A kind of preparation method of rubber sheath cable and cable sheath

A cable sheath and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor flex resistance and softness, restrict the application and development of cables, and fail to meet market demand, etc., and achieve good flame retardancy , Stripping is convenient and fast, and the effect of avoiding damage to the conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

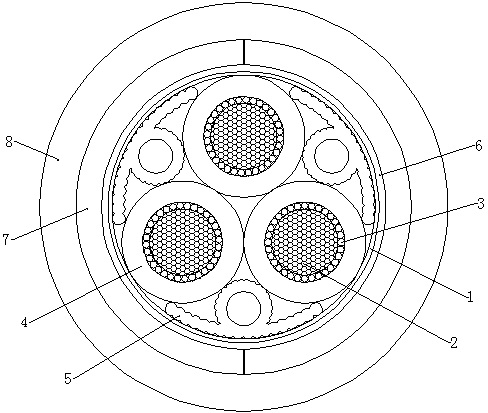

[0021] Embodiment 1, a rubber-sheathed cable, comprising a tape layer 1, the outside of the tape layer 1 is covered with an aluminum tape armor layer 6, and the outside of the aluminum tape armor layer 6 is covered with a nano-sponge layer 7, The outside of the nano-sponge layer 7 is covered with a cable sheath 8, and the inner circumference of the tape layer 1 is evenly distributed with conductive cores 2 and cable filling strips 5, and the conductive cores 2 and cable filling strips 5 are alternately arranged at intervals, The outer side of the conductive core 2 is coated with an insulating layer 4, and an insulating strip layer 3 is arranged between the conductive core 2 and the insulating layer 4; the number of the conductive core 2 and the cable filling strip 5 are the same, and the number All are 3; the nano-sponge layer 7 is composed of two identical semicircular tubular structures; the insulating strip layer 3 is made of the same material as the insulating layer 4, and ...

Embodiment 2

[0027] Embodiment 2, a rubber-sheathed cable, comprising a tape layer 1, the outside of the tape layer 1 is covered with an aluminum tape armor layer 6, and the outside of the aluminum tape armor layer 6 is covered with a nano-sponge layer 7, The outside of the nano-sponge layer 7 is covered with a cable sheath 8, and the inner circumference of the tape layer 1 is evenly distributed with conductive cores 2 and cable filling strips 5, and the conductive cores 2 and cable filling strips 5 are alternately arranged at intervals, The outer side of the conductive core 2 is coated with an insulating layer 4, and an insulating strip layer 3 is arranged between the conductive core 2 and the insulating layer 4; the number of the conductive core 2 and the cable filling strip 5 are the same, and the number All are 3; the nano-sponge layer 7 is composed of two identical semicircular tubular structures; the insulating strip layer 3 is made of the same material as the insulating layer 4, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com