and the film body 5 is connected by rivets 4 distributed in a cross shape at intervals. Both ends of the outermost film body 5 are equipped with connectors 3 and bolts 2 to be connected to the rotary output shaft 6 and the sensor 1 respectively.

[0010] Such as figure 1 , figure 2 As shown, in order to make the outermost film body 5 and the connector 3 better balancedly connected, a spacer sleeve 7 is also installed between the outermost film bodies.

[0011] Such as figure 1 , figure 2 As shown, when manufacturing and using the present invention, the shaft body should undergo relatively high-precision dynamic balance calibration and compensation treatment after the manufacturing and processing of the shaft body is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com